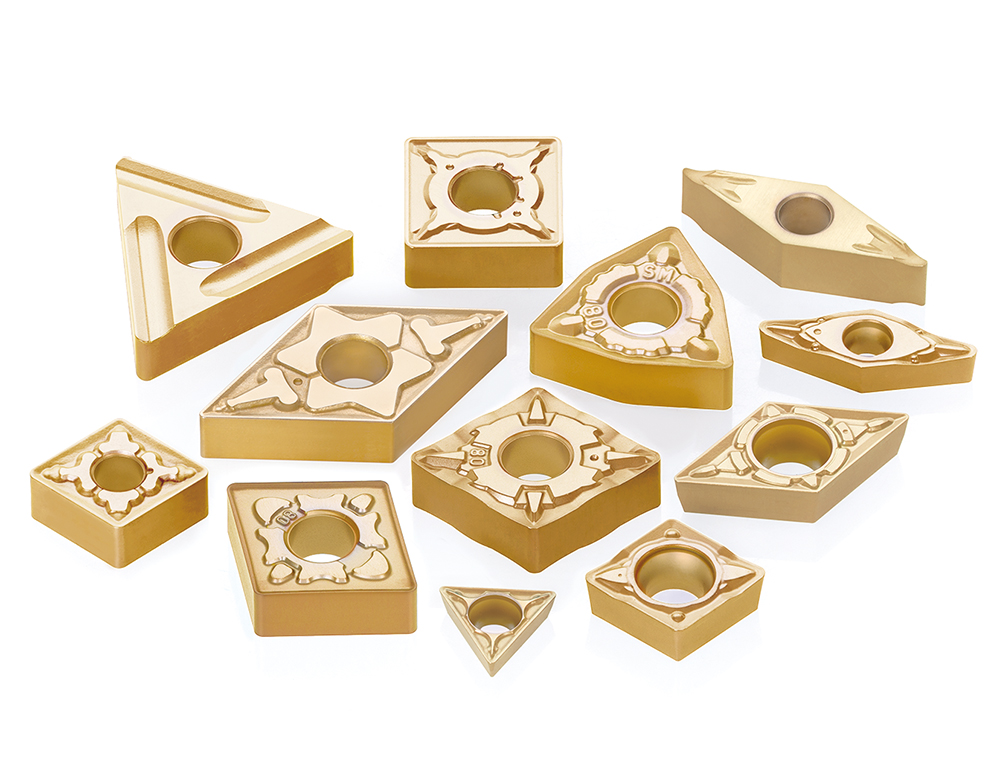

Latest grade series for stainless steel turning with exceptional reliability

Latest grade series that provide solutions for all your machining challenges in stainless steel

Applications & Features

Applications

Features

1. Application range

2. Grade feature

Versatile PVD-coated grade

Ti-enriched coating

– Thick Ti-enriched PVD coating for enhanced thermal shock resistance

– Reduced crater wear

High Ti-content nano-structured multilayer coating

The outer layer consists of a high Ti-content nano-structured multilayer made possible by Tungaloy’s latest coating technology. Its high hardness and nano structure provides the grade with a good balance of wear and fracture resistance, enhancing tool life and predictability.

Dedicated carbide substrate

Thanks to high thermal conductivity of the substrate, heat generated during machining is dissipated, efficiently reducing temperature on the cutting edge. This provides edge toughness, while reducing plastic deformation of the cutting edge. Ideal for continuous cuts.

AH6235 incorporates a tough substrate that provides process security during interrupted machining. This tough substrate provides the grade with added reliability during interrupted cuts.

Superior wear resistance

Enhanced hardness of outer layer

– Hard outer layer coating significantly reduces flank wear.

Strong adhesion of Al2O3 layers

– Tungaloy’s latest Al2O3 coating technology enhances the grade’s adhesion of coating, preventing edge chipping and coating delamination.

Thick coating

– 30% thicker than conventional grades.

– Provides superior wear resistance and long tool life.

