拥有出色表面精度的高速面铣刀

适用于各种材料加工的高效、经济型面铣刀

应用 & 特点

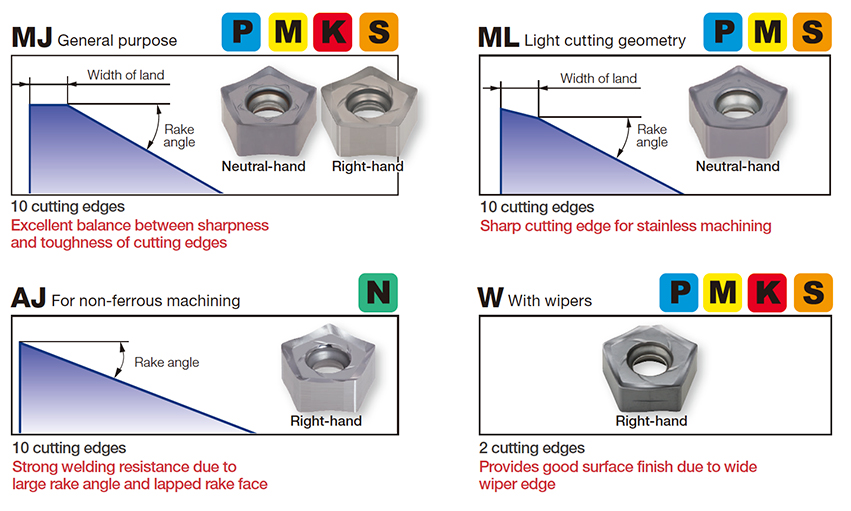

应用

特点

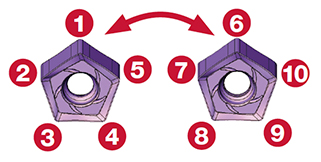

1. 经济的五边形刀片

• 10个刀尖双面刀片

2. 低切削力

3. 刀片阵容丰富可用于各种加工

刀片 & 材质

刀体

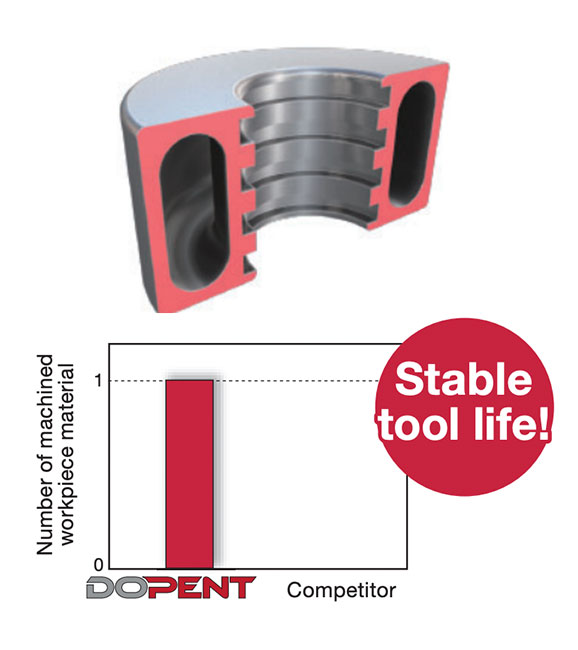

实际案例

案例 #1

通用工程

| 零件: | 泵壳 |

| 材料: | SKD11 |

| 新刀: | TEN09R125M38.1-06 (ø125 mm, z = 6) |

| 刀片: | PNCU0905GNEN-ML |

| 材质: | AH3135 |

| 加工条件: | Vc = 120 (m/min) fz = 0.25 (mm/t) Vf = 458 (mm/min) ap = 3 (mm) ae = 60 (mm) 应用: 平面铣削 冷却方式: 干式 机床: 卧式加工中心 |

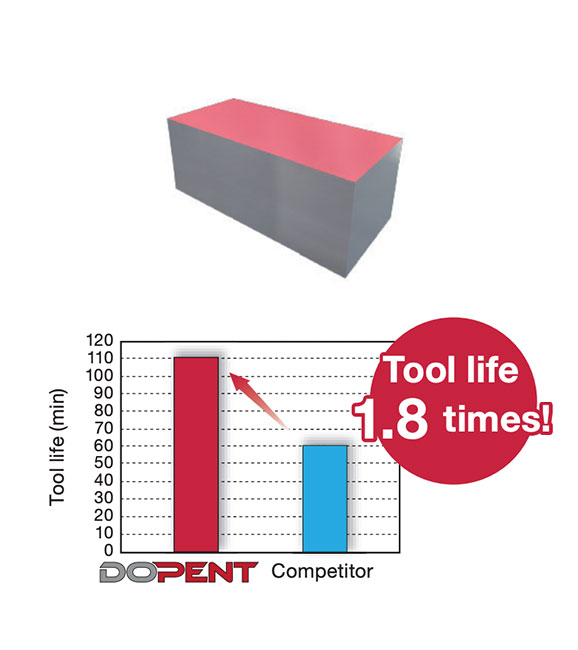

案例#2

通用工程

| 零件: | 轧制模材料 |

| 材料: | 工具钢 |

| 铣刀: | TEN09R160M50.8-12 (ø160 mm, z = 12) |

| 刀片: | PNMU0905GNEN-MJ |

| 材质: | AH3225 |

| 加工条件: | Vc = 300 (m/min) fz = 0.1 (mm/t) Vf = 716 (mm/min) ap = 0.8 (mm) ae = 50 (mm) 应用: 面铣 冷却方式: 干式 机床: 卧式加工中心 |

