兼具成本效益與高效能的絲錐,提供可靠的螺紋加工

高品質 HSS 絲錐,適用於多種材料

應用與特點

應用

特點

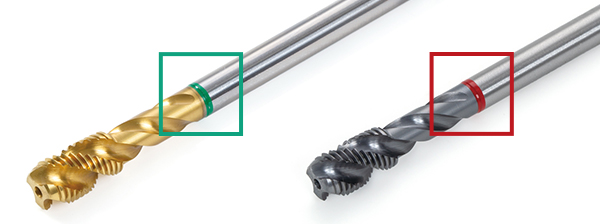

1. 刀柄上的色環可協助您輕鬆辨識絲錐建議的工件材料。

- M-多材料應用

- W-切削性良好的鋼 Rm<750 N/mm2

- S – 不鏽鋼

- H-Hardened steel 與高溫/超合金 Rm>750 N/mm2

- G – 灰口鑄鐵

- N-低合金鋼 Rm<600 N/mm2

- A – 鋁和鋁合金

- F – 伸長率至少為 8~10% 的任何材料

- Y – 鎳合金

絲錐與牌號

絲錐

材質

實際案例

絲錐代號對照表

| 孔類型 | 絲錐色碼 | W | M | M | M | M | M | M | S | H | N | H | G | F | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 工具材料 | 高速鋼 | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | |||||||||||||||||||

| 表面處理/塗層 | – | – | 鈦 | 聖 | – | 鈦 | 聖 | 聖 | – | 聖 | 聖 | 鎳 | 鈦 | |||||||||||||||||||

| 長笛指標和角度 | – | – | – | – | R40° | R40° | R40° | – | – | R40° | R40° | – | – | |||||||||||||||||||

| 鉛符合 DIN 2197 標準 | 1\2\3 | B | B | B | C | C | C | B | B | C | C | C | C | |||||||||||||||||||

| 孔類型 | 1-2-3-4-5 | 4-5 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3-4-5 | 1-2-3-4-5 | |||||||||||||||||||

| 材料 編號 |

材料 | 條件 | 抗拉強度 [N/mm²] |

硬度 HB | 切屑 | 冷卻方式 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | 米/分鐘 | |||||||||||||

| 1 | 非合金鋼和鑄鋼、易切削鋼 | <0.25% 維生素 C | 退火 | 420 | 125 | 延長型 | T | ● | 10-25 | ●● | 15-45 | ● | 8-25 | ●● | 20-25 | ●● | 15-45 | ● | 8-25 | ●● | 20-25 | ●● | 8-25 | ● | 20-25 | ●● | 20-60 | |||||

| 2 | ≥0.25% C | 退火 | 650 | 190 | 中等 | T | ● | 10-20 | ●● | 12-40 | ● | 10-35 | ●● | 15-20 | ●● | 12-40 | ● | 10-35 | ●● | 15-20 | ●● | 10-35 | ●● | 15-20 | ●● | 20-60 | ||||||

| 3 | <0.55% 維生素 C | 淬火和回火 | 850 | 250 | 長 | T | ● | 12-18 | ●● | 15-25 | ● | 6-12 | ●● | 12-18 | ●● | 15-25 | ● | 6-12 | ●● | 12-18 | ●● | 12-18 | ●● | 17-55 | ||||||||

| 4 | ≥0.55% C | 退火 | 750 | 220 | 長 | T | ● | 12-18 | ●● | 15-40 | ● | 6-20 | ●● | 12-18 | ●● | 15-40 | ● | 6-20 | ●● | 12-18 | ●● | 12-18 | ●● | 17-55 | ||||||||

| 7 | 低合金鋼與鑄鋼 (合金元素少於 5%) |

淬火和回火 | 930 | 275 | 長 | X | ● | 10-15 | ●● | 5-25 | ● | 4-10 | ●● | 10-15 | ●● | 5-25 | ● | 4-10 | ●● | 10-15 | ●● | 10-15 | ●● | |||||||||

| 8 | 1000 | 300 | 長 | X | ● | 6-10 | ●● | 5-25 | ● | 4-10 | ●● | 6-10 | ●● | 5-25 | ● | 4-10 | ●● | 6-10 | ●● | 6-10 | ●● | |||||||||||

| 9 | 1200 | 350 | 長 | 一個 | ● | 3-5 | ●● | 5-20 | ● | 3-5 | ●● | 3-5 | ●● | 5-20 | ● | 3-5 | ●● | 3-5 | ●● | 3-5 | ●● | |||||||||||

