Coated CBN grade for hardened steel

Provides high quality surface on hardened steel parts, when using extremely light depths-of-cut

Applications & Features

Applications

Features

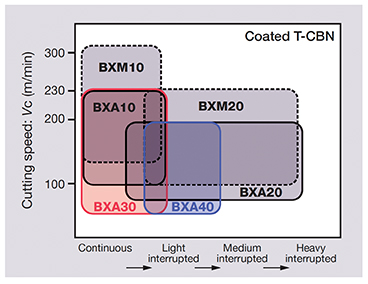

1. Grade properties

- BXA30: Ultra-fine cBN grain uniquely designed for superior adhesion with the PVD coating provides exceptional wear resistance and eliminates built-up edge, delivering excellent surface quality and tool life predictability.

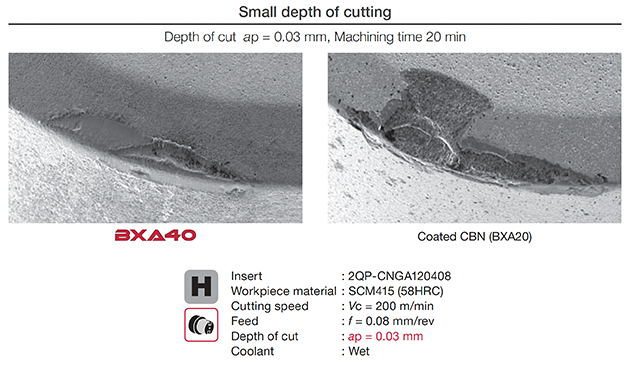

- BXA40: Thanks to the cBN substrate being formulated for superior adhesion with the coating, edge chipping is significantly reduced for extended tool life during interrupted cuts using extremely light depths-of-cut and low feed rates.

2. Application area

Grades

Grades

BXA30

![]()

- Coated CBN grade for high quality surface finishing

BXA40

![]()

- Coated CBN grade ideal of extremely light D.O.C.

Practical examples

Example #1

Automotive Industry

| Part: | Machine parts (Ring) |

| Material: | SCM435H / 34CrMo4 (63HRC) |

| Insert: | 2QP-DCGW11T304 |

| Grade: | BXA30 |

| Cutting conditions: | Vc = 200 (m/min) f = 0.06 (mm/rev) ap = 0.08 (mm) Coolant: Wet |

Example #2

Automotive Industry

| Part: | Bearing parts |

| Material: | SUJ2 / B1 (60HRC) |

| Insert: | 2QP-DCGW11T304 |

| Grade: | BXA30 |

| Cutting conditions: | Vc = 167 (m/min) f = 0.03 (mm/rev) ap = 0.05 (mm) Coolant: Wet |

Example #3

Automotive Industry

| Part: | Sleeve |

| Material: | SCM415H (58HRC) |

| Insert: | 3QP-TPGW110304 |

| Grade: | BXA40 |

| Cutting conditions: | Vc = 120 (m/min) f = 0.1 (mm/rev) ap = 0.03 – 0.05 (mm) Coolant: Wet |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: