Economical 8 edged inserts with light cutting face milling cutter

Light cutting & optimal chip forming insert featuring 8 cutting edges with high positive rake angle

Applications & Features

Applications

Features

1. High positive rake face mill

• Inserts with a high positive rake provide light cutting actions.

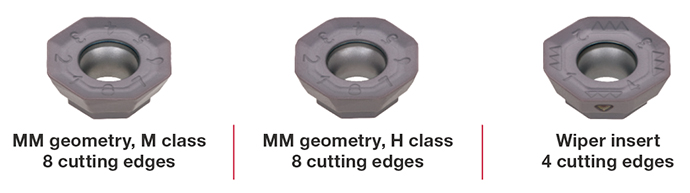

2. Three types of inserts are available

3. Designed to ensure machining stability

• Ideal chip forming.

• Better insert reliability with double flank relief.

Inserts & Grades

Inserts

Grades

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Cutter bodies

Practical examples

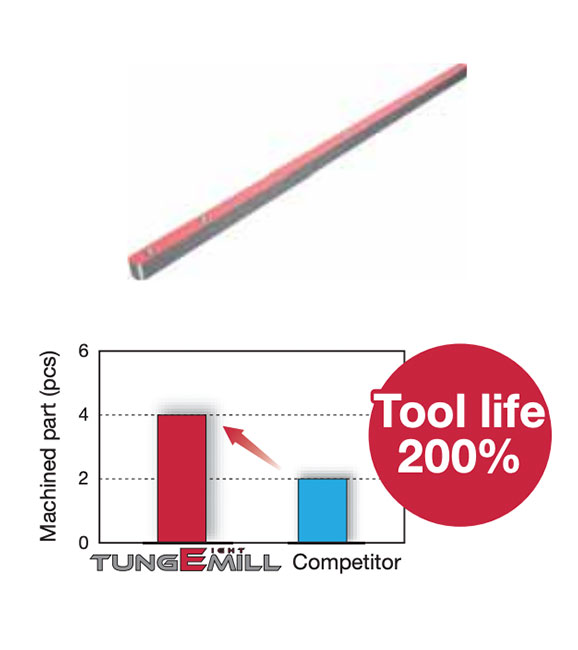

Example #1

General Engineering

| Part: | Part for semiconductor equipment |

| Material: | EN 1.4301 |

| Cutter: | TAOW05M063B22.0R05 |

| Insert: | OWHT05T3C07AFER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 160 (m/min) fz = 0.2 (mm/t) Vf = 808 (mm/min) ap = 1.6 (mm) ae = 19 (mm) Application: Face Milling Coolant: External supply Machine: Vertical M/C (BT40) |

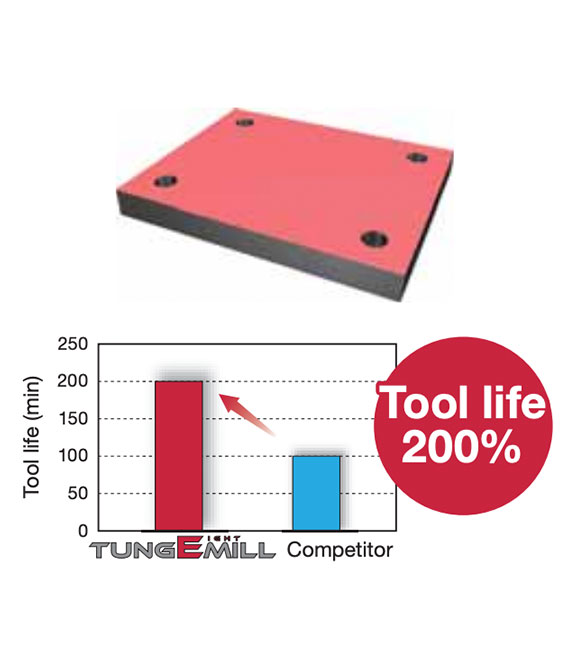

Example #2

General Engineering

| Part: | Base |

| Material: | ISO E275A |

| Cutter: | TAOW05J100B31.7R06 |

| Insert: | OWHT05T3C07AFER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 220 (m/min) fz = 0.2 (mm/t) Vf = 840 (mm/min) ap = 2 (mm) ae = 100 (mm) Application: Face Milling Coolant: External supply Machine: Vertical M/C |

