Iwaki, Japan – June, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungCut series with the introduction of STX inserts featuring a 3D chipbreaker and PCD grade DX160, providing excellent chip control and surface finish in non-ferrous metal grooving applications.

Challenges and Trends

In grooving, parting, and lateral cutting operations on non-ferrous metals such as aluminum alloys, chips tend to become long and are prone to entangling with the workpiece or tool. This can lead to machine stoppages or tool breakage, causing significant issues. These problems are especially critical in environments where high-speed and high-precision machining is required, as they can severely hinder productivity and stable machining. However, conventional PCD insert products have offered few standard options with chip breakers to assist with chip control, leaving users without a fundamental solution.

Product Overview

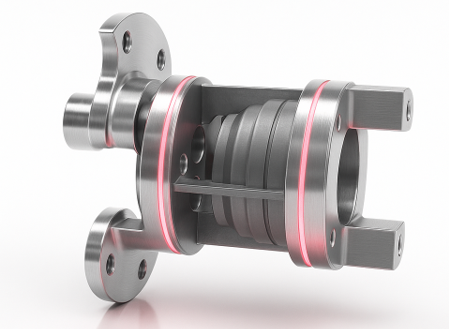

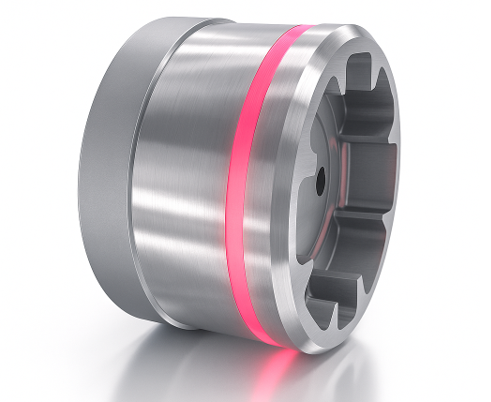

High-Precision and High-Efficiency Grooving and Parting Tool

TungCut delivers high-precision and stable performance in grooving and parting operations through excellent chip control and a high-rigidity clamping structure. It accommodates a wide range of workpiece shapes and machining conditions, achieving both high-efficiency machining and superior surface finishes.

Benefits and Features

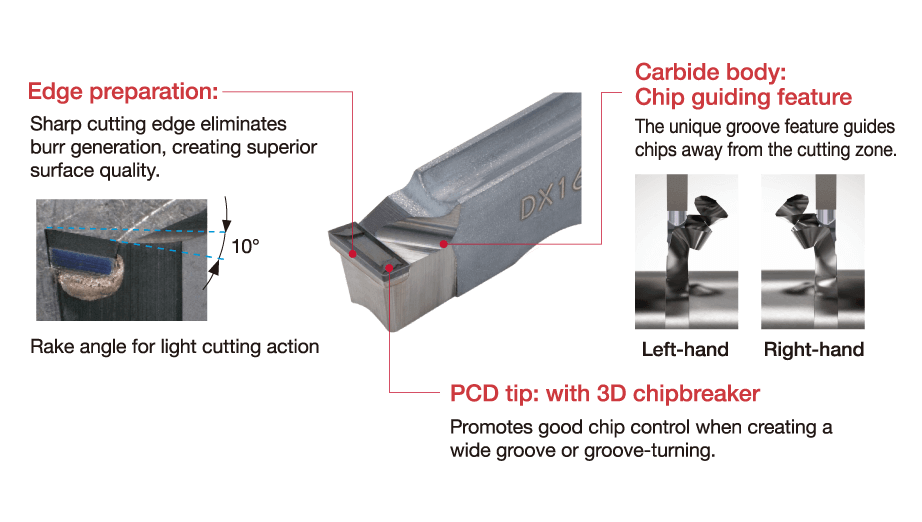

Feature 1: Superior Chip Control Performance with 3D Breaker

The dog-bone shaped 3D breaker effectively breaks chips during grooving and lateral feed operations.

Suppresses chip entanglement and clogging in a wide range of applications including external, internal, and face turning.

Enhanced machining stability supports automated lines and long-duration continuous operations.

Feature 2: Chip Flow Control with Carbide Insert Discharge Grooves and Handedness Options

Discharge grooves on the carbide insert smoothly guide chip flow.

Right-hand and left-hand versions allow chip discharge in the optimal direction for the machining process.

Controlled chip evacuation enhances surface finish and minimizes machining issues.

Feature 3: Adoption of High Wear-Resistant PCD Grade DX160

PCD grade DX160 is ideal for non-ferrous metal machining, achieving both long tool life and high-precision machining.

Demonstrates excellent wear resistance even with difficult-to-machine materials such as aluminum alloys.

Reduces tool change frequency, contributing to cost savings and improved productivity.

Cutting Performance

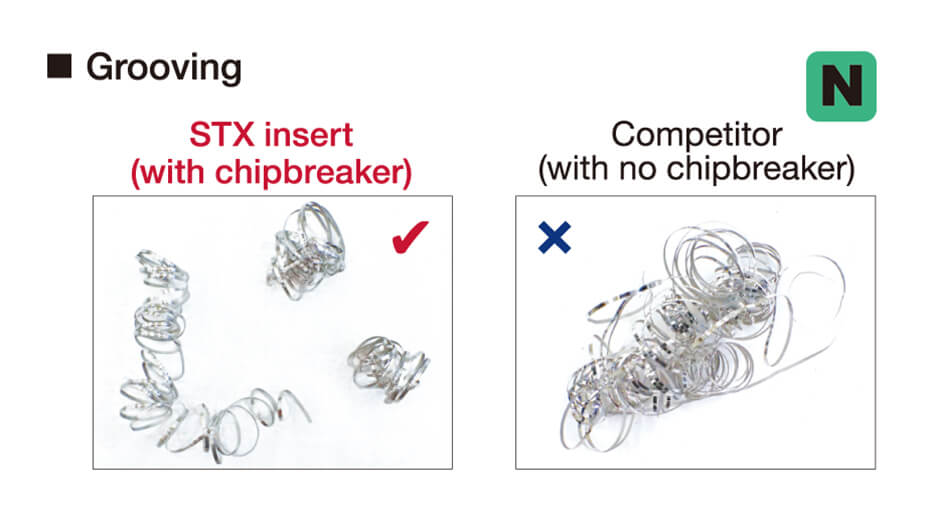

Chip control

| Insert | STX200L-020 DX160 |

| Toolholder | CTEL2525-2T17 |

| Workpiece material | A5056 |

| Cutting speed | Vc = 500 m/min |

| Feed | f = 0.15 mm/rev |

| Depth of cut | ap = 15 mm |

| Coolant | Wet |

STX insert, thanks to its optimized chip guide groove, allows smooth chip evacuation, while eliminating bird nest.

