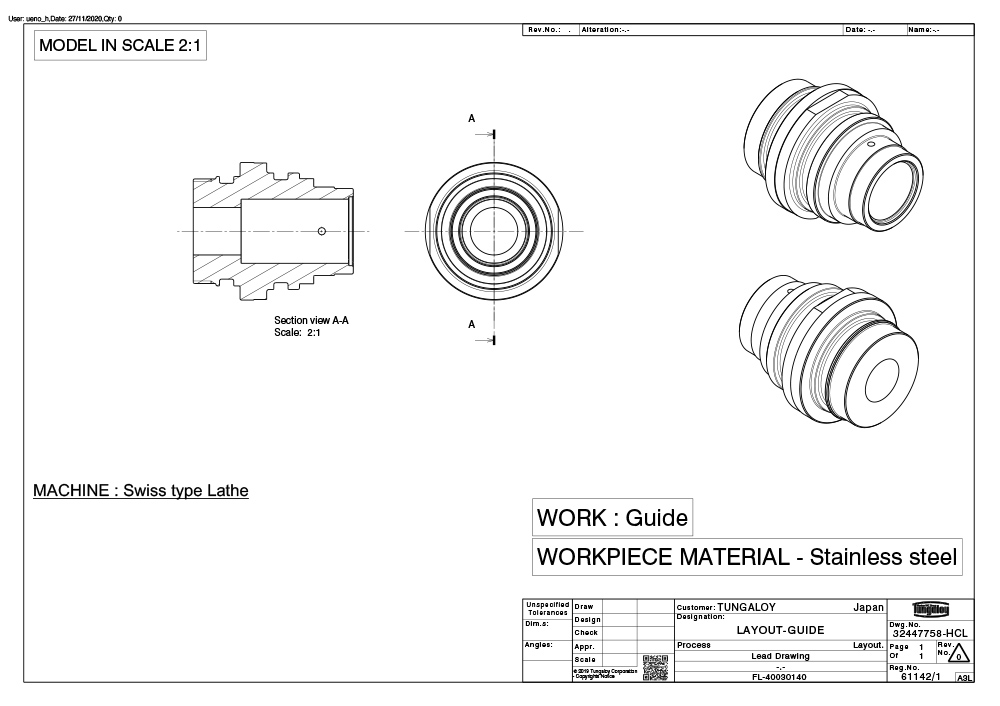

Automotive – Guide

The primary roles of guides are diverse, including positioning of physical parts or systems, motion control, reduction of wear, ensuring stability, and shock absorption.

Automobiles consist of numerous components, and due to increasing demands for higher precision in parts used in engines, transmissions, suspensions, and pumps—as well as in small and electronic components—cutting tools are now required to meet high standards in terms of appearance, accuracy, and adaptability to a wide variety of part types.

Moreover, these demands are not limited to the automotive industry. They span a wide range of sectors from everyday items to industrial applications, including precision equipment components, machine parts (such as those used in semiconductor manufacturing equipment), aircraft, medical devices, and optical communication components.

Tungaloy has been actively engaged in research on machining technologies to respond to this expanding demand for Swiss-type automatic lathe processing and has earned high praise from customers.

Tooling concepts

- Stabilization and increased efficiency of cutting processes for mass production parts

- Achieves high-speed, stable, and efficient machining through the use of internally coolant-fed tooling

- Significantly reduces tool change time, improving overall productivity

- Contributes to stable mass production by greatly enhancing vibration resistance through optimal tool overhang settings

Featured process

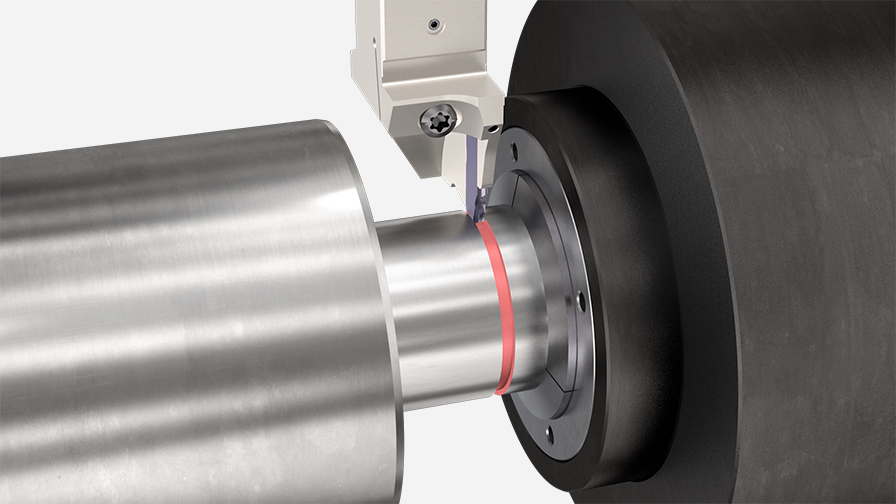

Process 1: Parting-off

Benefits

- By adopting a unique arc-shaped insert seat in the TungCut system, clamping rigidity is dramatically enhanced, resulting in superior vibration resistance and machining accuracy for highly stable cutting performance

- Coolant can be supplied from two directions—both the rake face and flank face of the cutting edge

- The effect of high-pressure coolant helps to dissipate cutting heat, suppress tool damage, and achieve improved chip evacuation and extended tool life

- Unique land geometry and specially designed breaker shape provide low cutting resistance and excellent sharpness!

