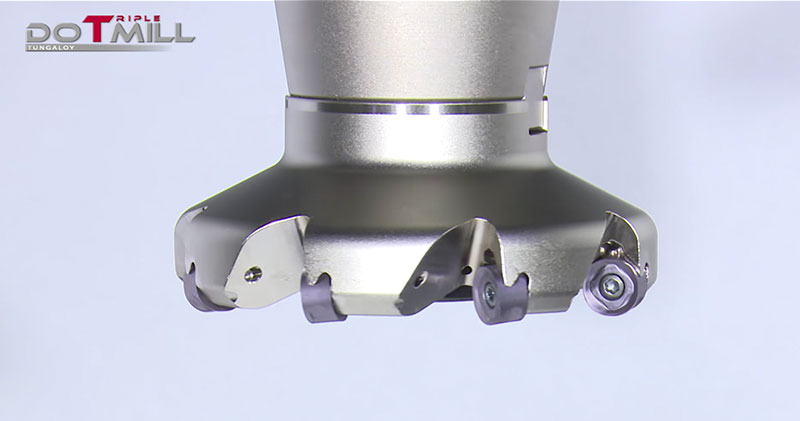

适用于多种材料加工的高通用性面铣刀

DoTriple-Mill 采用改进的燕尾槽锁紧结构并在相同的刀片座上安装四边形。八边形和圆形刀片,实现三倍的优势

应用 & 特点

应用

特点

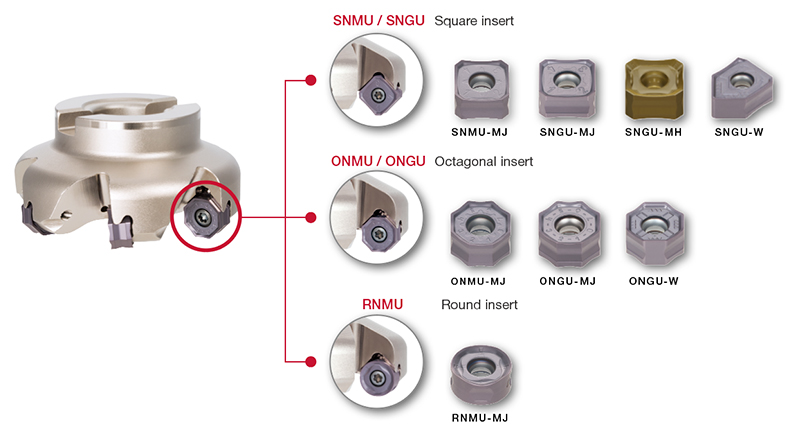

1. 高通用性

• 3种双面刀片可安装在相同的刀片座上。

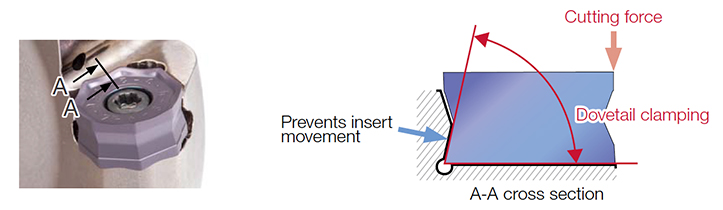

2. 燕尾槽结构实现牢固的刀片锁紧

• 特别是在高温合金材料的加工中能够提升性能。

• 延长刀具寿命。

刀片 & 材质

刀体

实际案例

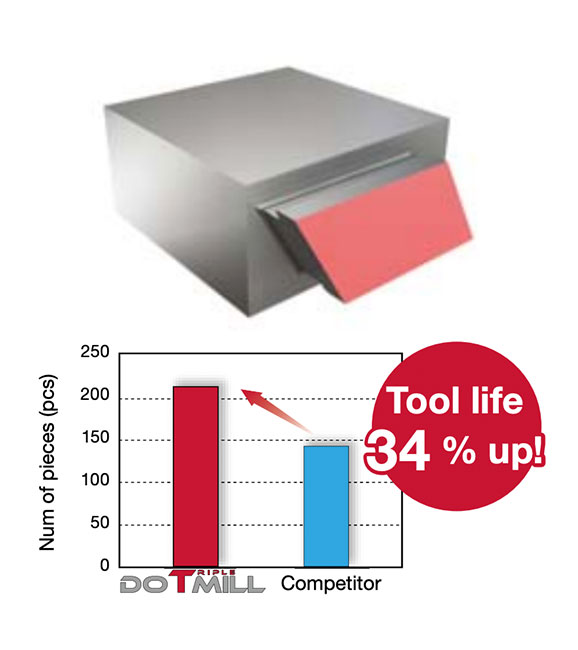

案例 #1

发电行业

| 零件: | 涡轮叶片 |

| 材料: | 10705BU (Stainless steel) |

| 刀盘: | TASN13J100B31.7R08 (ø100, z = 8) |

| 刀片: | ONGU0507ANEN-MJ |

| 材质: | AH3135 |

| 加工条件: | Vc = 79 (m/min) fz = 0.10 (mm/t) Vf = 201 (mm/min) ap = 2.0 (mm) 应用: 平面铣削(粗加工) 冷却方式: 外冷 机床: 卧式加工中心, BT50 |

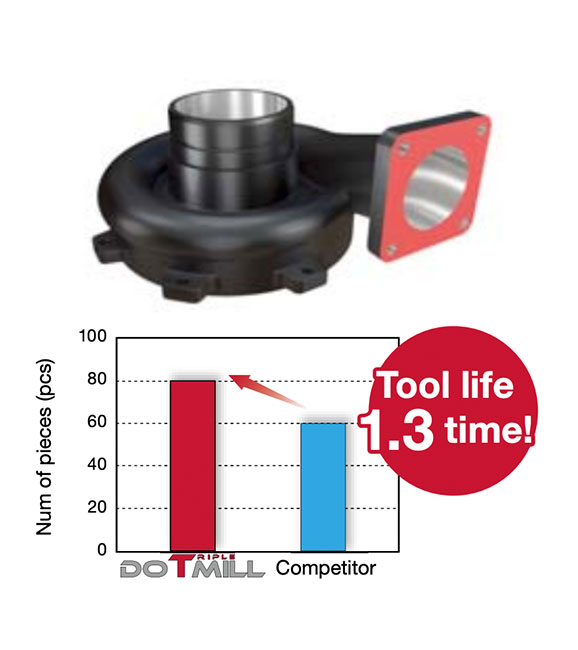

案例 #2

汽车行业

| 零件: | 涡轮壳 |

| 材料: | GX40CrNiSiNb22-10 |

| 刀盘: | TASN13M100B32.0R08 (ø100, z = 8) |

| 刀片: | SNGU1307ANEN-MJ |

| 材质: | AH3135 |

| 加工条件: | Vc = 94 (m/min) fz = 0.17 (mm/t) Vf = 408 (mm/min) ap = 3.5 (mm) ae = 80 (mm) 应用: 平面铣削 冷却方式: 外冷 机床: 立式加工中心 |

案例 #3

汽车行业

| 零件: | 涡轮壳 |

| 材料: | Hi Si FCD |

| 刀盘: | TASN13M125B40.0R10 (ø125, z = 10) |

| 刀片: | SNGU1307ANEN-MJ |

| 材质: | AH3135 |

| 加工条件: | Vc = 196 (m/min) fz = 0.08 (mm/t) Vf = 400 (mm/min) ap = 1.3 (mm) ae = 100 (mm) 应用: 平面铣削 (粗加工) 冷却方式: 外冷 机床: 立式加工中心, BT50 |

标准加工条件

SNMU / SNGU / ONMU / ONGU

| ISO | Workpiece materials | Hardness | Priority | Grades | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, etc. C15, etc. |

200 – 300HB | First choice | AH3225 | MJ | 100 – 250 | 0.1 – 0.5 | ||

| For wear resistance | T3225 | MJ | 200 – 350 | 0.1 – 0.4 | ||||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

150 – 300HB | First choice | AH3225 | MJ | 100 – 250 | 0.1 – 0.4 | ||

| For wear resistance | T3225 | MJ | 180 – 300 | 0.1 – 0.4 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | 0.1 – 0.4 | ||

| For wear resistance | T3225 | MJ | 150 – 250 | 0.1 – 0.4 | ||||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | 0.1 – 0.35 | ||

| For wear resistance | T3225 | MJ | 100 – 200 | 0.1 – 0.3 | ||||

| Cast stainless steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MH | 60 – 120 | 0.1 – 0.3 | ||

| For low cutting force | AH3135 | MJ | 60 – 120 | 0.1 – 0.3 | ||||

| Grey cast iron FC250, etc. 250, etc. |

150 – 250HB | First choice | AH8015 | MJ | 100 – 250 | 0.1 – 0.5 | ||

| For wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.4 | ||||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | AH8015 | MJ | 80 – 200 | 0.1 – 0.5 | ||

| For wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.4 | ||||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MJ | 30 – 60 | 0.1 – 0.3 | ||

| For wear resistance | AH8015 | MJ | 30 – 60 | 0.1 – 0.3 | ||||

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH8015 | MJ | 10 – 40 | 0.05 – 0.15 | ||

| For fracture resistance | AH3135 | MJ | 10 – 40 | 0.05 – 0.15 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 | MJ | 80 – 130 | 0.05 – 0.2 | |

| For fracture resistance | AH3225 | MJ | 80 – 130 | 0.05 – 0.2 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | MJ | 50 – 70 | 0.03 – 0.1 | ||

RNMU

| ISO | Workpiece materials | Hardness | Priority | Grades | Chip-breaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, etc. C15, etc. |

200 – 300HB | First choice | AH3225 | MJ | 100 – 250 | ※ap = 6 mm : 0.1 – 0.3 ※ap = 2 mm : 0.4 – 0.8 ※ap = 1 mm : 0.8 – 1.5 |

||

| For wear resistance | T3225 | MJ | 200 – 350 | |||||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

150 – 300HB | First choice | AH3225 | MJ | 100 – 250 | |||

| For wear resistance | T3225 | MJ | 180 – 300 | |||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | |||

| For wear resistance | T3225 | MJ | 150 – 250 | |||||

| Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | ※ap = 6 mm : 0.1 – 0.25 ※ap = 2 mm : 0.3 – 0.7 ※ap = 1 mm : 0.6 – 1.3 |

||

| For wear resistance | T3225 | MJ | 100 – 200 | |||||

| Stainless cast steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MJ | 60 – 120 | ※ap = 2 mm : 0.2 – 0.4 ※ap = 1 mm : 0.3 – 0.8 |

||

| For fracture resistance | AH3135 | MJ | 60 – 120 | |||||

| Grey cast iron FC250, etc. 250, etc., GG25, etc. |

150 – 250HB | First choice | AH120 | MJ | 100 – 300 | ※ap = 6 mm : 0.1 – 0.3 ※ap = 2 mm : 0.4 – 0.8 ※ap = 1 mm : 0.8 – 1.5 |

||

| T1215 | MJ | 100 – 250 | ||||||

| Ductile cast iron FCD600, etc. 600-3, etc., GGG60, etc. |

150 – 250HB | First choice | AH120 | MJ | 100 – 300 | |||

| T1215 | MJ | 80 – 200 | ||||||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MJ | 30 – 60 | ap = 1 mm : 0.15 – 0.8 | ||

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH120 | MJ | 10 – 40 | ap = 1 mm : 0.05 – 0.3 | ||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | MJ | 80 – 130 | ap = 1 mm : 0.1 – 0.25 | |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH120 | MJ | 50 – 70 | ap = 0.5 mm : 0.03 – 0.1 | ||

※ When using T3225 or T1215, decrease the feed per tooth (fz) to 80% of the abovementioned value.