Iwaki, Japan – May, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its ModuMini-Turn series, now featuring a modular drill head and small-diameter internal turning head for faster setups and enhanced versatility in compact Swiss-type automatic lathe environments.

Challenges and Trends

Precision parts manufacturers using automatic lathes often face the challenge of limited tool post space, which restricts the number of drilling and internal turning tools that can be mounted. This issue is particularly pronounced in operations involving small-diameter components, where tool changes frequently require re-centering, leading to extended setup times. Additionally, the risk of machining stoppages due to chip entanglement is high, further reducing production efficiency. These challenges significantly impact machine utilization rates, especially in mass production lines such as those for automotive components.

Product Overview

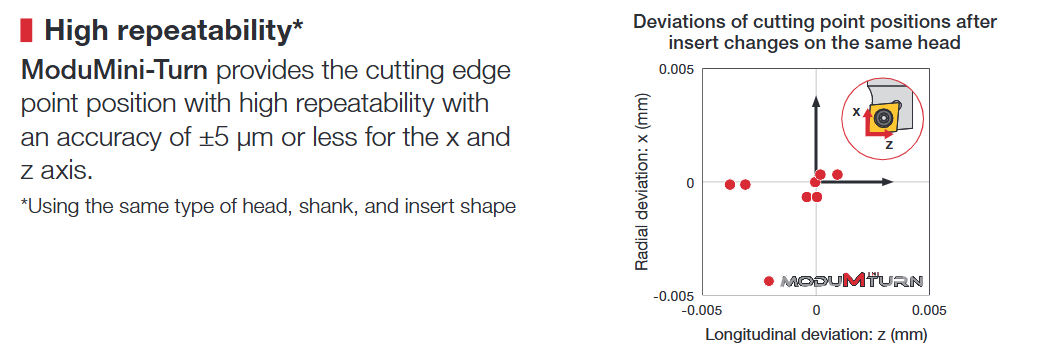

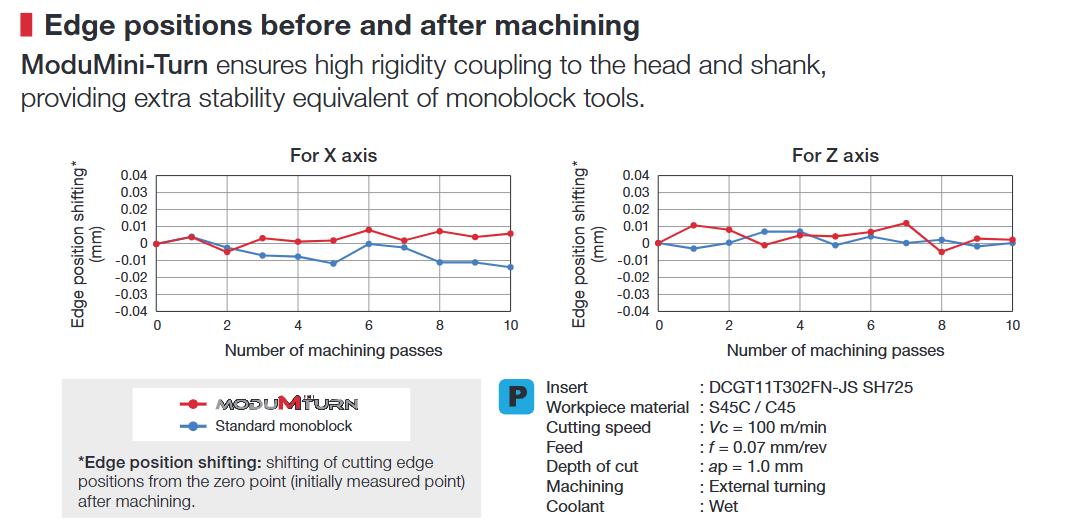

ModuMini-Turn is a high-precision modular turning tool system developed for Swiss-type automatic lathes. Its unique coupling structure ensures a repeatability of ±5 μm, achieving both reduced tool change time and high-precision machining.

Benefits and Features

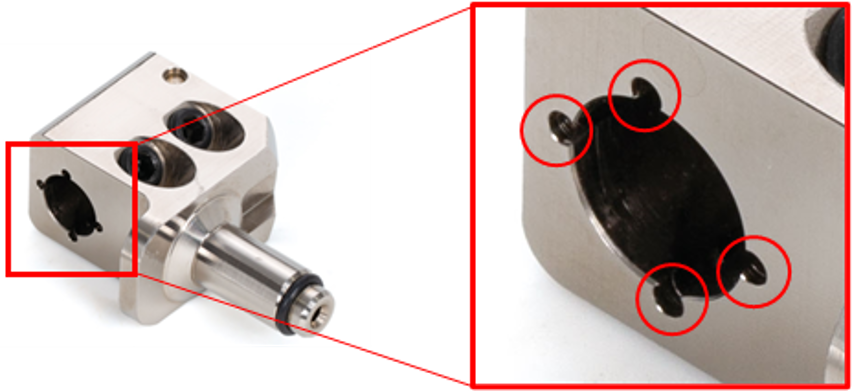

Feature2: High Rigidity and Reliability with Coupling Structure and 4-Way Coolant Supply

・The robust coupling structure minimizes deflection and vibration during machining, ensuring high-precision processing

・The TinyMini-Turn head features four circumferential coolant holes, improving chip evacuation

・Prevents bird nesting, contributing to stable unmanned operation and extended machining cycles

Feature3: Significant Setup Time Reduction with Off-Machine Presetting

・Drill touch-off operations can be completed outside the machine, eliminating the need for on-machine adjustments

・Reduces setup time and maximizes the utilization rate of Swiss-type automatic lathes

・Enables quick and highly repeatable tool changes, minimizing machine downtime