| 10 | 高合金鋼、鑄鋼和工具鋼 | 退火 | 680 | 200 | 長 | X | ● | 10-15 | ●● | 20-30 | ● | 7-12 | ●● | 10-15 | ●● | 20-30 | ● | 7-12 | ●● | 10-15 | ●● | 10-15 | ●● | 10-30 | ||||||||

| 11 | 淬火和回火 | 1100 | 325 | 長 | X | ● | 7-13 | ●● | 12-25 | ● | 5-10 | ●● | 7-13 | ●● | 12-25 | ● | 5-10 | ●● | 7-13 | ●● | 7-13 | ●● | ||||||||||

| 12 | 不鏽鋼和鑄鋼 | 鐵素體/馬氏體 | 680 | 200 | 中等 | 一個 | ● | 5-9 | ●● | 8-18 | ● | 1-5 | ● | 5-9 | ●● | 2-10 | ● | 1-5 | ●● | 2-10 | ● | 5-9 | ●● | 7-15 | ||||||||

| 13 | 馬氏 體 | 820 | 240 | 長 | 一個 | ● | 4-6 | ●● | 8-15 | ● | 1-5 | ● | 4-6 | ●● | 2-10 | ● | 1-5 | ● | 2-10 | ● | 4-6 | ●● | ||||||||||

| 14 | 不鏽鋼和鑄鋼 | 奧氏體, 雙相鋼 | 600 | 180 | 長 | 一個 | ● | 5-9 | ●● | 8-15 | ● | 1-4 | ● | 5-9 | ●● | 2-10 | ● | 1-4 | ● | 2-10 | ● | 5-9 | ●● | |||||||||

| 15 | 灰口鑄鐵 (GG) | 鐵素體 / 珠光體 | 180 | Ext. Short | X | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 10-30 | ● | ||||||||||

| 16 | 珠光體 / 馬氏體 | 260 | Ext. Short | X | ● | 8-12 | ●● | 10-40 | ●● | 21-31 | ● | 8-12 | ●● | 10-40 | ●● | 21-31 | ● | 8-12 | ●● | 10-30 | ● | |||||||||||

| 17 | 球墨鑄鐵 (GGG) | 鐵 素 體 | 160 | 短 | X | ● | 8-12 | ●● | 10-25 | ●● | 21-31 | ● | 8-12 | ● | 10-25 | ● | 21-31 | ● | 8-12 | ●● | 10-40 | ● | ||||||||||

| 18 | 珠光體 | 250 | Ext. Short | X | ● | 8-12 | ●● | 10-20 | ●● | 21-31 | ● | 8-12 | ●● | 10-20 | ●● | 21-31 | ● | 8-12 | ●● | 10-35 | ● | |||||||||||

| 19 | 可鍛鑄鐵 | 鐵 素 體 | 130 | 短 | X | ● | 10-15 | ● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 15-45 | ●● | 13-20 | ● | 10-15 | ●● | 10-45 | ● | ||||||||||

| 20 | 珠光體 | 230 | 短 | X | ● | 10-15 | ● | 10-40 | ●● | 13-20 | ● | 10-15 | ●● | 10-40 | ●● | 13-20 | ● | 10-15 | ●● | 10-40 | ● | |||||||||||

| 21 | 鋁鍛造合金 | 不可強化 | 60 | 中等 | T | ● | 25-35 | ● | 50-70 | ● | 12-25 | ●● | 25-35 | ● | 30-60 | ● | 12-25 | ●● | 12-25 | ●● | 25-35 | ●● | ||||||||||

| 22 | Hardenable (硬化) | 100 | 中等 | T | ● | 25-35 | ● | 50-70 | ● | 12-25 | ●● | 25-35 | ● | 30-60 | ● | 12-25 | ●● | 12-25 | ●● | 25-35 | ●● | |||||||||||

| 23 | 鑄鋁合金 | ≤12% 矽 | 不可強化 | 75 | 短 | T | ● | 10-15 | ● | 10-40 | ● | 10-25 | ●● | 10-15 | ● | 15-40 | ● | 10-25 | ●● | 10-25 | ●● | 10-15 | ●● | |||||||||

| 24 | Hardenable (硬化) | 90 | 短 | T | ● | 10-15 | ● | 10-40 | ● | 10-25 | ●● | 10-15 | ● | 15-40 | ● | 10-25 | ●● | 10-25 | ●● | 10-15 | ●● | |||||||||||

| 25 | >12% 矽 | 高溫 | 130 | 短 | T | ● | 10-15 | ● | 10-30 | ● | 10-20 | ●● | 10-15 | ● | 15-30 | ● | 10-20 | ●● | 10-20 | ●● | 10-15 | ●● | ||||||||||

| 26 | 銅合金 | >1% 鉛 | 自由切割 | 110 | 中/短 | T | ● | 25-35 | ● | 50-70 | ● | 20-40 | ●● | 25-35 | ● | 30-65 | ● | 20-40 | ●● | 20-40 | ●● | 25-35 | ●● | 17-40 | ||||||||

| 27 | 黃銅 | 90 | 長 | T | ● | 15-20 | ● | 5-60 | ● | 13-30 | ●● | 15-20 | ● | 20-45 | ● | 13-30 | ●● | 13-30 | ●● | 15-20 | ●● | 20-60 | ||||||||||

| 28 | 電解銅 | 100 | 長 | T | ● | 15-20 | ● | 5-25 | ● | 10-17 | ●● | 15-20 | ● | 15-30 | ● | 10-17 | ●● | 10-17 | ●● | 15-20 | ●● | 20-60 | ||||||||||

| 29 | 非金屬 | 硬質塑膠, 纖維塑膠 | 70 邵氏 D | 短 | Z | ● | 6-10 | ● | 5-25 | ● | 6-13 | ●● | 6-10 | ● | 10-20 | ● | 6-13 | ●● | 6-13 | ●● | 6-10 | ●● | ||||||||||

| 31 | 高溫合金 | 鐵基 | 退火 | 200 | 長 | 一個 | ● | 2-4 | ●● | 4-8 | ● | 2-4 | ● | 3-7 | ●● | 2-4 | 2-4 | ● | ||||||||||||||

| 32 | 硬化 | 280 | 長 | 一個 | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 33 | 鎳基或鈷基 | 退火 | 250 | 長 | 一個 | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | ||||||||||||||||

| 34 | 硬化 | 350 | 長 | 一個 | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 35 | 投 | 320 | 長 | 一個 | ● | 2-4 | ●● | 4-8 | ● | 2-4 | 3-7 | ●● | 2-4 | 2-4 | ● | |||||||||||||||||

| 36 | 鈦合金 | 純 | 400 | 190 | 中/短 | 一個 | ● | 6-10 | ●● | 6-10 | ●● | 6-10 | 6-10 | ● | ||||||||||||||||||

| 37 | Alpha+β 合金,硬化 | 1050 | 310 | 中/短 | 一個 | ● | 6-10 | ● | 6-10 | ●● | 6-10 | 6-10 | ● | |||||||||||||||||||

| A-切削油 T-油 X-油或乳化液 Z-乾式或乳化液 |

● 推薦 ●● 適用 |

|||||||||||||||||||||||||||||||

| 孔類型 | 絲錐色碼 | W | M | M | M | M | M | M | S | H | N | H | G | F | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 工具材料 | 高速鋼 | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | 高速鋼-E | |||||||||||||||||||

| 表面處理/塗層 | – | – | 鈦 | 聖 | – | 鈦 | 聖 | 聖 | – | 聖 | 聖 | 鎳 | 鈦 | |||||||||||||||||||

| 長笛指標和角度 | – | – | – | – | R40° | R40° | R40° | – | – | R40° | R40° | – | – | |||||||||||||||||||

| 鉛符合 DIN 2197 標準 | 1\2\3 | B | B | B | C | C | C | B | B | C | C | C | C | |||||||||||||||||||

| 孔類型 | 1-2-3-4-5 | 4-5 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3 | 4-5 | 4-5 | 1-2-3 | 1-2-3 | 1-2-3-4-5 | 1-2-3-4-5 | |||||||||||||||||||

| 材料 編號 |

材料 | 條件 | 抗拉強度 [ksi] |

硬度 HB | 切屑 | 冷卻方式 | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | SFM | |||||||||||||

| 1 | 非合金鋼和鑄鋼、易切削鋼 | <0.25% 維生素 C | 退火 | 61 | 125 | 延長型 | T | ● | 35-80 | ●● | 15-150 | ● | 25-80 | ●● | 65-80 | ●● | 50-150 | ● | 25-80 | ●● | 65-80 | ●● | 25-80 | ● | 65-80 | ●● | 65-195 | |||||

| 2 | ≥0.25% C | 退火 | 94 | 190 | 中等 | T | ● | 35-65 | ●● | 40-130 | ● | 35-115 | ●● | 60-65 | ●● | 40-130 | ● | 35-115 | ●● | 50-65 | ●● | 35-115 | ●● | 50-65 | ●● | 65-195 | ||||||

| 3 | <0.55% 維生素 C | 淬火和回火 | 123 | 250 | 長 | T | ● | 40-60 | ●● | 50-80 | ● | 20-40 | ●● | 40-60 | ●● | 50-80 | ● | 20-40 | ●● | 40-60 | ●● | 40-60 | ●● | 55-180 | ||||||||

| 4 | ≥0.55% C | 退火 | 109 | 220 | 長 | T | ● | 40-60 | ●● | 50-130 | ● | 20-65 | ●● | 40-60 | ●● | 50-130 | ● | 15-35 | ●● | 40-60 | ●● | 40-60 | ●● | 55-180 | ||||||||

| 7 | 低合金鋼與鑄鋼 (合金元素少於 5%) |

淬火和回火 | 135 | 275 | 長 | X | ● | 35-50 | ●● | 15-80 | ● | 15-35 | ●● | 35-50 | ●● | 15-80 | ● | 15-35 | ●● | 35-50 | ●● | 35-50 | ●● | |||||||||

| 8 | 145 | 300 | 長 | X | ● | 20-35 | ●● | 15-80 | ● | 15-35 | ●● | 20-35 | ●● | 15-80 | ● | 15-35 | ●● | 20-35 | ●● | 20-35 | ●● | |||||||||||

| 9 | 174 | 350 | 長 | 一個 | ● | 10-15 | ●● | 15-65 | ● | 10-15 | ●● | 10-15 | ●● | 15-65 | ● | 10-15 | ●● | 10-15 | ●● | 10-15 | ●● | |||||||||||

| 10 | 高合金鋼、鑄鋼和工具鋼 | 退火 | 99 | 200 | 長 | X | ● | 35-50 | ●● | 65-100 | ● | 25-40 | ●● | 35-50 | ●● | 65-100 | ● | 25-40 | ●● | 35-50 | ●● | 35-50 | ●● | 35-100 | ||||||||

| 11 | 淬火和回火 | 160 | 325 | 長 | X | ● | 25-45 | ●● | 40-80 | ● | 15-35 | ●● | 25-45 | ●● | 40-80 | ● | 15-35 | ●● | 25-45 | ●● | 25-45 | ●● | ||||||||||

| 12 | 不鏽鋼和鑄鋼 | 鐵素體/馬氏體 | 99 | 200 | 中等 | 一個 | ● | 15-30 | ●● | 25-60 | ● | 5-15 | ● | 15-30 | ●● | 5-35 | ● | 5-16 | ●● | 5-35 | ● | 15-30 | ●● | 25-50 | ||||||||

| 13 | 馬氏 體 | 119 | 240 | 長 | 一個 | ● | 15-20 | ●● | 25-50 | ● | 5-15 | ● | 15-20 | ●● | 5-35 | ● | 5-16 | ● | 5-35 | ● | 15-20 | ●● | ||||||||||

| 14 | 不鏽鋼和鑄鋼 | 奧氏體, 雙相鋼 | 87 | 180 | 長 | 一個 | ● | 15-30 | ●● | 25-50 | ● | 5-15 | ● | 15-30 | ●● | 5-35 | ● | 5-15 | ● | 5-35 | ● | 15-30 | ●● | |||||||||

| 15 | 灰口鑄鐵 (GG) | 鐵素體 / 珠光體 | 180 | Ext. Short | X | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 35-100 | ● | ||||||||||

| 16 | 珠光體 / 馬氏體 | 260 | Ext. Short | X | ● | 25-40 | ●● | 35-130 | ●● | 70-100 | ● | 25-40 | ●● | 35-130 | ●● | 70-100 | ● | 25-40 | ●● | 35-100 | ● | |||||||||||

| 17 | 球墨鑄鐵 (GGG) | 鐵 素 體 | 160 | 短 | X | ● | 25-40 | ●● | 35-80 | ●● | 70-100 | ● | 25-40 | ● | 35-80 | ● | 70-100 | ● | 25-40 | ●● | 35-130 | ● | ||||||||||

| 18 | 珠光體 | 250 | Ext. Short | X | ● | 25-40 | ●● | 35-65 | ●● | 70-100 | ● | 25-40 | ●● | 35-65 | ●● | 70-100 | ● | 25-40 | ●● | 35-100 | ● | |||||||||||

| 19 | 可鍛鑄鐵 | 鐵 素 體 | 130 | 短 | X | ● | 35-50 | ● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 50-150 | ●● | 45-65 | ● | 35-50 | ●● | 35-150 | ● | ||||||||||

