Posted at 14:22h

in

[vc_row css_animation="" row_type="row" use_row_as_full_screen_section="no" type="grid" angled_section="no" text_align="left" background_image_as_pattern="without_pattern" z_index=""][vc_column width="3/4"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation="" css=".vc_custom_1593741214043{margin-right: 2% !important;margin-left: 2% !important;}"][vc_column_inner width="1/4"][vc_single_image image="100330" img_size="150x150" style="vc_box_circle_2" qode_css_animation="" el_class="solutions-thumb-img"][/vc_column_inner][vc_column_inner width="3/4"][vc_column_text el_class="product-key-phrase"]

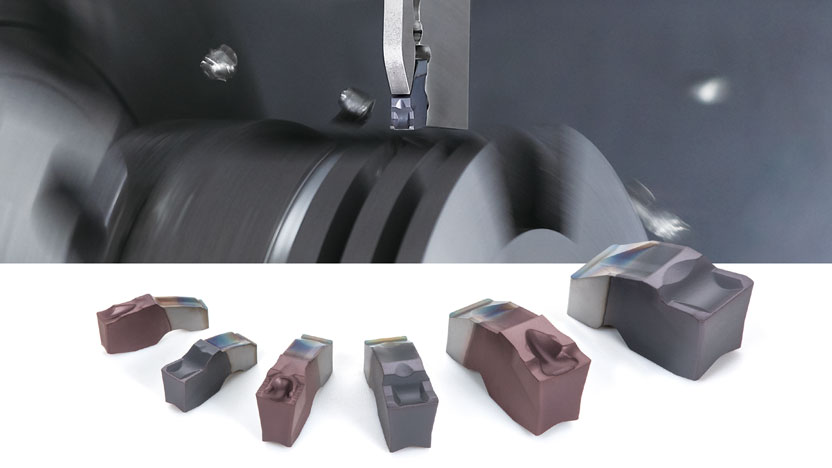

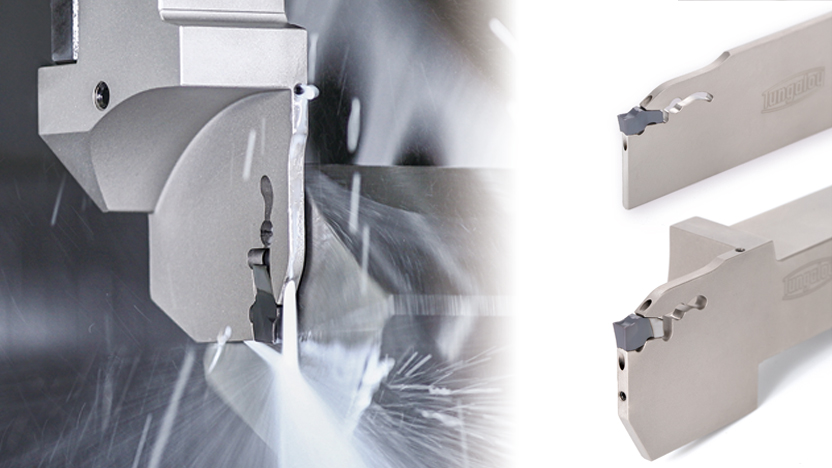

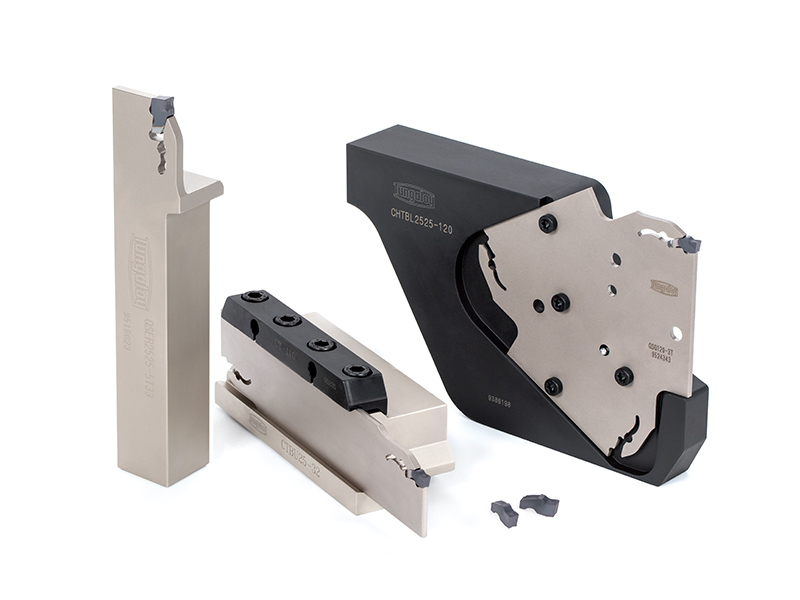

拥有高刚性自锁紧系统的切槽和切断刀具系列

[/vc_column_text][vc_column_text el_class="product-subtitle"]高刚性自锁紧系统提高了切深槽和切断加工的生产效率[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_separator type="transparent" el_class="spacing-50" thickness="0" up="50"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2" css=".vc_custom_1594978887922{margin-bottom: 50px !important;}"][vc_single_image image="100363" img_size="full" qode_css_animation=""][/vc_column_inner][vc_column_inner width="1/2" css=".vc_custom_1594978892320{margin-bottom:...