Iwaki, Japan – April, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungTap high-performance HSS tap series, offering a wide variety of geometries and coatings to ensure stable, precise threading across diverse materials and applications.

Challenges and Trends

In various industries such as automotive, energy, mold and die, and general manufacturing, threading operations must accommodate a wide variety of materials. Especially in production environments that prioritize high-speed machining and operational simplicity, tools that offer ease of use and stable performance are in high demand. As a result, there is a growing need for high-quality HSS taps that combine reliable cutting performance with user-friendliness. Efficient and dependable threading has become a crucial requirement across many manufacturing settings.

Product Overview

TungTap is a high-performance HSS tap suitable for a wide range of materials, including carbon steel, stainless steel, and difficult-to-cut materials.

It combines high durability with excellent cutting performance, ensuring stable tapping even under demanding machining conditions such as CNC operations.

Benefits and Features

Feature 1: High Versatility Through Optimized Cutting Edge Geometry

The cutting edge geometry has been optimized to accommodate a wide range of work materials

Delivers stable machining performance on materials such as carbon steel, stainless steel, and aluminum alloys

A single tap can handle multiple applications, contributing to improved tool management and cost reduction

Feature 2: Wide Range of Materials and Coating Options

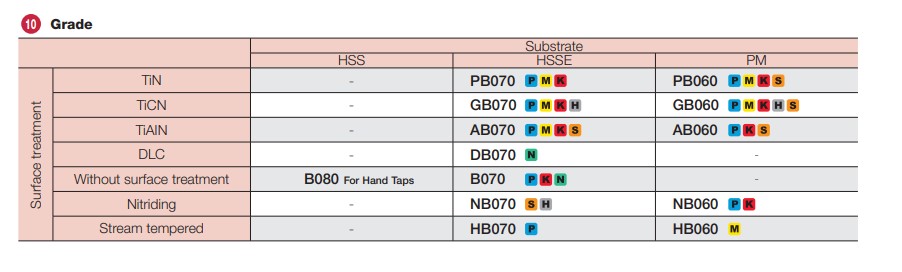

Available in three HSS grades and six coating variations

Enables selection of the best combination based on work material and machining conditions

Offers excellent wear and heat resistance, ensuring long tool life and high-precision thread cutting

Feature 3: Highly Visible Color Band Identification

Color-coded shank allows for quick identification of recommended work materials

Prevents tool selection errors and improves on-site work efficiency

User-friendly design suitable for both beginners and experienced operators