Grades

T6215

![]()

![]()

-

P10 – P30 / M10 – M30

- Demonstrates excellent wear resistance for high speed continuous stainless steel cuts

AH6225

![]()

![]()

- P20 – P30 / M20 – M30

- First choice for stainless steel

- Excellent versatility for stainless steel machining, demonstrates a good combination of wear and fracture resistance

AH6235

![]()

![]()

- P30 – P40 / M30 – M40

- Demonstrates superior fracture resistance in stainless steel

- Provides high reliability for interrupted cuts and heavy-duty machining

Practical examples

Example #1

| Part: | Pipe part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | DNMG150408-SM |

| Grade: | T6215 |

| Cutting conditions: | Vc = 150(m/min) f = 0.3 (mm/rev) ap = 3 (mm) Application: External turning Coolant: Wet |

Example #2

| Part: | Machine part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | TNMG160408-SM |

| Grade: | T6215 |

| Cutting conditions: | Vc = 200(m/min) f = 0.3 (mm/rev) ap = 2.5 (mm) Application: External face turning Coolant: Wet |

Example #3

| Part: | Generator part |

| Material: | SUS410 / X12Cr13 |

| Insert: | CNMG120408-SH |

| Grade: | AH6235 |

| Cutting conditions: | Vc = 70 (m/min) f = 0.15 (mm/rev) ap = 2 – 4 (mm) Application: Face turning (interrupted cutting) Coolant: Wet |

Example #4

| Part: | Machine part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | CNMG120412-SM |

| Grade: | AH6235 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.2 (mm/rev) ap = 1.5 (mm) Application: Face turning (interrupted cutting) Coolant: Wet |

Example #5

| Part: | Joint part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | CNMG120404-SM |

| Grade: | AH6225 |

| Cutting conditions: | Vc = 90(m/min) f = 0.2 (mm/rev) ap = 1 (mm) Application: External turning Coolant: Wet |

Example #6

| Part: | Machine part |

| Material: | SUS440 (Martensite stainless steel) |

| Insert: | VNMG160404-SF |

| Grade: | AH6225 |

| Cutting conditions: | Vc = 110 (m/min) f = 0.1 (mm/rev) ap = 0.5 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

Negative inserts

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Austenitic stainless steel |

Ferritic / martensite stainless steel |

Precipitation hardened stainless steel |

||||||

|

Finishing | SF | T6215 | 0.5 – 2.5 | 0.08 – 0.45 | 140 – 240 | 160 – 280 | 80 – 150 |

| AH6225 | 0.5 – 2.5 | 0.08 – 0.45 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.5 – 2.5 | 0.08 – 0.45 | 50 – 150 | 70 – 170 | – | |||

| Medium cutting | SM | T6215 | 1 – 4 | 0.2 – 0.5 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 1 – 4 | 0.2 – 0.5 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 4 | 0.2 – 0.5 | 50 – 150 | 70 – 170 | – | |||

| SDM | T6215 | 1 – 4 | 0.2 – 0.5 | 140 – 240 | 160 – 280 | 80 – 150 | ||

| AH6225 | 1 – 4 | 0.2 – 0.5 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 4 | 0.2 – 0.5 | 50 – 150 | 70 – 170 | – | |||

| Heavy cutting | SH | T6215 | 2 – 6 | 0.3 – 0.6 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 2 – 6 | 0.3 – 0.6 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 2 – 6 | 0.3 – 0.6 | 50 – 150 | 70 – 170 | – | |||

Positive inserts

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Austenitic stainless steel |

Ferritic / martensite stainless steel | Precipitation hardened stainless steel | ||||||

|

Finishing | PSS | T6215 | 0.3 – 2 | 0.08 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 |

| AH6225 | 0.3 – 2 | 0.08 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.3 – 2 | 0.08 – 0.3 | 50 – 150 | 70 – 170 | – | |||

| Finishing to medium cutting |

PS | T6215 | 0.5 – 2.5 | 0.08 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.5 – 2.5 | 0.08 – 0.3 | 50 – 150 | 70 – 170 | – | |||

| Medium cutting | PM | T6215 | 1 – 3 | 0.15 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 1 – 3 | 0.15 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 3 | 0.15 – 0.3 | 50 – 150 | 70 – 170 | – | |||

For more information about this product, visit our online e-catalog or download the product report:

Metric

T6200 & AH6200 series

Imperial

AH6225