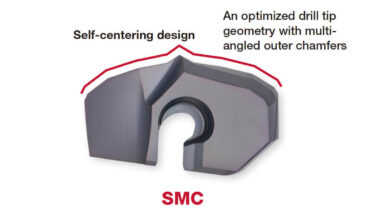

Iwaki, Japan – July, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DrillForce-Meister series, now featuring new SMC heads in diameters ø20–25.9 mm with secure screw-clamp mechanism and chamfered-edge geometry, ensuring burr-free deep hole drilling and extended tool life.

Challenges and Trends

In various industries such as structural steel construction, construction machinery, automobiles, molds, and shipbuilding, there is a growing demand for deep hole drilling in the ø20–25 mm range. However, conventional machining methods require pre-hole drilling, which leads to longer lead times and increased tool costs. Additionally, there have been cases where the drill head loosens during machining, negatively impacting machining stability and surface quality. As a result, there is a strong demand for products that can address these challenges.

Product Overview

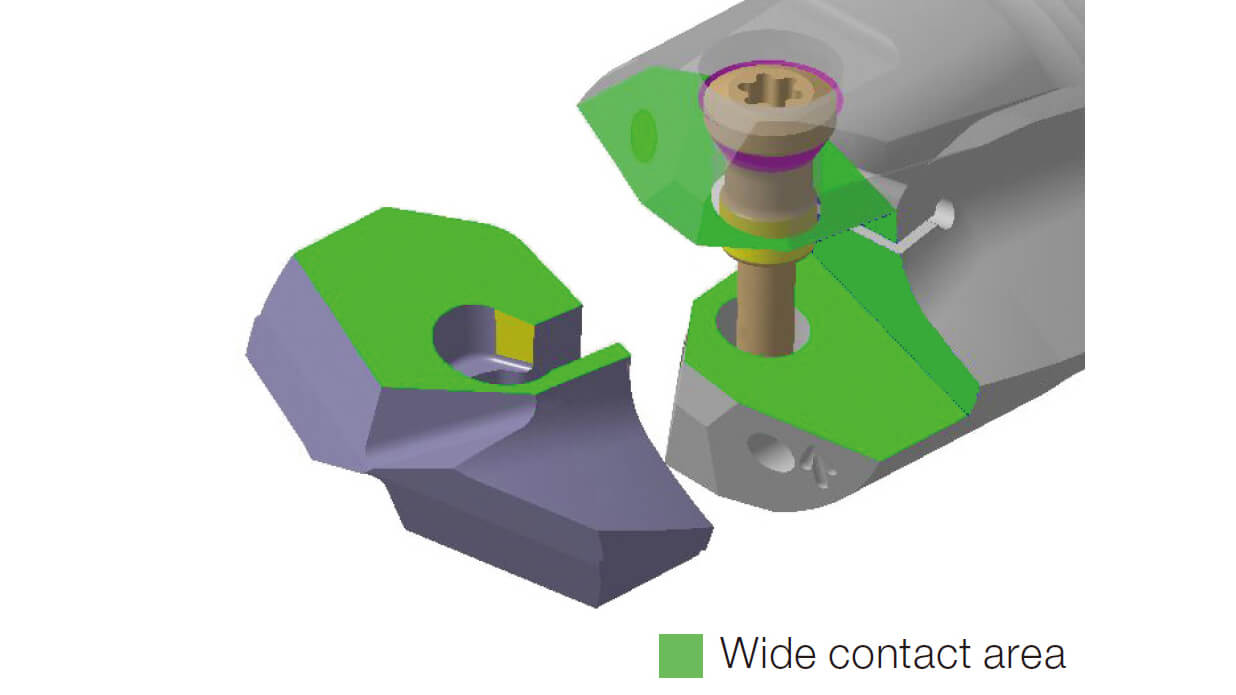

DrillForce-Meister is a replaceable-head drill specialized for large-diameter hole machining. Featuring a unique clamping mechanism and a dual-edge design, it delivers high hole accuracy and productivity. The easy head replacement also contributes to extended tool life.

