Deep Hole Drilling with the DeepTri-Drill

Tungaloy’s DeepTri-Drill features a drill body that stays in the machine. As one edge of the carbide insert and guide pads begins to dull, tool changes take less than a minute because all you need to do is index the insert and the guide pad by rotating a new edge forward instead of taking a brazed gundrill out of its machine through the whip guides. That eliminates downtime and saves money.

Tungaloy’s DeepTri-Drill features a drill body that stays in the machine. As one edge of the carbide insert and guide pads begins to dull, tool changes take less than a minute because all you need to do is index the insert and the guide pad by rotating a new edge forward instead of taking a brazed gundrill out of its machine through the whip guides. That eliminates downtime and saves money.

FAQs about Deep Hold Drilling with the DeepTri-Drill

Tungaloy America’s Chief Technical Officer, Kedar Bhagath answers the most frequently asked questions about deep hole drilling and the DeepTri-Drill.

Q. What are the advantages of using the indexable gundrill (DeepTri- Drill) over brazed gundrill?

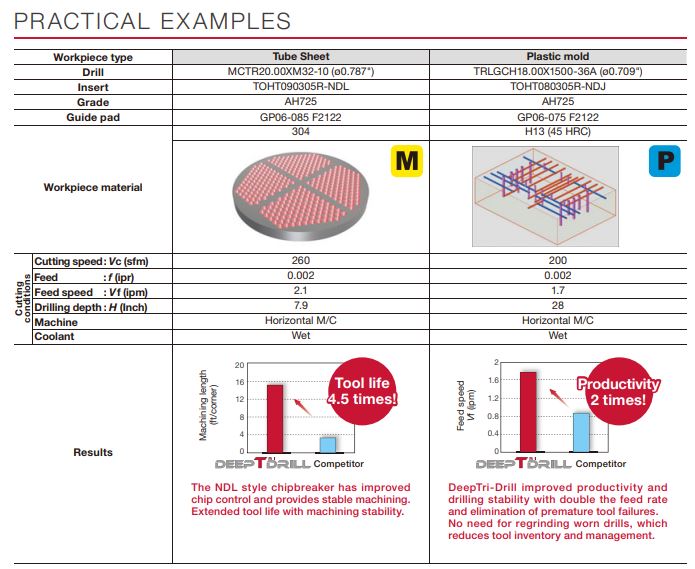

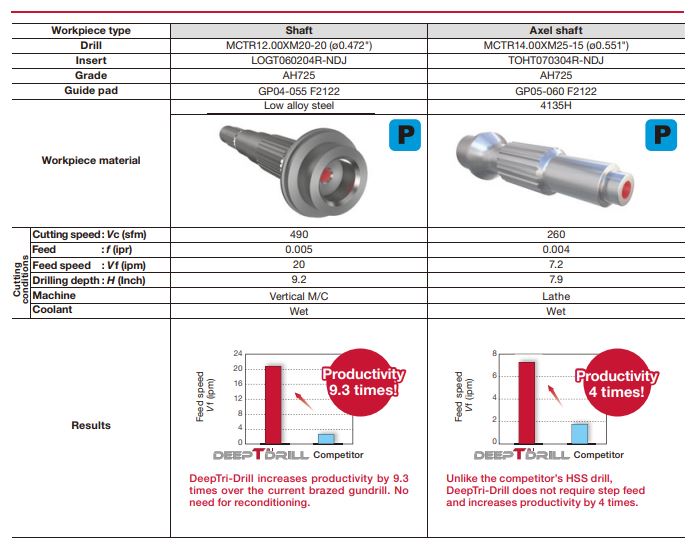

A. Speeds and feeds are at least 2 to 3 times faster than a brazed gundrill. Diameter is adjustable up to 0.1mm (0.004″) for high accuracy and surface finish is considerably better compared to the brazed gundrill.

Q. Why does the DeepTri- Drill run faster when compared to a brazed gundrill?

A. The insert is comprised of a well-engineered chip former and has a new coating technology. In addition, the chip splitter design on the insert creates short chips which are easier to evacuate from deep holes, allowing faster machining at a reduced cutting load.

Q. Which materials can the DeepTri- Drill machine?

A. DeepTri- Drill is an excellent choice for all materials from die steel, stainless steel, super alloys to nonferrous alloys. Apart from improving the productivity and tool life on die steel and nonferrous material, the DeepTri- Drill is especially well suited for stainless steel and super alloy drilling, where the tool life is considerably lower and customers do not need to replace the gundrill on the machine rather just index the insert and guide pad.

Q. How many indexes are available on the DeepTri- Drill.

A. Depending on the insert for the specific diameter, it provides 2 to 3 indexes. And guide pads provide 2 indexes.

Q. Can deep hole drilling be performed on a regular milling machine and/or lathe?

A. Yes, we recommend up to 25 times diameter drilling on the machining center. Some smaller diameters are available up to 45 times diameter for machining center / lathe drilling.

Q. What are the basic requirements to use the DeepTri- Drill on a machining center / lathe?

A. You’ll need a precise pilot hole prior to using the DeepTri-Drill on the machine. The pilot hole acts like a guide bush and the guide pads on the tool support the drill to achieve a straight hole and good surface finish.

If you have questions on the DeepTri-Drill contact Kedar Bhagath at [email protected].

For specs and product information on the DeepTri-Drill >

|

Video Player 00:00

01:45

|

|

|

|

|

| Buy this product from the webshop > |