| 20 | 珠光體 | 230 | 短 | X | ● | 35-50 | ● | 35-130 | ●● | 45-65 | ● | 35-50 | ●● | 35-130 | ●● | 45-65 | ● | 35-50 | ●● | 35-130 | ● | |||||||||||

| 21 | 鋁鍛造合金 | 不可強化 | 60 | 中等 | T | ● | 80-115 | ● | 165-230 | ● | 40-80 | ●● | 80-115 | ● | 100-195 | ● | 40-80 | ●● | 40-80 | ●● | 80-115 | ●● | ||||||||||

| 22 | Hardenable (硬化) | 100 | 中等 | T | ● | 80-115 | ● | 165-230 | ● | 40-80 | ●● | 80-115 | ● | 100-195 | ● | 40-80 | ●● | 40-80 | ●● | 80-115 | ●● | |||||||||||

| 23 | 鑄鋁合金 | ≤12% 矽 | 不可強化 | 75 | 短 | T | ● | 35-50 | ● | 35-130 | ● | 35-80 | ●● | 35-50 | ● | 50-130 | ● | 35-80 | ●● | 35-80 | ●● | 35-50 | ●● | |||||||||

| 24 | Hardenable (硬化) | 90 | 短 | T | ● | 35-50 | ● | 35-100 | ● | 35-80 | ●● | 35-50 | ● | 50-130 | ● | 35-80 | ●● | 35-80 | ●● | 35-50 | ●● | |||||||||||

| 25 | >12% 矽 | 高溫 | 130 | 短 | T | ● | 35-50 | ● | 35-100 | ● | 35-65 | ●● | 35-50 | ● | 50-100 | ● | 35-65 | ●● | 35-65 | ●● | 35-50 | ●● | ||||||||||

| 26 | 銅合金 | >1% 鉛 | 自由切割 | 110 | 中/短 | T | ● | 80-115 | ● | 165-230 | ● | 65-130 | ●● | 80-115 | ● | 100-215 | ● | 65-130 | ●● | 65-130 | ●● | 80-115 | ●● | 55-130 | ||||||||

| 27 | 黃銅 | 90 | 長 | T | ● | 50-65 | ● | 15-195 | ● | 45-100 | ●● | 50-65 | ● | 65-150 | ● | 45-100 | ●● | 45-100 | ●● | 50-65 | ●● | 65-195 | ||||||||||

| 28 | 電解銅 | 100 | 長 | T | ● | 50-65 | ● | 15-80 | ● | 35-55 | ●● | 50-65 | ● | 50-100 | ● | 35-55 | ●● | 35-55 | ●● | 50-65 | ●● | 65-195 | ||||||||||

| 29 | 非金屬 | 硬質塑膠, 纖維塑膠 | 70 邵氏 D | 短 | Z | ● | 20-35 | ● | 15-80 | ● | 25-45 | ●● | 20-35 | ● | 35-65 | ● | 20-45 | ●● | 20-45 | ●● | 20-35 | ●● | ||||||||||

| 31 | 高溫合金 | 鐵基 | 退火 | 200 | 長 | 一個 | ● | 5-15 | ●● | 15-25 | ● | 5-15 | ● | 10-25 | ●● | 5-15 | 5-15 | ● | ||||||||||||||

| 32 | 硬化 | 280 | 長 | 一個 | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 33 | 鎳基或鈷基 | 退火 | 250 | 長 | 一個 | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | ||||||||||||||||

| 34 | 硬化 | 350 | 長 | 一個 | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 35 | 投 | 320 | 長 | 一個 | ● | 5-15 | ●● | 15-25 | ● | 5-15 | 10-25 | ●● | 5-15 | 5-15 | ● | |||||||||||||||||

| 36 | 鈦合金 | 純 | 58 | 190 | 中/短 | 一個 | ● | 20-35 | ●● | 20-35 | ●● | 20-35 | 20-35 | ● | ||||||||||||||||||

| 37 | Alpha+β 合金,硬化 | 152 | 310 | 中/短 | 一個 | ● | 20-35 | ● | 20-35 | ●● | 20-35 | 20-35 | ● | |||||||||||||||||||

| A-切削油 T-油 X-油或乳化液 Z-乾式或乳化液 |

● 推薦 ●● 適用 |

|||||||||||||||||||||||||||||||

我可以如何協助您?

您好,我是 Gabby,Tungaloy 的 AI 助理。 我將協助您為螺紋加工應用找到最合適的絲錐。

今天我可以如何協助您?

今天我可以如何協助您?