Benefits and Features

Feature 1: Achieves high-precision and high-efficiency deep hole machining

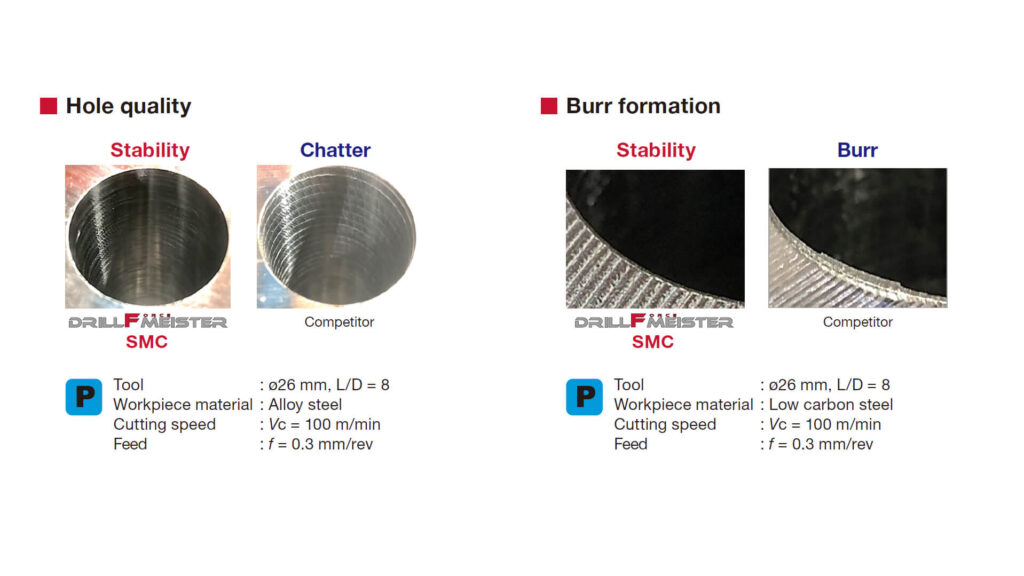

- Enables one-pass deep hole drilling without the need for pilot holes, even with long overhangs up to 8×D

- Improves productivity by reducing lead time and minimizing tool change frequency

- Significantly reduces tooling costs, maximizing cost performance

Feature 2: Combines excellent cutting performance with extended tool life

- Chamfered cutting edge design suppresses chipping during machining and reduces burrs on the machined surface

- Special PVD coating “AH9130” provides superior wear resistance for both steel (P materials) and cast iron (K materials)

- Enables stable long-term machining, extending tool life and reducing replacement frequency

Success Stories

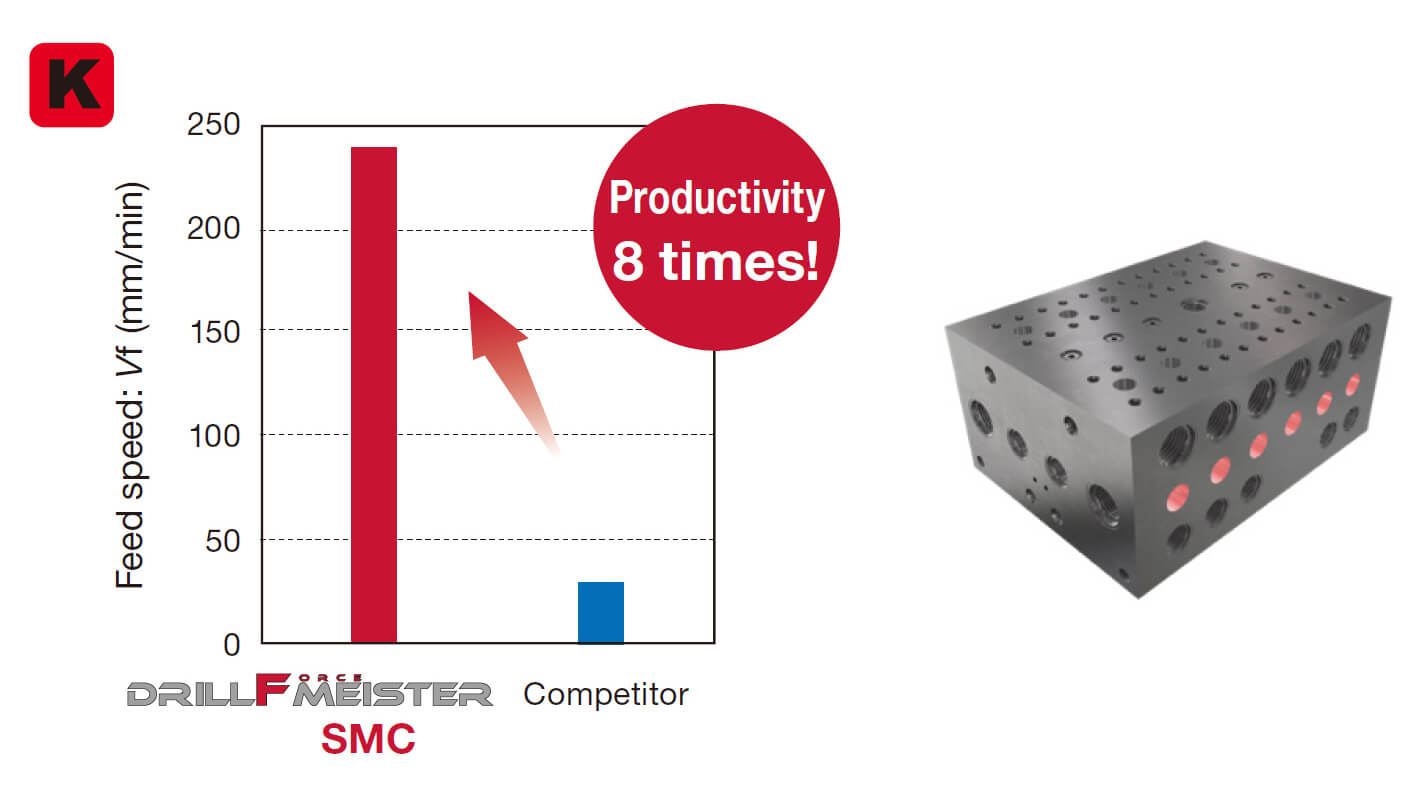

IMPROVED PRODUCTIVITY

DrillForce-Meister achieved 1.9times higher productivity thanks to outstanding entry stability with SMC head and extremely rigid drill design. There were various workpiece shapes and fixtures, but the ability to machine with a long overhang allowed us to unify the tooling.

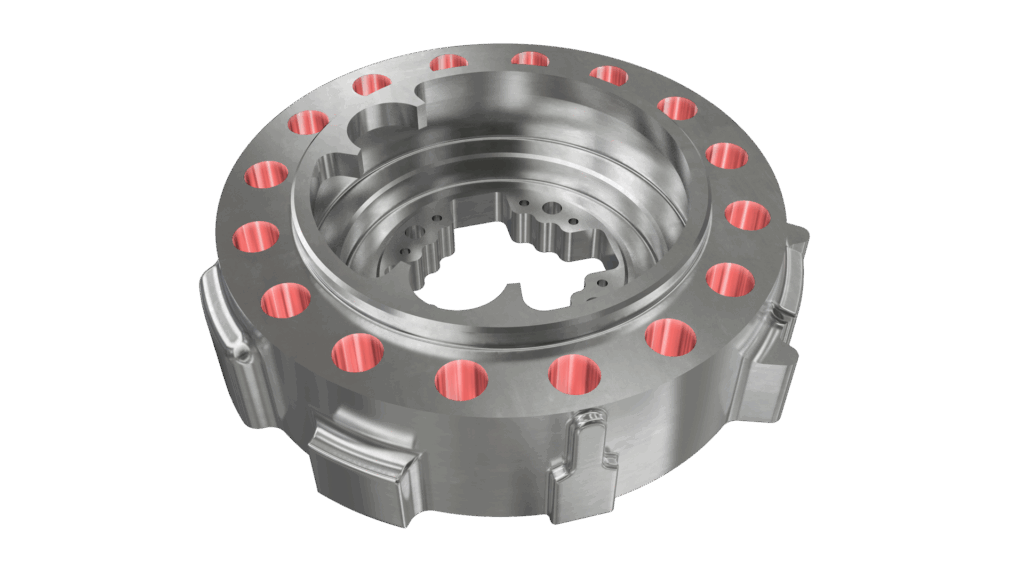

| Industry | Heavy |

| Component | Machine part |

| Material ISO code | K – Cast iron |

| Work material | FCD600/GGG60 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillForce-Meister |

| TSR No. | 5275D |