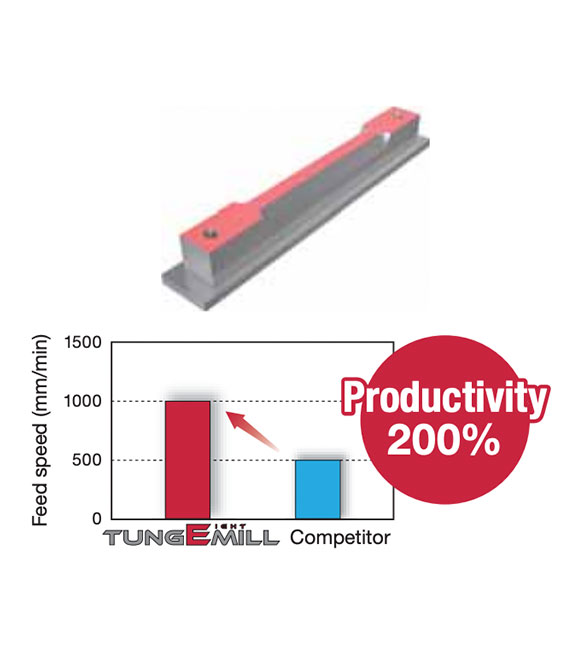

Example #3

General Engineering

| Part: | Machine part |

| Material: | EN 1.7225 |

| Cutter: | TAOW05M063B22.0R05 |

| Insert: | OWMT05T3AFER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.26 (mm/t) Vf = 1000 (mm/min) ap = 2.6 (mm) ae = 18 (mm) Application: Face Milling Coolant: Internal supply Machine: Vertical M/C (BT40) |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Priority | Grade | Chip-breaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steel (C15, etc.) |

– 200HB | First choice | AH3135 | MM | 100 – 300 | 0.05 – 0.35 | |

| Wear resistance | AH120 | MM | 100 – 300 | 0.05 – 0.35 | |||

| High carbon and alloy steel (S55C / C55, SCM440 / 42CrMo4, etc.) |

– 300HB | First choice | AH3135 | MM | 100 – 250 | 0.05 – 0.3 | |

| Wear resistance | AH120 | MM | 100 – 250 | 0.05 – 0.3 | |||

| Prehardened steel (NAK80, PX5, etc.) |

30 – 40 HRC | First choice | AH3135 | MM | 80 – 200 | 0.05 – 0.3 | |

| Wear resistance | AH120 | MM | 80 – 200 | 0.05 – 0.3 | |||

| Austenitic stainless steel (SUS304 / 1.4301, SUS316 / 1.4401, etc.) |

– 200HB | First choice | AH3135 | MM | 100 – 200 | 0.05 – 0.35 | |

| Wear resistance | AH120 | MM | 100 – 200 | 0.05 – 0.35 | |||

| Martensitic stainless steel ( X20Cr13, etc.) |

– 220HB | First choice | AH3135 | MM | 100 – 300 | 0.05 – 0.3 | |

| Wear resistance | AH120 | MM | 100 – 300 | 0.05 – 0.3 | |||

| Gray cast iron (FC250 / 250, etc.) |

150 – 250HB | First choice | AH120 | MM | 100 – 300 | 0.05 – 0.35 | |

| Fracture resistance | AH3135 | MM | 100 – 300 | 0.05 – 0.35 | |||

| Ductile cast iron (FCD400 / 400-15, FCD600 / 600-3, etc.) |

150 – 250HB | First choice | AH120 | MM | 80 – 250 | 0.05 – 0.3 | |

| Fracture resistance | AH3135 | MM | 80 – 250 | 0.05 – 0.3 | |||

| Titanium alloys (Ti-6AI-4V, etc.) |

– | First choice | AH3135 | MM | 30 – 60 | 0.05 – 0.2 | |

| Wear resistance | AH120 | MM | 30 – 60 | 0.05 – 0.2 | |||

| Heat-resistant alloys (Inconel718, etc.) |

– | First choice | AH120 | MM | 20 – 50 | 0.05 – 0.15 | |

| Fracture resistance | AH3135 | MM | 20 – 50 | 0.05 – 0.15 | |||

| Hardened steel (SKD61 / X40CrMoV51, etc.) |

40 – 50HRC | First choice | AH3135 | MM | 70 – 130 | 0.05 – 0.15 | |

| Wear resistance | AH120 | MM | 70 – 130 | 0.05 – 0.15 |

For more information about this product, visit our online e-catalog or download the product report: