用于数控自动车床和凸轮驱动车床的灵活车刀系列

适用于12mm或更小直径小零件的加工

应用 & 特点

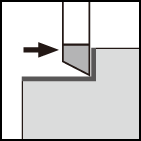

应用

特点

拥有可用于凸轮驱动和数控自动车床所有的刀杆尺寸

- 优化的锁紧螺钉使加工时刀片的移动最小化

- 研磨的接触面使刀片拥有优秀的重复定位精度

- 6 x 6 到 10 x 10 mm 标准刀杆可选

- 创新的刀片锁紧机构允许在尺寸不同的所有刀杆上使用相同的刀片

- 平坦的刀杆设计避免了在刀塔上刀具之间的干涉,实现自由的刀具安装

适用范围广

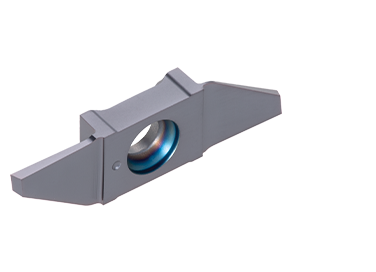

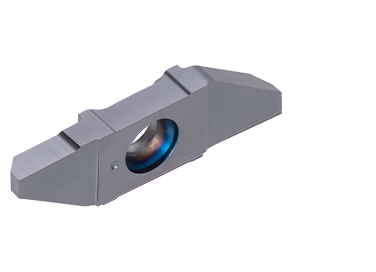

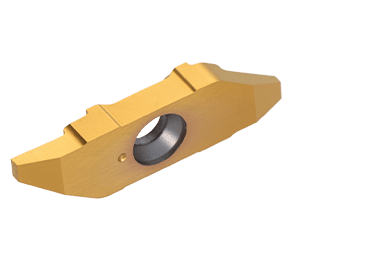

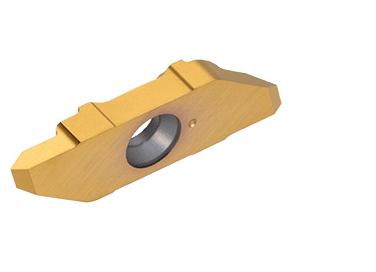

- 可提供标准的切断和前车刀片

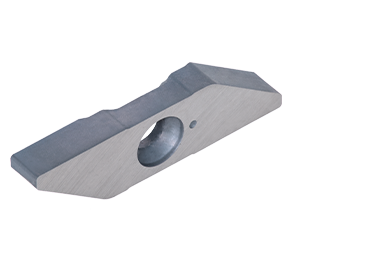

- 客户还可以使用毛坯刀片将其自由制造成所需的槽形

- 即使在加工时刀尖发生崩损,其它未使用的刀尖也能够得到特殊锁紧系统的安全保护

- 右手和左手刀片

刀片 & 材质

刀杆

实际案例

案例 #1

| 零件: | 引擎零件 |

| 材料: | SUS316L |

| 刀杆: | JSXXR0707X05 |

| 刀片: | JVPN12R10F000-20 |

| 材质: | SH725 |

| 加工条件: | Vc = 75 (m/min) f = 0.03 (mm/rev) CW = 1 (mm) 应用: 切断 冷却方式: 油冷 |

案例#2

| 零件: | 计时器零件 |

| 材料: | SK4 |

| 刀杆: | JSXXR0808H05 |

| 刀片: | JVPN12R08F000-20 |

| 材质: | SH725 |

| 加工条件: | Vc = 50 (m/min) f = 0.01 (mm/rev) CW = 0.8 (mm) 应用: 切断 冷却方式: 油冷 |

标准加工条件

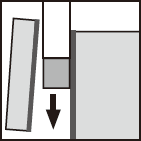

Back turning

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.03 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 | 0.01 – 0.03 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | 0.01 – 0.03 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.03 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 | 0.01 – 0.03 |

Grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.05 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 | 0.01 – 0.05 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | 0.01 – 0.05 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

Threading

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 |

切断加工

| ISO | 工件材料 | 材质 | 切削速度 Vc (m/min) |

进给 f (mm/rev) |

|---|---|---|---|---|

|

低碳钢 S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 |

| 碳钢,合金钢 S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 | |

| 易切钢 SUH22, SUH23, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 | |

|

不锈钢 SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 120 | 0.01 – 0.05 |

|

铝合金 A5056, A6061, etc. |

SH725 | 150 – 200 | 0.01 – 0.05 |

| 铜合金 C2600, C280C, etc. |

SH725 | 100 – 200 | 0.01 – 0.05 | |

|

钛合金 Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.01 – 0.05 |

| 超级合金 Inconel718, etc. |

SH725 | 30 – 80 | 0.01 – 0.05 |

前车

| ISO | 工件材料 | 材质 | 切削速度 Vc (m/min) |

进给 f (mm/rev) |

|---|---|---|---|---|

|

低碳钢 S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 |

| 碳钢,合金钢 S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 | |

| 易切钢 SUH22, SUH23, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 | |

|

不锈钢 SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 120 | 0.01 – 0.03 |

|

铝合金 A5056, A6061, etc. |

SH725 | 150 – 200 | 0.01 – 0.03 |

| 铜合金 C2600, C280C, etc. |

SH725 | 100 – 200 | 0.01 – 0.03 | |

|

钛合金 Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.01 – 0.03 |

| 超级合金 Inconel718, etc. |

SH725 | 30 – 80 | 0.01 – 0.03 |