高通用性新一代大进给铣刀

特殊的刀片设计允许改变主偏角

可以为不同工件材料的加工选择最佳的切深

应用 & 特点

应用

特点

1. 2种类型的刀片可以分别安装在同一款刀体上从而获得不同的主偏角

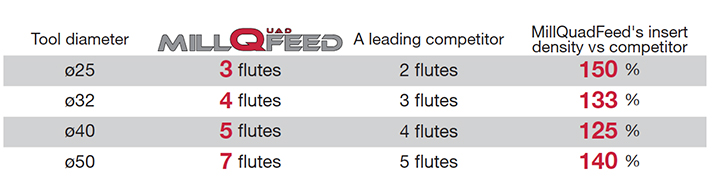

2. 高效的密齿型设计

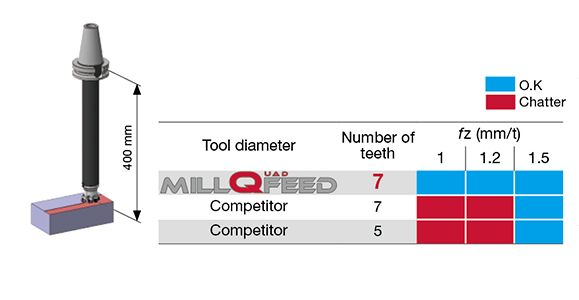

3. 出色的抗振稳定性

刀片 & 材质

刀片

主要材质

刀体

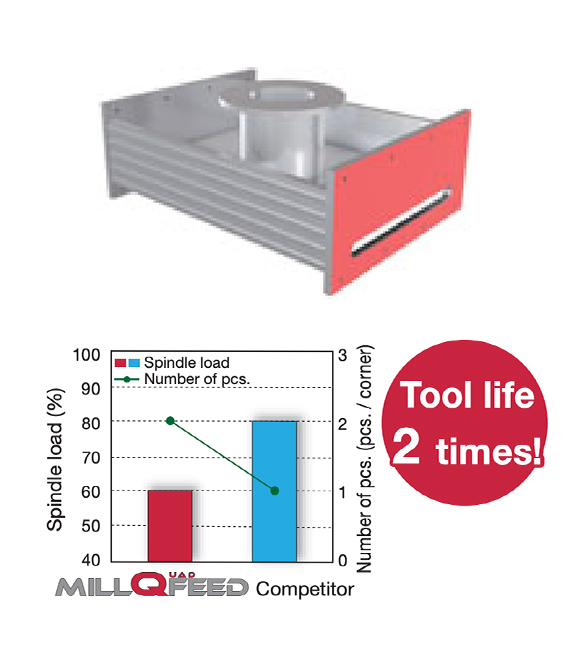

实际案例

案例 #1

航空航天

| 零件: | 连杆端轴承零件 |

| 材料: | 17-4PH (PH stainless steel, 38HRC) |

| 刀杆: | EXSW09M032C32.0R04 (ø32, z=4) |

| 刀片: | SWMT0904UER-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 200 (m/min) fz = 0.75 (mm/t) ap = 0.6 (mm) ae = 13 (mm) 应用: 平面铣削 冷却方式: 冷却液 机床: 多功能机床 |

案例 #2

通用工程

| 零件: | 磁性吸盘 |

| 材料: | SS400 / E275A |

| 刀杆: | EXSW09M025C25.0R03 (ø25, z=3) |

| 刀片: | SWMT0904UER-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 274 (m/min) fz = 0.83 (mm/t) ap = 0.7 (mm) ae = 25 (mm) 应用: 切槽 冷却方式: 冷却液 机床: 卧式加工中心, BT50 |

案例 #3

通用工程

| 零件: | 腔体 |

| 材料: | SUS304 / X5CrNi18-9 |

| 刀盘: | TXSW15J160B50.8R08 (ø160, z=8) |

| 刀片: | SWMT1506ZER-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 150 (m/min) fz = 1 (mm/t) ap = 1 (mm) ae = 130 (mm) 应用: 端面铣削 冷却方式: 干切 机床: 卧式加工中心, BT50, 22kW |

标准加工条件

09 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Wear resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Austenitic stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Fracture resistance | UER | AH130 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc., 250, 300, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Ductile cast iron FCD600, etc., 600-3, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Wear resistance | UER | AH8015 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Low cutting force | ZER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Fracture resistance | USR | AH8015 | Flat top | 20 – 50 | 0.1 – 0.3 | ||||

| Low cutting force | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Fracture resistance | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| Low cutting force | ZSR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||

15 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 2 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.2 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Austenitic stainless steel SUS304, etc., X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 80 – 200 | 0.5 – 1.5 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Low cutting force | ZER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||