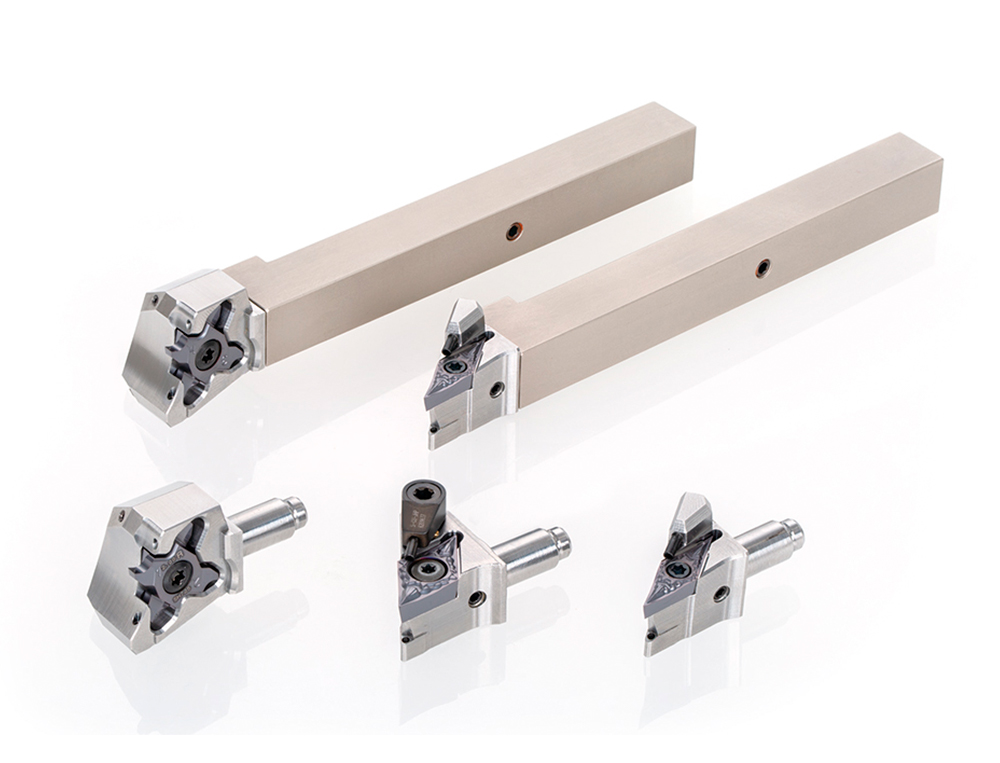

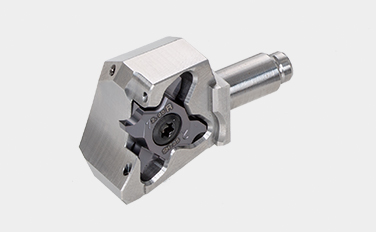

Modular head turning toolholder system for Swiss machines

Significantly reduces machine downtime for changing tools and setups

Applications & Features

Applications

Features

1. Unified cutting head sizes

Designed with common functional lengths (LF), the cutting heads allow easy tool changes without removing the shank from the tool post.

2. High repeatability*

ModuMini-Turn provides the cutting edge point position with high repeatability with an accuracy of ±5 μm or less for the x and z axis.

*Using the same type of head, shank, and insert shape

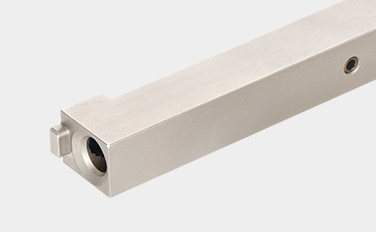

3. Shank size flexibility

Applicable for many types of machines, due to the large variety of shank lengths. The same coupling shape allows shared heads to all types of shanks.

4. Unique coupling design

Simply loosen the clamping screw for easy tool exchanges. Unique coupling design allows extremely high repeatability.

Inserts & Grades

Inserts

Inserts for External Turning

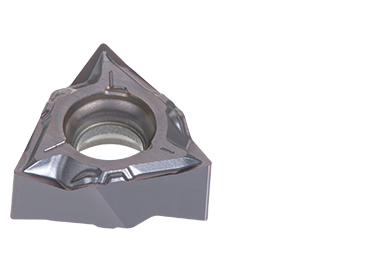

MiniForce-Turn Inserts

- Innovative double-sided positive insert

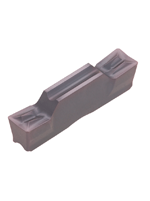

TetraMiniCut Grooving and Parting-off Inserts (Grooving width 0.33 – 3.0 mm)

- Rigid grooving tools with 4 cutting-edge insert

TetraMiniCut Threading Inserts

- Rigid threading tools with 4 cutting-edge insert

TungCut Inserts for Grooving (Grooving width 1.2 – 2.0 mm)

Main Grades

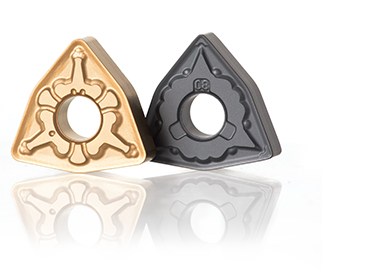

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T515

![]()

- K10 – K20

- Stable machining in a wide range of applications from continuous to interrupted cutting

AH7025

![]()

![]()

![]()

- P20 – P30 / M20 – M30 / S15 – S25

- Excellent wear resistance and high rigidity

- First choice for grooving of various materials

Bodies

For more information about this product, visit our online e-catalog or download the product report: