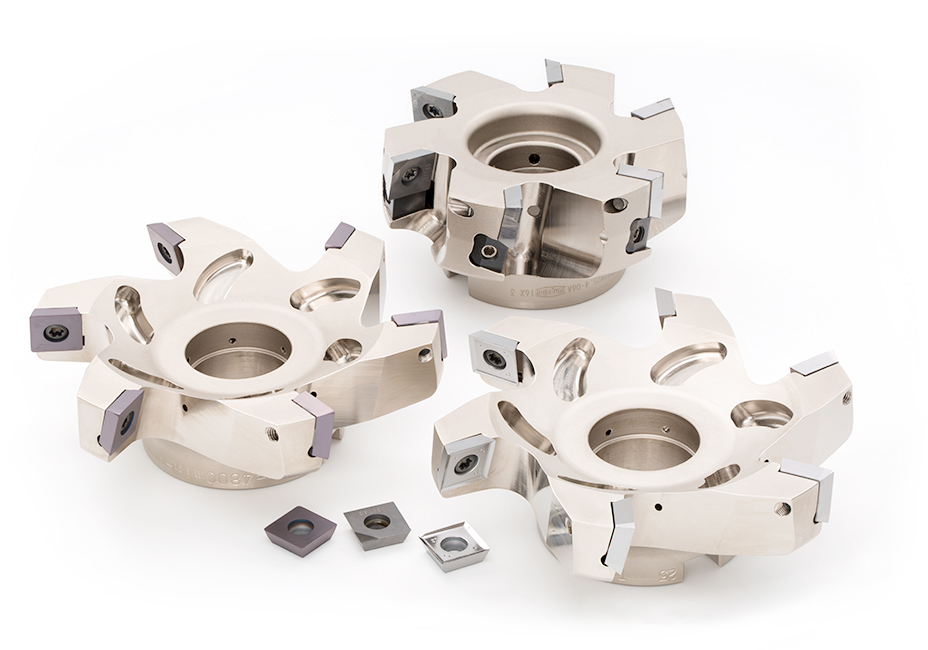

High precision face milling series with lightweight and adjustable pocket bodies

Extremely lightweight facemill series now integrates adjustable pockets for an extra precision on the surface finish

Applications & Features

Applications

Features

1. Insert density variations

Insert pitch variations allow the best possible tool to be selected for maximum economy in the milling process.

