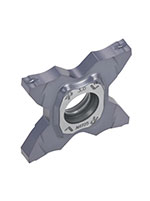

安装4刀尖刀片的槽刀

研磨刀片锁紧在特殊的刀片座内实现高刚性和重复定位精度。

应用 & 特点

应用

特点

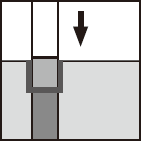

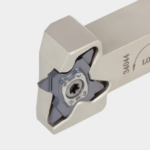

1. 特殊的3点锁紧系统

特殊的刀片座设计实现了转位重复定位精度和精确的刀尖高度。

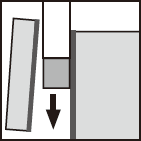

2. 研磨和压铸断屑槽

丰富的阵容提高了灵活性。

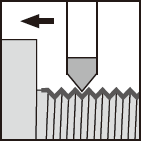

3. 非标刀片快速交货服务

刀片 & 材质

刀片

材质

刀杆

实际案例

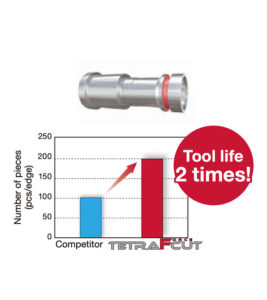

案例 #1

通用工程

| 零件: | 轴定子 |

| 材料: | S45C / C45 |

| 刀杆: | STCR2525-27 |

| 刀片: | TCS27-200-020 |

| 材质: | AH725 |

| 加工条件: | Vc = 210 (m/min) f = 0.15 (mm/rev) CDX = 2 (mm) CW = 2 (mm) 应用: 外圆切槽 冷却方式: 冷却液 机床: 数控车床 |

案例 #2

汽车行业

| 零件: | 输入轴 |

| 材料: | SCr420 / 20Cr4 |

| 刀杆: | STCR2525Z18 |

| 刀片: | TCG18R150-020 |

| 材质: | AH7025 |

| 加工条件: | Vc = 100 (m/min) f = 0.08 (mm/rev) CDX = 2.1 (mm) CW = 2 (mm) 应用: 外圆切槽 冷却方式: 冷却液 机床: 数控车床 |

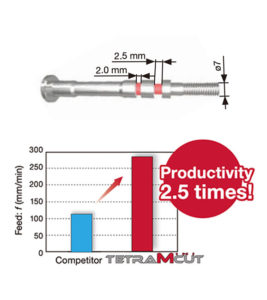

案例 #3

小零件/电子行业

| 零件: | 线轴 |

| 材料: | S45C / C45 |

| 刀杆: | STCR1010X18 |

| 刀片: | TCP18R200F-010 |

| 材质: | SH725 |

| 加工条件: | Vc = 43 (m/min) f = 0.10 (mm/rev) CDX= 1.5 / 1.1 (mm/min) CW = 2 / 2.5 (mm) 应用: 外圆切槽 冷却方式: 冷却液 机床: 瑞士机床 |

标准加工条件

TCL18R/L, TCS18R/L (3D chipbreaker), TCG18R/L (honed edge), TCG18R/L (Full R)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|---|

| TCL18 | TCS18 | TCG18 | ||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 100 – 200 | |||||

| AH6235 | 80 – 120 | |||||

| NS9530 | 120 – 250 | |||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 100 – 200 | |||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 80 – 120 | |||||

| AH6235 | 50 – 120 | |||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 50 – 180 | |||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 120 | |||||

| AH6235 | 50 – 80 | |||||

| NS9530 | 50 – 180 | |||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 30 – 60 | |||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 20 – 50 | |||||

TCP18R/L (lightly honed edge) / TCP18R/L-F (sharp edge)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.08 | |

| AH725 | 50 – 120 | 0.03 – 0.1 | ||

| Grey cast iron FC250 / 250, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Ductile cast iron FCD400 / 400-15, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.08 | |

| AH725 | 30 – 80 | 0.03 – 0.1 | ||

| Superalloys Inconel718, etc. |

SH7025 | 20 – 60 | 0.01 – 0.08 | |

| AH725 | 20 – 60 | 0.03 – 0.1 |

TCF18L (Face grooving)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Grey cast iron FC250 / 250, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Ductile cast iron FCD400 / 400-15, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 20 – 40 | 0.01 – 0.04 | |

| Superalloys Inconel718, etc. |

SH7025 | 10 – 30 | 0.01 – 0.04 |

TCT18R/L / TCT18FR

| ISO | Workpiece material | Hardness | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200HB | AH8015 | 80 – 180 | |

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| > 200HB | AH8015 | 60 – 160 | ||

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | AH8015 | 50 – 130 | |

| – | AH725 | 50 – 80 | ||

| – | SH7025 | 50 – 80 | ||

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | AH8015 | 60 – 150 | |

| – | AH725 | 50 – 100 | ||

| – | SH7025 | 50 – 100 | ||

| Superalloys Ti-6AI-4V, Inconel718, etc. |

– | AH8015 | 20 – 80 | |

| – | AH725 | 20 – 80 | ||

| – | SH7025 | 20 – 80 |

TCL27, TCS27, TCM27, TCG27, TCL38

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut for profiling (with full radius insert) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grooving, Parting off |

Parting off (with hand) |

Profiling (with full radius insert) |

|||||||||

| TCL | TCS | TCM | TCG | TCS | TCS | TCM | |||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 100 – 200 | ||||||||||

| AH6235 | 80 – 120 | ||||||||||

| NS9530 | 120 – 250 | ||||||||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 100 – 200 | ||||||||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 80 – 120 | ||||||||||

| AH6235 | 50 – 120 | ||||||||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 120 | ||||||||||

| AH6235 | 50 – 80 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 30 – 60 | ||||||||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 20 – 50 | ||||||||||

1QP-TCX18R/L (Widening external grooves)

| ISO | Workpiece materials | Hardness | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut: ae (mm) | ||

|---|---|---|---|---|---|---|---|---|

| RE = 0.1 | RE = 0.2 | RE = 0.1 | RE = 0.2 | |||||

| Hard material · Hardened steel SCM435 / 34CrMo4, SUJ2 / B1 etc. |

> 50 HRC | BX360 | 80 – 150 | 0.02 – 0.05 | 0.03 – 0.1 | 0.15 – 0.3 | 0.15 – 0.5 | |