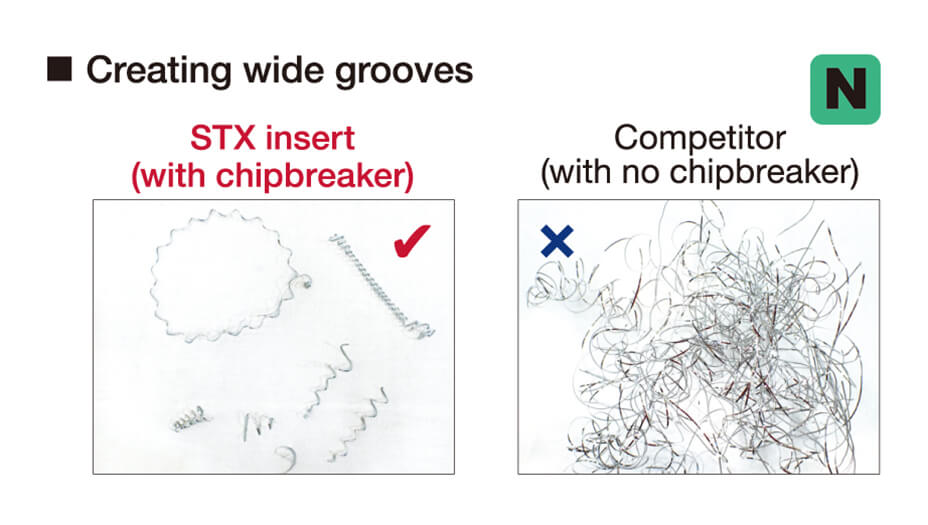

| Insert | STX200L-020 DX160 |

| Toolholder | CTEL2525-2T17 |

| Workpiece material | A5056 |

| Cutting speed | Vc = 500 m/min |

| Feed | f = 0.15 mm/rev |

| Depth of cut | ap = 0.7 mm |

| Coolant | Wet |

STX insert provides excellent chip control during cutting of a wide groove thanks to integrated 3D chipbreaker.

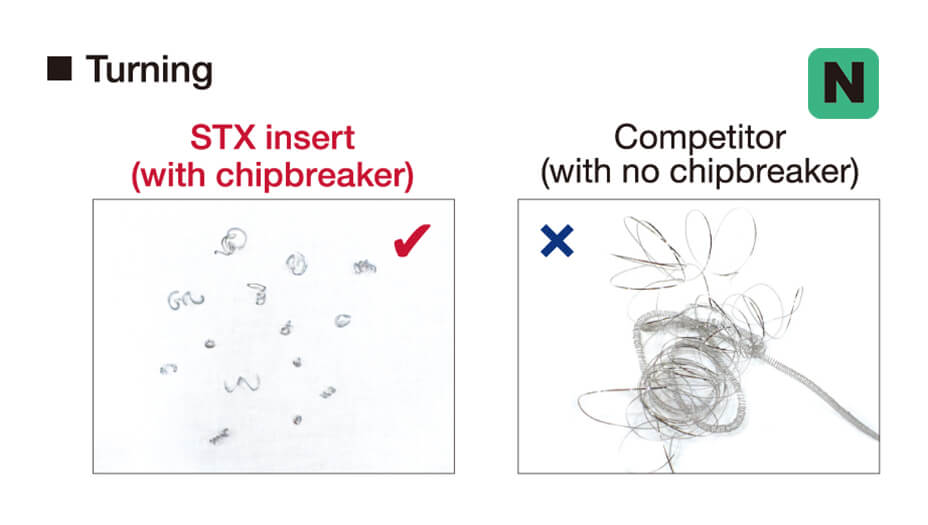

| Insert | STX200L-020 DX160 |

| Toolholder | CTEL2525-2T17 |

| Workpiece material | A5056 |

| Cutting speed | Vc = 500 m/min |

| Feed | f = 0.15 mm/rev |

| Depth of cut | ap = 0.5 mm |

| Coolant | Wet |

STX insert provides excellent chip control during groove-turning thanks to integrated 3D chipbreaker.

Success Stories

IMPROVED TOOL LIFE

The TungCut STX insert with PCD tip offers superior chip control and extended tool life compared to competitor inserts in grooving and turning operations.

This is achieved through its 3D chipbreaker design, which enhances chip evacuation and stability during cutting.

| Industry | Engineering |

| Component | Casing |

| Material ISO code | |

| Work material | ADC12 |

| Machine(Spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External grooving & turning |

| Product name | TungCut |

| TSR No. | 5248T |

IMPROVED TOOL LIFE AND CHIP CONTROL

The TungCut STX insert with PCD tip significantly improves chip control during grooving operations and offers up to 25 times longer tool life compared to competitor carbide inserts.

While competitor inserts suffered from chip entanglement and premature failure due to poor chip control, the 3D chipbreaker design of the STX insert ensures efficient chip control.

Combined with the wear resistance of PCD, this leads to remarkable tool life extension and process reliability.

| Industry | Aerospace |

| Component | Aerospace pump parts |

| Material ISO code | |

| Work material | A6061 |

| Machine(Spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TungCut |

| TSR No. | 5249T |