拥有8个刀尖刀片的面铣刀,可实现最佳离隙角

带8个刀尖刀片的铣刀,用于高效平面铣削加工

应用 & 特点

应用

特点

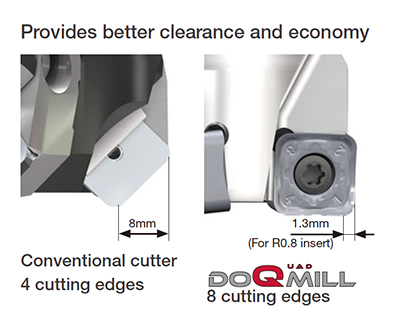

1. 拥有大离隙角和经济性的平面铣刀

• 设计用于平面铣削粗加工和精加工中避免刀具干涉。

• 修光刃刀片能够满足精密的表面精度要求。

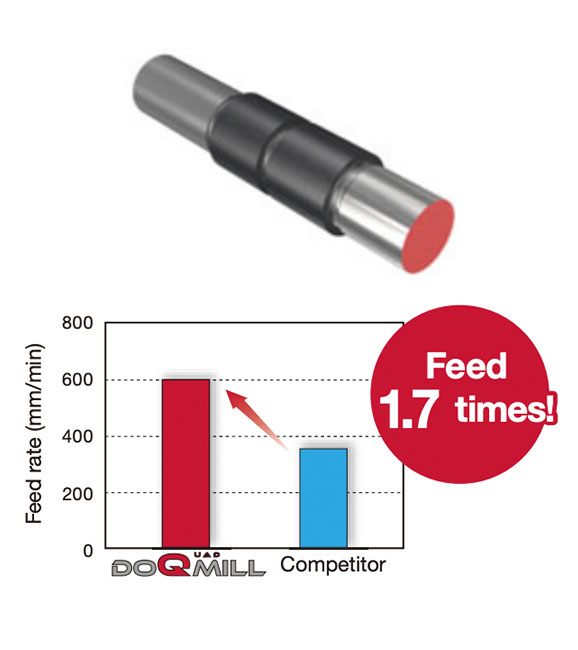

2. 优化的刀具设计降低了切削力并防止振刀

• 因为凹形设计的切削刃形状实现了稳定的切削性能。

• 高抗崩损性的坚固刀片。

刀片 & 材质

刀体

实际案例

案例 #1

汽车行业

| 零件: | 转向节 |

| 材料: | FCD450 |

| 刀盘: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| 刀片: | SNMU120620EN-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 142 (m/min) fz = 0.22 (mm/t) Vf = 800 (mm/min) ap = 2 (mm) ae = 30 (mm) 应用: 平面铣削 冷却方式: 外冷 机床: 立式加工中心 |

案例 #2

汽车行业

| 零件: | 轴 |

| 材料: | 合金钢 (35HRC) |

| 刀盘: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| 刀片: | SNMU120620EN-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 236 (m/min) fz = 0.1 (mm/t) Vf = 600 (mm/min) ap = 2 (mm) ae = 35 (mm) 应用: 平面铣削 冷却方式: 外冷 机床: 立式加工中心 |

案例 #3

汽车行业

| 零件: | 轴 |

| 材料: | 合金钢 |

| 刀盘: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| 刀片: | SNMU120620EN-MM |

| 材质: | AH3135 |

| 加工条件: | Vc = 157 (m/min) fz = 0.2 (mm/t) Vf = 800 (mm/min) ap = 2 (mm) ae = 40 (mm) 应用: 方肩铣削 冷却方式: 外冷 机床: 立式加工中心 |

标准加工条件

| ISO | Workpiece materials | Hardness | Priority | Grades | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steels S15C, etc. C15E4, etc., C15E, etc. |

– 200HB | First choice | AH3225 | MM | 100 – 250 | 0.06 – 0.3 | |

| For wear resistance | T3225 | MM | 200 – 350 | 0.06 – 0.25 | |||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 250 | 0.06 – 0.3 | |

| For wear resistance | T3225 | MM | 180 – 300 | 0.06 – 0.25 | |||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MM | 100 – 200 | 0.06 – 0.25 | |

| For wear resistance | T3225 | MM | 150 – 250 | 0.06 – 0.2 | |||

| Austenitic stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MM | 100 – 200 | 0.06 – 0.25 | |

| For wear resistance | T3225 | MM | 100 – 200 | 0.06 – 0.2 | |||

| Cast stainless steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MM | 60 – 120 | 0.06 – 0.2 | |

| For fracture resistance | AH3135 | MM | 60 – 120 | 0.06 – 0.2 | |||

| Grey cast iron FC250, etc. 250, etc., GG25, etc. |

150 – 250HB | First choice | AH8015 | MM | 100 – 350 | 0.06 – 0.3 | |

| For fracture resistance | T1215 | MM | 100 – 250 | 0.06 – 0.3 | |||

| Ductile cast iron FCD600, etc. 600-3, etc., GGG60, etc. |

150 – 250HB | First choice | AH8015 | MM | 100 – 350 | 0.06 – 0.25 | |

| For fracture resistance | T1215 | MM | 80 – 200 | 0.06 – 0.3 | |||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MM | 30 – 60 | 0.06 – 0.2 | |

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH8015 | MM | 10 – 40 | 0.04 – 0.16 | |

| Hardened steel SKD61, etc., X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | MM | 80 – 130 | 0.04 – 0.16 | |

| Hardened steel SKD11, etc., X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | MM | 50 – 70 | 0.02 – 0.08 |