Iwaki, Japan – June, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungMeister series with the addition of high-rigidity shanks and taper neck shanks, enhancing machining stability, reducing tool interference, and increasing productivity in mass production environments.

Challenges and Trends

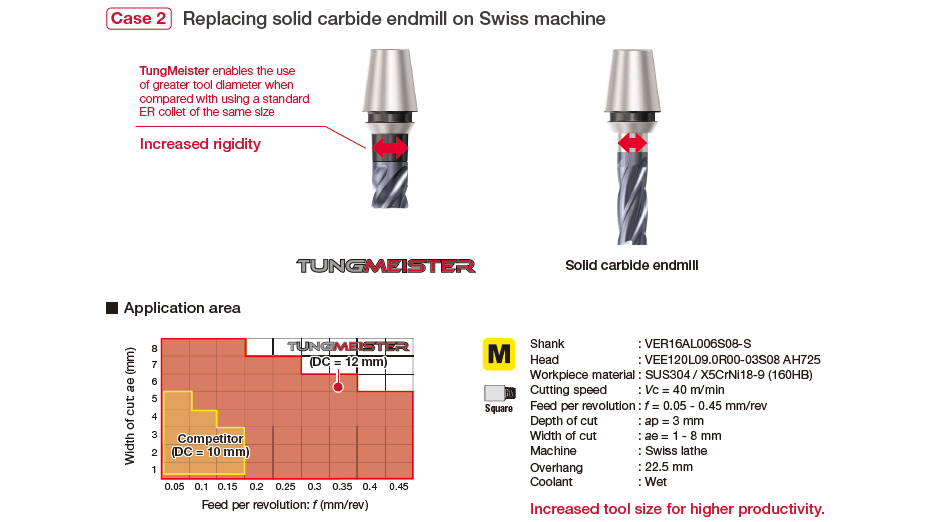

In a wide range of industries such as automotive, construction machinery, general machinery, power generation components, and mold manufacturing, high machining efficiency is required in mass production. However, with conventional solid end mills and exchangeable head end mills, it has often been difficult to ensure sufficient rigidity for the necessary overhang length, resulting in the need to lower cutting conditions. Therefore, securing tool rigidity and achieving high-efficiency machining remain critical issues.

Product Overview

High-Efficiency Exchangeable-Head End Mill

TungMeister is a high-efficiency end mill series with exchangeable heads. With over 13,000 possible combinations, it accommodates a wide range of machining applications. Its easy head replacement enhances operational efficiency and boosts overall productivity.

Benefits and Features

Feature 1: Enhanced Machining Stability with High-Rigidity Shank

– Enlarged shank diameter significantly increases overall tool rigidity

– Adjustable overhang length allows optimal settings to match machining conditions

– Improved rigidity suppresses chatter, enabling high-efficiency and high-precision machining

Feature 2: Tapered Neck Shank for Interference Avoidance and Rigidity Retention

– Tapered neck design prevents interference with workpieces and fixtures

– Maintains high rigidity even during intricate or deep-area machining

– Supports complex shape processing, offering greater flexibility in tool selection

Feature 3: Head Exchangeable Structure for Reduced Setup Time

– Separates cutting edge and shank, allowing replacement of only the head

– Maintains overhang length during head change, minimizing the need for readjustment

– Reduces machine downtime, contributing to higher productivity and cost savings

Success Stories

IMPROVED TOOL LIFE

The VEH milling head enables a wider cutting width (ae), thanks to its excellent anti-vibration design and high-rigidity ø25 mm shank, thereby reducing the number of passes and improving cycle time.

| Industry | Automotive |

| Component | Rack |

| Material ISO code | |

| Work material | SCM440/42CrMo4 |

| Machine(spindle type) | Vertical Machining Center Middle(#40, HSK63) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | TungMeister |

| TSR No. | 5108M |

IMPROVED TOOL LIFE AND PRODUCTIVITY

Featuring improved chip-welding and fracture resistance, TungMeister’s AH715 eliminated welding and edge fracture. As a result, tool life was increased by 2.7 times over the competitor with excellent tool life stability.

| Industry | Automotive |

| Component | Turbine Housing |

| Material ISO code | M – Stainless steel |

| Work material | WNR 1.4826 |

| Machine(spindle type) | Vertical Machining Center Large(#50, HSK100) |

| Tool family | Milling |

| Tool category | Spot drilling |

| Product name | TungMeister |

| TSR No. | 1571M |