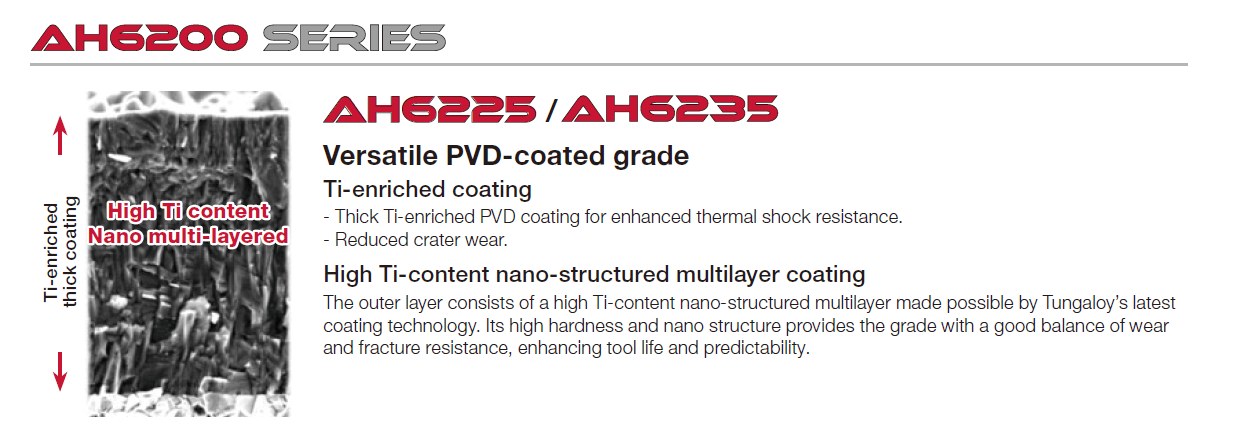

Iwaki, Japan – August, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its T6200 and AH6200 series, adding 53 ISO inserts in the AH6225 grade that deliver superior wear and fracture resistance for stable and efficient stainless steel machining across diverse applications.

Challenges and Trends

In stainless steel machining, where both wear resistance and stability are essential, there is a growing demand for high-performance inserts across a wide range of industries—from general-purpose mechanical components to aerospace, shipbuilding, and automotive sectors. However, with the conventional AH6225 grade, the lack of standard settings for specific chipbreakers has prevented users from obtaining their desired specifications, leading to missed adoption opportunities. To address these Challenges and Market Conditions, an expansion of the product lineup has become necessary.

Product Overview

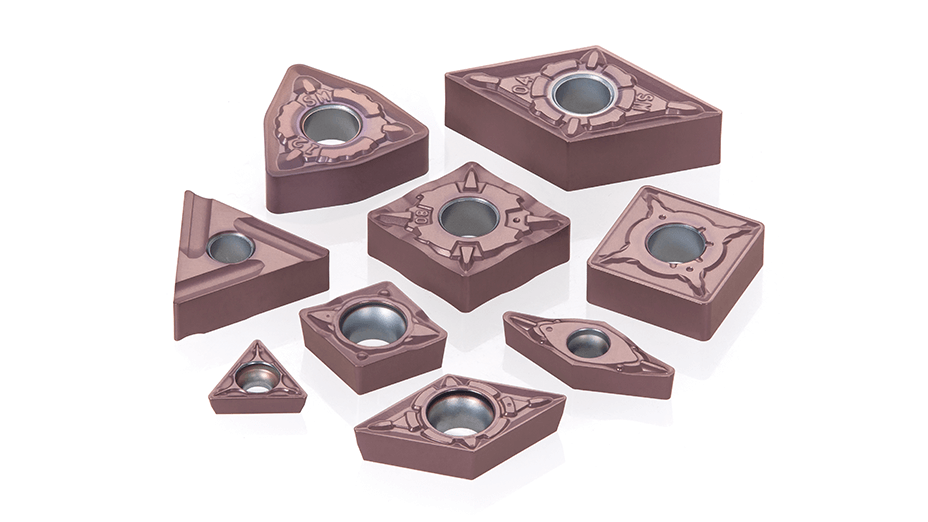

T6200 and AH6200 series are the latest inserts from Tungaloy, specifically designed for turning stainless steel. Featuring wear-resistant coatings and high reliability, they offer excellent performance across a wide range of applications, from continuous to interrupted cutting.

Benefits and Features

Excellent Balance of Wear Resistance and Resistance to Plastic Deformation

– AH6225 features a thick, titanium-rich coating that provides exceptional wear resistance

– The specially designed substrate with high thermal conductivity efficiently disperses heat during cutting, extending tool life

– Enhanced resistance to plastic deformation while maintaining fracture toughness ensures stable performance even under high-load machining conditions

Superior Chip Control Performance for a Wide Range of Machining Conditions

– A wide variety of chipbreaker options supports operations from roughing to finishing

– High chip evacuation performance even with hard-to-cut materials like stainless steel minimizes machining troubles

– Improved chip control enhances both machining stability and productivity

Expanded Application Range Through Availability in ISO Inserts

– AH6225 is now available in various ISO insert shapes, offering greater selection flexibility

– Easily replaces existing tools in current machining processes, reducing implementation costs

– Compatible with a wide range of machines and machining conditions, meeting diverse user needs