2026 年 1 月,泰珂洛宣布将其 PVD 涂层材质 AH8015 的应用扩展到四种铣削刀具系列——DoForceTri、MillQuadFeed、TungTriShred 和 DoQuadMill——从而提高各种加工操作的耐磨性和刀具寿命。

挑战与趋势

在汽车、工程机械、航空航天和模具制造等广泛的行业中,对提高生产效率和降低成本的需求比以往任何时候都更加强烈。 特别是,在加工铸铁、耐热合金和淬硬钢等难切削材料时,由于磨损而频繁更换刀具成为提高生产率的主要障碍。

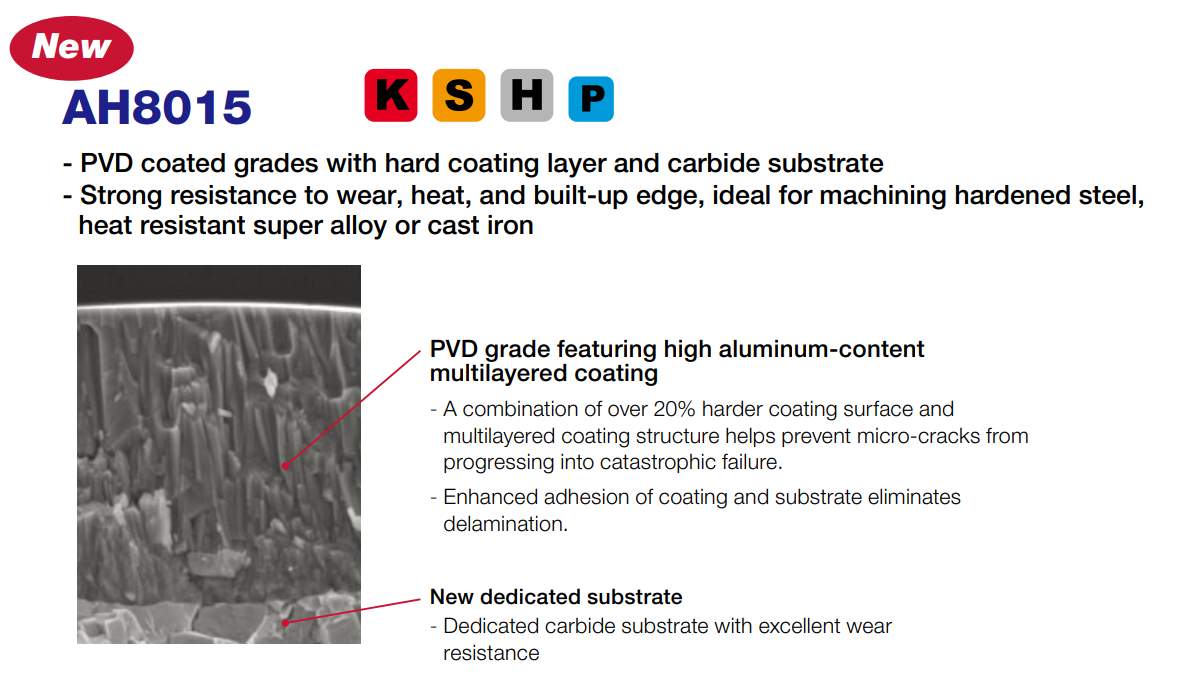

在这些市场条件下,对能够提供更长刀具寿命和稳定加工性能的高耐磨刀具的需求正在迅速增长。 为了应对这一挑战,Tungaloy 已将 PVD 涂层材质 AH8015 扩展到四种铣削刀具系列,从而在难切削材料加工中提供高可靠性和成本效益。|

产品概述

DoForce-Tri

应用:适用于台阶铣削与面铣的铣刀。

特点:

- 采用双面刀片,具备六个可用切削刃,以降低成本并提高生产率。

- 能够进行广泛加工,如台阶铣削和开槽。

- 曲线切削刃设计在保持良好排屑的同时降低切削阻力。

👉 适用于希望提升台阶铣削效率与经济性的应用。

TungTriShred

应用:适用于台阶铣削与开槽的高生产率粗加工铣刀。

特点:

- 锯齿状切削刃分割切屑,以抑制振颤。

- 同一刀体可使用两种类型的刀片。

- 即使在长悬伸条件下,也能实现稳定的高效率粗加工。

👉适用于希望抑制振刀并提升粗加工效率的场景。

DoQuadMill

应用:适用于包括贴近侧壁和拐角处的一般面铣加工的面铣刀。

特点:

- 采用八刃刀片,注重经济性与可达性。

- 支持从粗加工到精加工的面铣,同时避免干涉。

- 低阻力、低切削力的设计使其即使在工件不稳定的情况下也具有强适应性。

👉 适用于需要良好可达性的面铣及拐角加工刀具。

MillQuadFeed

应用:适用于大进给加工的铣刀。

特点:

- 同一刀体可安装两种不同切入角的刀片类型。

- 高刚性、低阻力设计可实现高效率加工与长刀具寿命。

- 支持包括台阶铣削和插铣在内的广泛应用。

👉 一款通用型铣刀,可通过改变切入角,实现针对不同应用的大进给加工。