多功能扩孔刀,拥有丰富的刀具直径规格

丰富的刀具直径规格满足各种孔加工需求

应用 & 特点

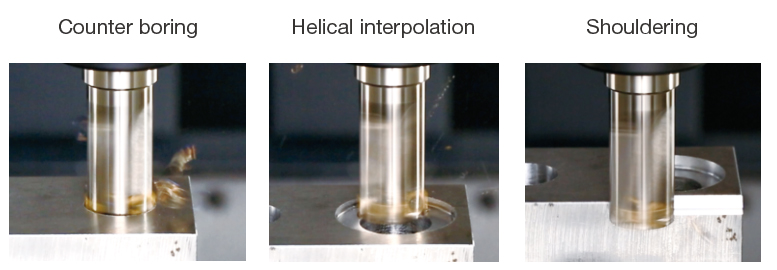

应用

特点

1. 用于各种扩充加工的丰富刀具阵容

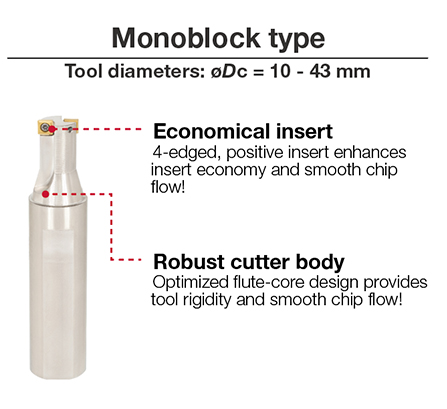

2. 2款立铣刀可选

• 整体式: ø10 – ø43mm

• 刀夹式: ø26 – ø59mm, 使用垫片调节直径

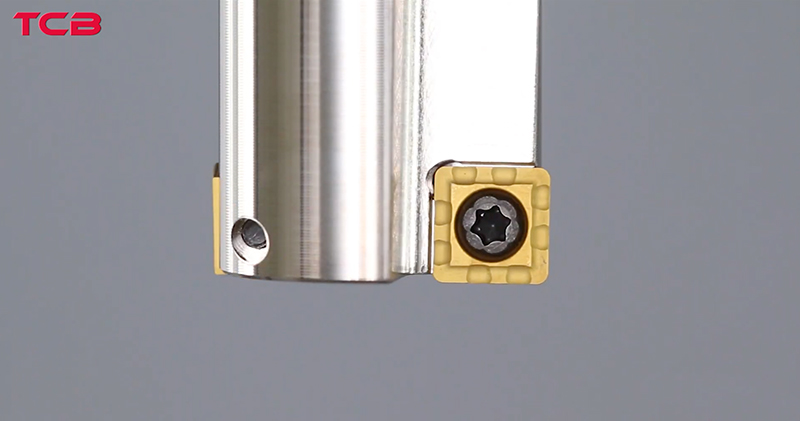

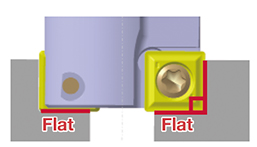

3. 加工90°平底面

4. 多功能

刀片 & 材质

刀体

成功案例

案例 #1

汽车行业

| 零件: | 连杆 |

| 材料: | S55C / C55 |

| 钻头: | TCB170F25 |

| 刀片: | SPMP831DS |

| 材质: | T313W |

| 加工条件: | Vc = 160 (m/min) f = 0.2 (mm/rev) Vf = 600 (mm/min) H = 24 (mm) 应用: 镗孔 冷却方式: 冷却液 机床: 专机 |

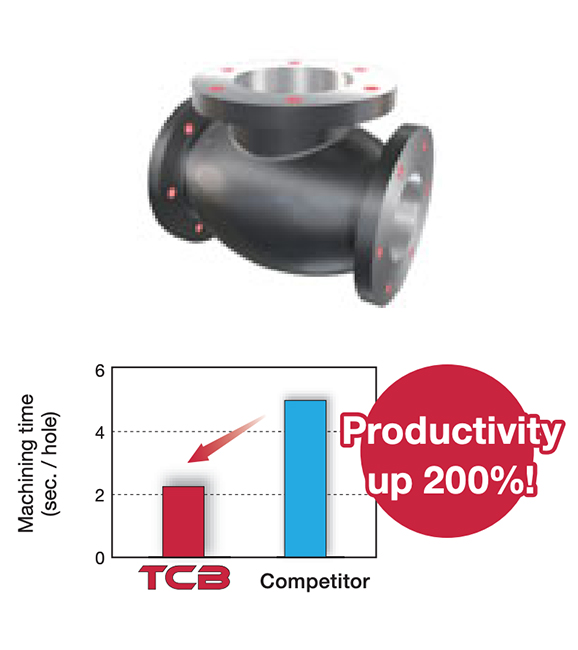

案例 #2

通用工程

| 零件: | 阀门 |

| 材料: | FC250 / GG25 / 250 |

| 刀杆: | TCB240F25 |

| 刀片: | SPMP042ERD |

| 材质: | T313W |

| 加工条件: | Vc= 180 (m/min) f= 0.3 (mm/rev) Vf= 720 (mm/min) H= 30 (mm) 应用: 镗孔 冷却方式: 冷却液 机床: 卧式加工中心, BT50 |

案例 #3

通用工程

| 零件: | 轴承 |

| 材料: | S45C / C45 |

| 刀杆: | TCB-320 |

| 刀片: | SPMM322ERD |

| 材质: | T313W |

| 加工条件: | Vc= 150 (m/min) f= 0.25 (mm/rev) Vf= 375 (mm/min) H= 40 (mm) 应用: 镗孔 冷却方式: 冷却液 机床: 数控车床 |

标准加工条件

Counter boring

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed : f (mm/rev) | |

|---|---|---|---|---|---|

| ø10 – 12 (z = 1) | ø13 – 59 (z = 2) | ||||

|

Carbon steel | – 300 HB | 80 – 200 | 0.03 – 0.08 | 0.1 – 0.3 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.03 – 0.05 | 0.06 – 0.15 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.05 – 0.1 | 0.1 – 0.4 |

|

Non-ferrous | – | 100 – 300 | 0.05 – 0.2 | 0.1 – 0.4 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.03 – 0.05 | 0.06 – 0.15 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.03 – 0.05 | 0.06 – 0.15 |

Milling

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

|

Carbon steel | – 300 HB | 80 – 200 | 0.05 – 0.15 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.05 – 0.1 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.05 – 0.2 |

|

Non-ferrous | – | 100 – 300 | 0.1 – 0.2 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.05 – 0.08 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.05 – 0.08 |

Internal boring (With one cutting edge)

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed fz (mm/t) |

|---|---|---|---|---|---|

|

Carbon steel | – 300 HB | 80 – 200 | 0.5 – | 0.05 – 0.15 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.5 – | 0.05 – 0.1 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.5 – | 0.05 – 0.2 |

|

Non-ferrous | – | 100 – 300 | 0.5 – | 0.1 – 0.2 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.5 – | 0.05 – 0.08 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.5 – | 0.05 – 0.08 |