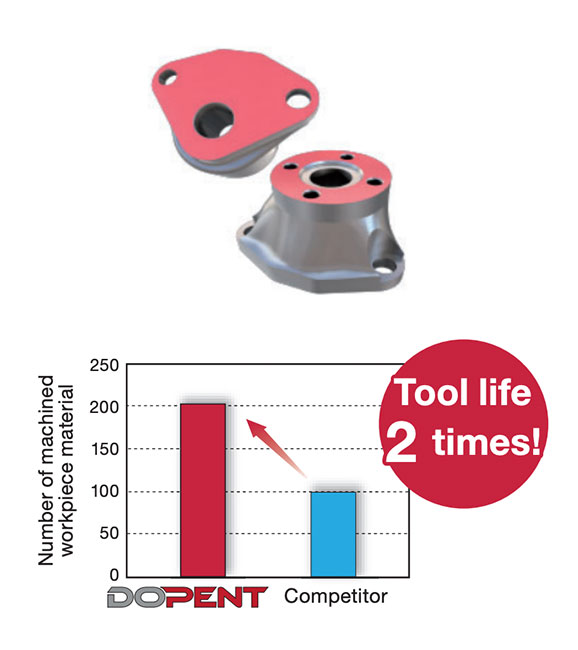

案例 #3

通用工程

| 零件: | EGR 阀门 |

| 材料: | FC250 / 250 |

| 铣刀: | TEN09R125M38.1-06 (ø125 mm, z = 6) |

| 刀片: | PNCU0905GNEN-MJ |

| 材质: | AH120 |

| 加工条件: | Vc = 390 (m/min) fz = 0.15 (mm/t) Vf = 900 (mm/min) ap = 0.9 (mm) ae = 75 (mm) 应用: 面铣 冷却方式: 外冷 机床: 立式加工中心、6kW |

| 工序: | , |

| 机床: |

标准加工条件

| ISO | Workpiece materials | Hardness | Selection criteria |

Recommended grade |

Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steels S15C, C15E4, etc. C15, etc. |

200 – 300 HB | First choice | AH3225 | MJ | 100 – 250 | 0.1 – 0.4 | |

| 200 – 300 HB | Low cutting force | AH3225 | ML | 100 – 250 | 0.1- 0.3 | ||

| 200 – 300 HB | Wear resistance | T3225 | MJ | 200 – 350 | 0.1- 0.3 | ||

| 200 – 300 HB | Surface quality | NS740 | MJ | 100 – 250 | 0.1- 0.3 | ||

| High carbon steels, alloyed steels S45C, SCM440, etc. C45, 42CrMo4, etc. |

150 – 300 HB | First choice | AH3225 | MJ | 100 – 250 | 0.1- 0.35 | |

| 150 – 300 HB | Low cutting force | AH3225 | ML | 100 – 250 | 0.1- 0.3 | ||

| 150 – 300 HB | Wear resistance | T3225 | MJ | 180 – 300 | 0.1- 0.3 | ||

| 150 – 300 HB | Surface quality | NS740 | MJ | 100 – 250 | 0.1- 0.3 | ||

| Prehardened steels NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | 0.1- 0.3 | |

| 30 – 40 HRC | Low cutting force | AH3225 | ML | 100 – 200 | 0.1- 0.25 | ||

| 30 – 40 HRC | Wear resistance | T3225 | MJ | 150 – 250 | 0.1- 0.25 | ||

| Stainless steels SUS304, etc. X5CrNi18-9, etc. |

– 200 HB | First choice | AH3135 | ML | 100 – 200 | 0.1 – 0.3 | |

| – 200 HB | Fracture resistance | AH3135 | MJ | 100 – 200 | 0.1 – 0.35 | ||

| – 200 HB | Wear resistance | T3225 | MJ | 100 – 250 | 0.1 – 0.3 | ||

| Grey cast irons FCD400, etc. 250, etc. |

150 – 250 HB | First choice | AH8015 | MJ | 100 – 250 | 0.1 – 0.4 | |

| 150 – 250 HB | Wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.35 | ||

| Ductile cast irons FCD400, etc. 400-15S, etc. |

150 – 250 HB | First choice | AH8015 | MJ | 80 – 200 | 0.1 – 0.4 | |

| 150 – 250 HB | Wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.35 | ||

| Aluminium alloys Si < 13% |

– | First choice | DS2005, KS05F | AJ | 500 – 1500 | 0.1 – 0.5 | |

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005, KS05F | AJ | 150 – 500 | 0.1 – 0.5 | |

| Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH3135 | ML | 30 – 60 | 0.1 – 0.3 | |

| – 40 HRC | Fracture resistance | AH3135 | MJ | 30 – 60 | 0.1 – 0.3 | ||

| – 40 HRC | Wear resistance | AH8015 | ML | 30 – 60 | 0.1 – 0.3 | ||

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | First choice | AH8015 | MJ | 10 – 40 | 0.04 – 0.1 | |

| Hardened materials SKD61, X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | MJ | 80 – 150 | 0.05 – 0.15 | |

| 40 – 50 HRC | Fracture resistance | AH3225 | MJ | 80 – 150 | 0.05 – 0.15 |

- 使用压缩空气清除多余的切屑防止塞屑。

- 使用水基冷却液避免刃口积屑瘤的产生,防止刀尖熔敷。 (如铝合金加工).

- 对于切深不均匀的加工(如铸造表面)和工件材料断续表面的加工,进给(fz)的设置应该低于上表所示的推荐值。

- 加工条件可能受限于机床功率,工件刚性和主轴输出。当切宽、切深或悬伸长度较大时,Vc和fz的设置应该低于推荐值并确认机床的功率和振动情况。