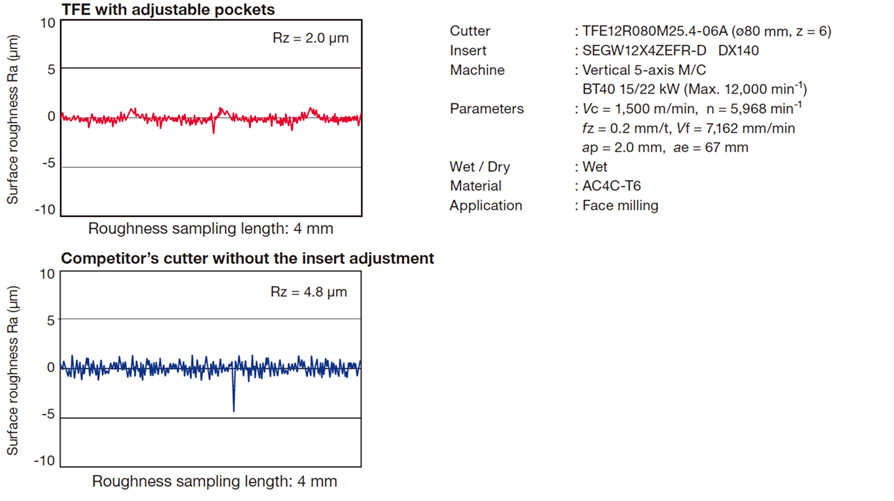

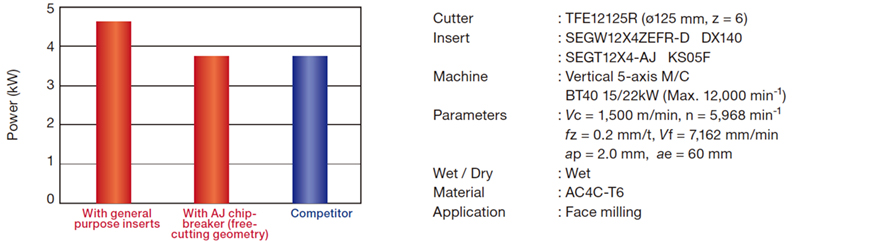

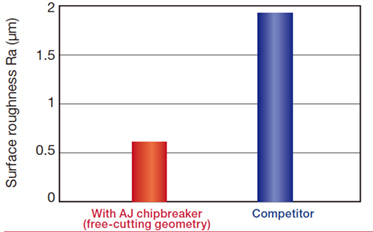

2. Cutting performance (Non-ferrous materials)

Surface roughness

Power requirement – AJ breaker

Surface finish quality – AJ breaker

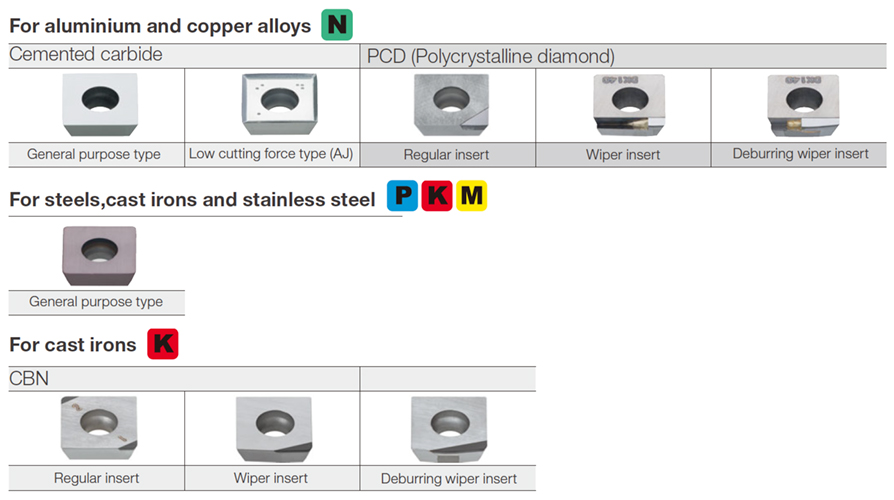

Inserts & Grades

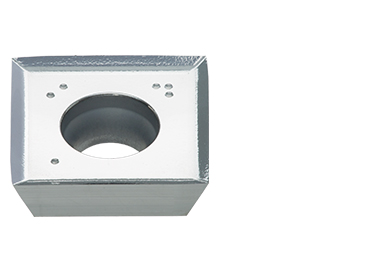

Inserts

Main Grades

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

DX140

![]()

- High wear resistance

- Designed for non-ferrous metal and nonmetal

BX480

![]() Sintered metal

Sintered metal

- Hardest T-CBN

- Ideal for ferrous sintered metal

- Suitable for high-speed face milling of cast iron

Cutter bodies

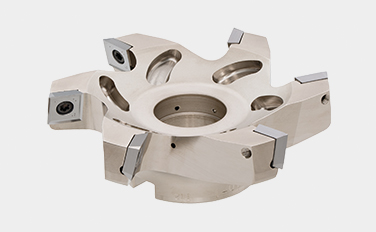

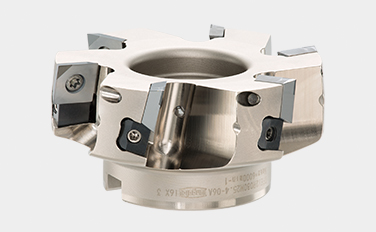

Bore Type

TFE12R (ø63 – 125 mm)

85.5° face mills with screw clamped inserts for aluminum machining

Bore Type with adjustable pockets

TFE12R-A (ø80 – ø125 mm)

85.5° face mills for aluminum machining, with screw clamped inserts and adjustable pockets for axial runout

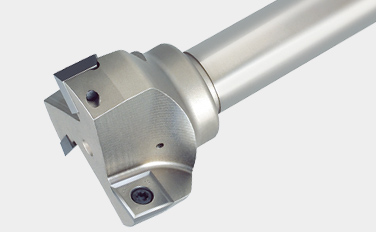

Shank Type

EFE12R (ø50 mm)

85.5° endmills with screw clamped inserts for aluminum machining

Practical examples

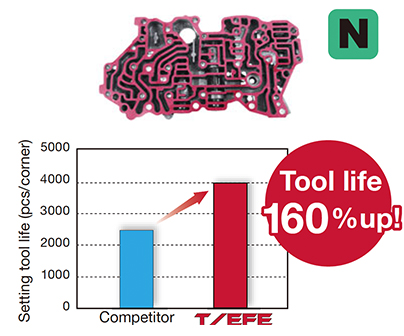

Example #1

Automotive Industry

| Part: | Valve body |

| Material: | ADC12 |

| Cutter: | TFE12R125M31.7-10A (.125 mm, z = 10) |

| Insert: | SEGW12X4ZEFR-D |

| Grade: | ADC12 |

| Cutting conditions: | Vc = 2,000 (m/min) fz = 0.06 (mm/t) Vf = 2,400 (mm/min) ap = 0.5 (mm) ae = 100 (mm) Application: Face milling Coolant: Wet Machine: Vertical M/C,BT40 |