- Inserts with lead angle are also available to minimize center remaining material

- A multifunctional grooving tool series that meets a wide range of grooving process requirements

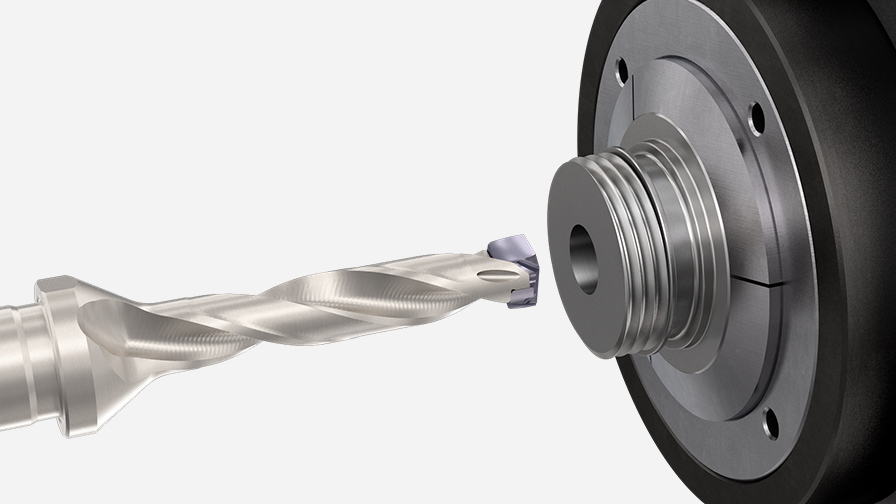

Process 2: Hole making

Benefits

- DrillMeister is a revolutionary exchangeable-head drill that combines the performance of solid drills with the convenience of indexable tooling

- The drill head features a unique self-clamping system that enables quick and easy head replacement

- The drill head offers long and stable tool life without the need for regrinding or recoating, making it ideal for reducing machining costs

DMP head

- Drill head with a 140° point angle suitable for a wide range of hole-making applications

- Sharp cutting edge design ensures low cutting resistance and extended tool life

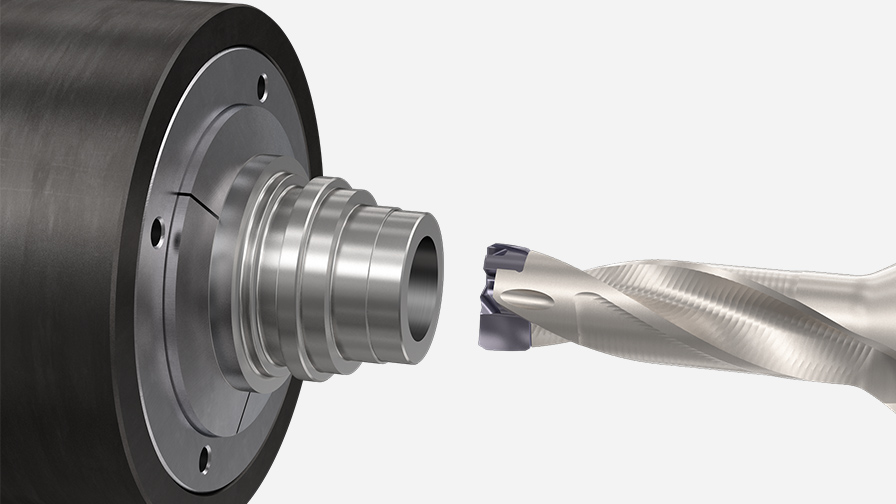

Process 3: Hole making

Benefits

- DrillMeister is a revolutionary exchangeable-head drill that combines the performance of solid drills with the convenience of indexable tooling

- The drill head features a unique self-clamping system that enables quick and easy head replacement

- The drill head offers long and stable tool life without the need for regrinding or recoating, making it ideal for reducing machining costs

DMF head

- The 180° point angle of the main cutting edge is ideal for machining flat-bottom holes

- Equipped with a self-centering cutting edge that enhances initial bite and delivers excellent hole accuracy

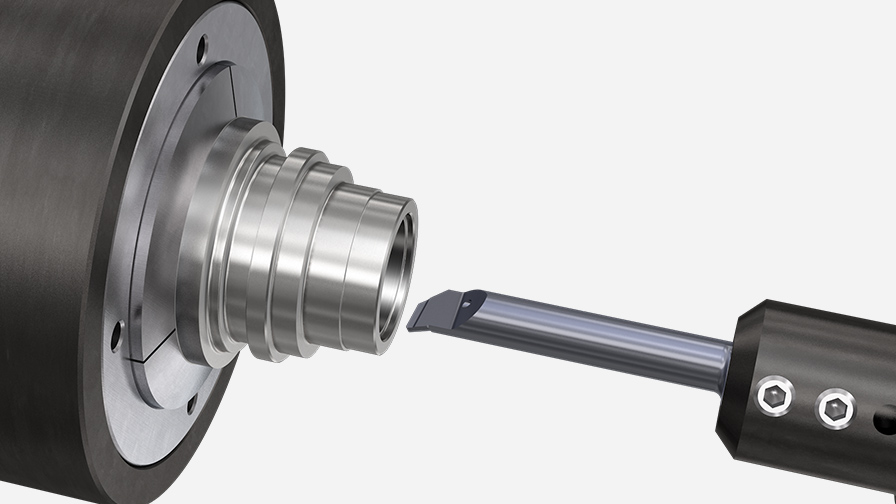

Process 4: Finish internal turning

Benefits

- TinyMini-Turn is a superhard solid bar series with excellent performance and a rich lineup, supporting a wide variety of ultra-small diameter internal machining operations

- The lineup is compatible with internal coolant supply. Coolant can be directed precisely to the cutting point, providing excellent chip evacuation even in ultra-small diameter machining

- A combination of advanced grinding technology and smooth coating offers outstanding edge sharpness. This enables high precision and high-quality machining in ultra-small diameters, while also contributing to stable tool life

![]()

- An optimal grade for small-part machining, offering both sharp cutting performance and long tool life

- Excellent wear resistance and chipping resistance ensure stable and extended tool life

- By applying the SH725 grade to the coolant-through solid bar series, both improved chip evacuation and stable long tool life are achieved simultaneously

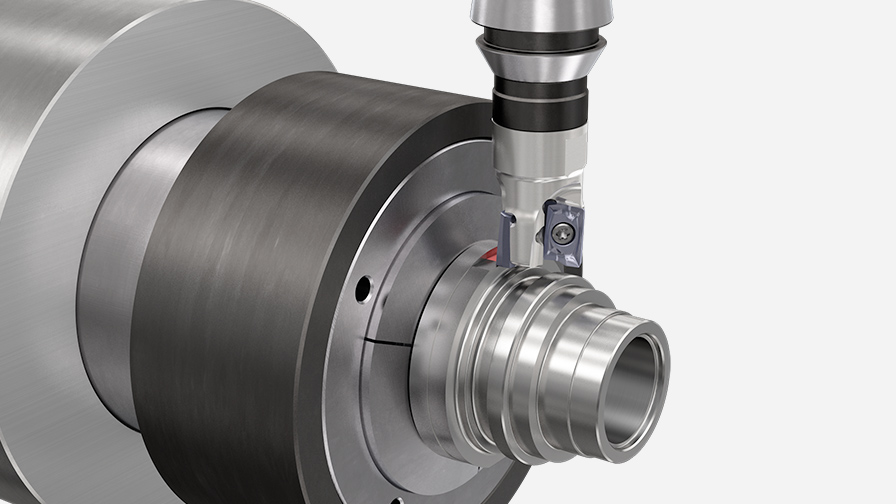

Process 5: Finish shoulder milling

Benefits

- By combining a small-diameter modular head with a high-rigidity integrated collet holder, optimal tool overhang can be achieved, suppressing vibration and enabling high-precision machining

- Since the protrusion length from the collet face can be selected, the most suitable tool setup can be chosen according to the machining conditions

- A large rake angle combined with a reverse-positive flank geometry design provides both low cutting resistance and excellent chipping resistance

- The insert’s V-shaped bottom surface retains core thickness while increasing the back metal thickness, resulting in high body rigidity

- With a unique cutting edge design and enhanced body rigidity, it is possible to achieve wall surface accuracy comparable to that of a solid end mill

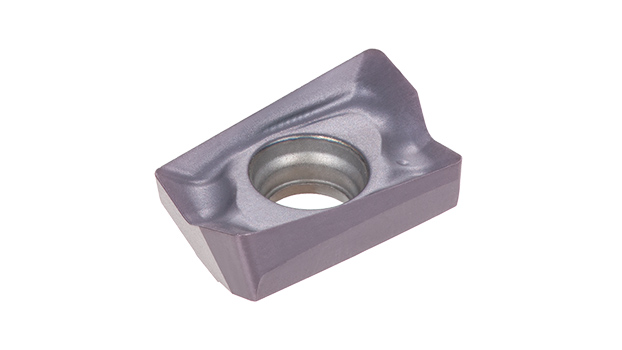

![]()

AVGT06

- Maximum depth of cut: 6 mm

- The V-shaped insert bottom suppresses any unwanted insert movement, improving wall surface accuracy and machined surface quality