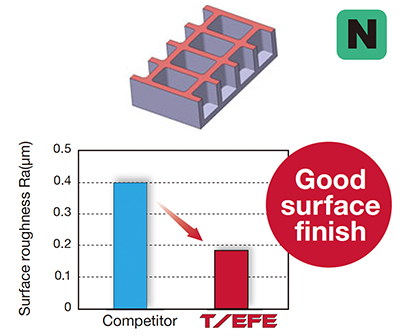

Example #2

General Engineering

| Part: | Plate |

| Material: | AC4C-T6 |

| Cutter: | TFE12R080M25.4-06A (.80 mm, z = 6) |

| Insert: | SEGW12X4ZEFR-D |

| Grade: | DX140 |

| Cutting conditions: | Vc = 1,500 (m/min) fz = 0.2 (mm/t) Vf = 7,200 (mm/min) ap = 2.0 (mm) ae = 60 (mm) Application: Face milling Coolant: Wet Machine: Vertical M/C、BT40 |

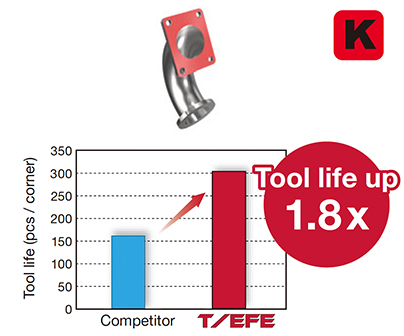

Example #3

General Engineering

| Part: | Pipe exhaust |

| Material: | FCD500 |

| Cutter: | TFE12R125M31.7-10A (.125 mm, z = 10) |

| Insert: | 2QP-SECW12X412ZETR |

| Grade: | FCD500 |

| Cutting conditions: | Vc = 800 (m/min) fz = 0.02 (mm/t) Vf = 407 (mm/min) ap = 0.4 (mm) ae = 90 (mm) Application: Face milling / Interrupted Coolant: Wet Machine: Vertical MC |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Grade | Designation | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|

| Carbon steels and alloy steels | < 300HB | AH120 | SEGW12X4ZEPR | 100 – 180 | 0.03 – 0.15 | |

| < 300HB | NS740 | SEGW12X4ZEPR | 100 – 180 | 0.03 – 0.15 | ||

| Stainless steels | < 250HB | AH140 | SEGW12X4ZEPR | 80 – 180 | 0.03 – 0.15 | |

| Grey and ductile cast irons | 150 – 250 HB | AH120 | SEGW12X4ZEPR | 100 – 200 | 0.03 – 0.15 | |

| Grey cast iron | 150 – 250 HB | BX480 | 2QP-SECW12X412ZETR | 800 – 1500 | 0.05 – 0.3 | |

| Ductile cast irons | 150 – 250 HB | BX480 | 2QP-SECW12X412ZETR | 500 – 800 | 0.05 – 0.2 | |

| Cast aluminium alloy / Die-cast Si < 13% |

– | DS2005, KS05F | SEGT12X4ZEFR-AJ | 200 – 1500 | 0.05 – 0.2 | |

| – | DX140 | SEGW12X4ZEFR-D | 200 – 1500 | 0.05 – 0.2 | ||

| Cast aluminium alloy / Die-cast Si ≥ 13% |

– | DS2005, KS05F | SEGT12X4ZEFR-AJ | 80 – 200 | 0.05 – 0.2 | |

| – | DX140 | SEGW12X4ZEFR-D | 200 – 500 | 0.05 – 0.2 | ||

| Aluminium alloy Tensile strength < 350 N/mm2 |

– | DS2005, KS05F | SEGT12X4ZEFR-AJ | 200 – 1500 | 0.05 – 0.2 | |

| – | DX140 | SEGW12X4ZEFR-D | 200 – 1500 | 0.05 – 0.2 | ||

| Aluminium alloy Tensile strength > 350 N/mm2 |

– | DS2005, KS05F | SEGW12X4ZEFR | 200 – 1500 | 0.05 – 0.2 | |

| – | DX140 | SEGW12X4ZEFR-D | 200 – 1500 | 0.05 – 0.2 | ||

| Copper alloy | – | DS2005, KS05F | SEGT12X4ZEFR-AJ | 200 – 500 | 0.05 – 0.2 | |

| – | DX140 | SEGW12X4ZEFR-D | 200 – 500 | 0.05 – 0.2 |

Notes:

- In milling aluminium and copper alloys:

- For improved surface finish, use together with wiper insert SEGW12X4ZEFR-WD

- For reducing burr occurrence, use together with deburring inserts SEGW12X4ZEFR-BD

- When milling aluminium and copper alloys, use of a water soluble cutting fluid is recommended. When milling steels, cast irons, and stainless steels, dry cutting is recommended.

- When the length-to-diameter overhang ratio of the tool (L/D) exceeds 3, reduce cutting speed and feed to 70 to 80% of the values given in the table.

For more information about this product, visit our online e-catalog or download the product report: