钢和铸铁加工用面铣刀

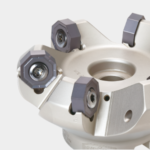

一款刀体可分别选择安装4种刀片拓宽了其应用范围

应用 & 特点

应用

特点

1. 可选择安装单面或双面刀片

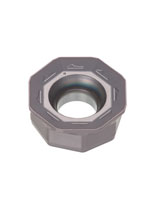

- ONMU / ONHU: 双面, 八边形刀片 (经济性好)

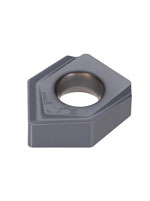

- SNMU / SNHU: 双面, 四边形刀片 (大切深)

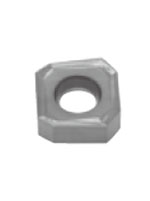

- OWMT: 单面, 八边形刀片(低切削负载,大进给速度)

2. 丰富的刀体阵容

• 包括直径 >ø315 mm 的刀盘或超密齿距设计用于铸铁高效铣削加工。

通用目的

位于大容屑槽上优化的冷却液出口位置有助于实现顺畅的排屑。大尺寸锁紧螺钉提高了刀片的安全性。

刀盘直径: ø80 mm – ø315 mm

实现高效的铸铁铣削

提供了相对于螺钉锁紧式刀盘两倍的刀片,且刀片转位方便。

刀盘直径: ø80 mm – ø160 mm

刀片 & 材质

刀片

主要材质

刀体

实际案例

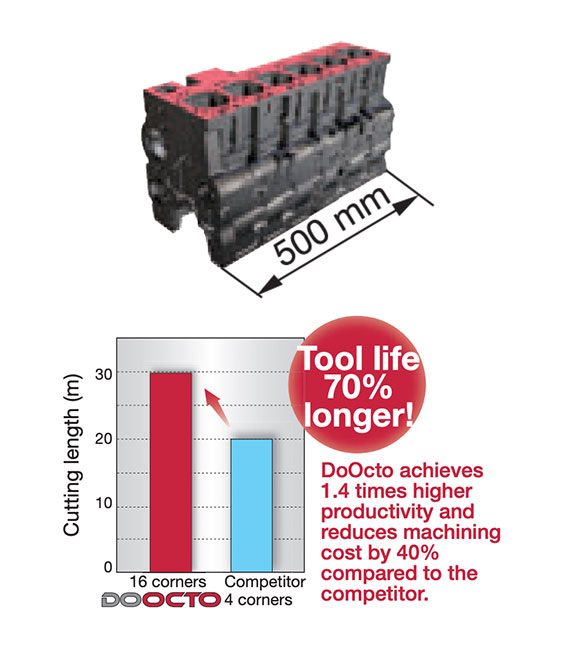

案例 #1

汽车行业

| 零件: | 缸体 |

| 材料: | FC250 |

| 刀盘: | TAN07R160M50.8-15 (ø160 mm, z = 15) |

| 刀片: | ONHU0705ANTN-ML |

| 材质: | AH120 |

| 加工条件: | Vc = 180 (m/min) fz = 0.18 → 0.2 (mm/t) Vf = 780 → 1080 (mm/min) ap = 3 (mm) ae = 100 (mm) 应用: 平面铣削 冷却方式: 干切 机床: 立式加工中心, BT50 |

案例 #2

汽车行业

| 零件: | 曲轴 |

| 材料: | SCM435 / 34CrMo4 |

| 刀盘: | TAN07R100M31.7-07 (ø100 mm, z = 7) |

| 刀片: | ONMU0705ANPN-ML |

| 材质: | AH3135 |

| 加工条件: | Vc = 80 (m/min) fz = 0.18 (mm/t) Vf = 320 (mm/min) ap = 3 (mm) ae = 75 (mm) 应用: 平面铣削 冷却方式: 冷却液 机床: 专机 |

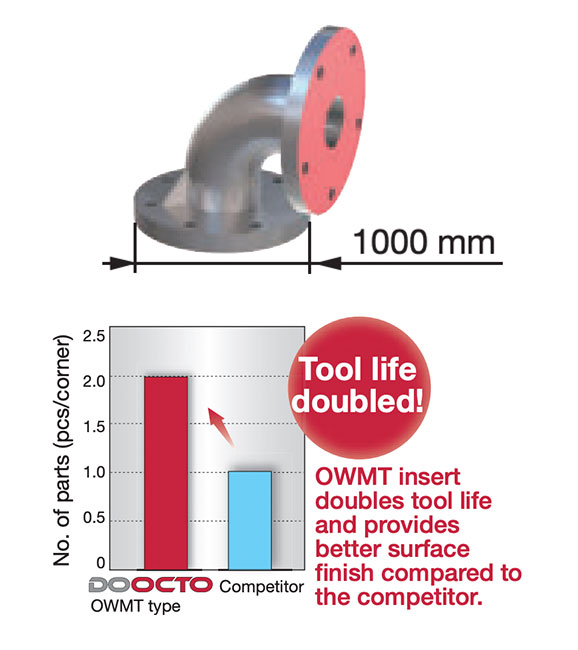

案例 #3

通用工程

| 零件: | 弯头 |

| 材料: | SCS10 / 25Cr5NiMoN |

| 刀盘: | TAN07R200M47.6-12 (ø200 mm, z = 12) |

| 刀片: | OWMT0807AAER-ML |

| 材质: | AH3135 |

| 加工条件: | Vc = 70 (m/min) fz = 0.2 (mm/t) Vf = 267 (mm/min) ap = 1 (mm) ae = 180 (mm) 应用: 平面铣削 冷却方式: 冷却液 机床: 卧式加工中心, BT50 |

标准加工条件

Negative type

| ISO | Workpiece material | Hardness | Priority | Recommendation | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|

| Grade | Chipbreaker | ||||||

| Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200HB | First choice | AH3225 | MJ | 100 – 250 | 0.2 – 0.5 | |

| – 200HB | Fracture resistance | AH3135 | MJ | 100 – 250 | 0.2 – 0.5 | ||

| – 200HB | Wear resistance | T3225 | MJ | 200 – 350 | 0.2 – 0.4 | ||

| – 200HB | Low cutting force | AH3225 | ML | 100 – 250 | 0.2 – 0.4 | ||

| High carbon steel S45C, S55C, etc. C45, C55, etc. |

200 – 300 HB | First choice | AH3225 | MJ | 100 – 230 | 0.2 – 0.4 | |

| 200 – 300 HB | Fracture resistance | AH3135 | MJ | 100 – 230 | 0.2 – 0.4 | ||

| 200 – 300 HB | Wear resistance | T3225 | MJ | 180 – 300 | 0.2 – 0.4 | ||

| 200 – 300 HB | Low cutting force | AH3225 | ML | 100 – 230 | 0.2 – 0.4 | ||

| Alloy steel SCM440, SCr415, etc. 42CrMo4, 17Cr3, etc. |

150 – 330 HB | First choice | AH3225 | MJ | 100 – 200 | 0.2 – 0.4 | |

| 150 – 330 HB | Fracture resistance | AH3135 | MJ | 100 – 200 | 0.2 – 0.4 | ||

| 150 – 330 HB | Wear resistance | T3225 | MJ | 150 – 250 | 0.2 – 0.4 | ||

| 150 – 330 HB | Low cutting force | AH3225 | ML | 100 – 200 | 0.2 – 0.4 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | 0.1 – 0.3 | |

| – 200HB | Wear resistance | T3225 | MJ | 100 – 250 | 0.1 – 0.3 | ||

| Grey cast iron FC350, FC450 etc. GG35, GG45, etc. |

150 – 250HB | First choice | AH8015 | MJ | 100 – 250 | 0.1 – 0.5 | |

| 150 – 250HB | Wear resistance | T1215 | MJ | 150 – 300 | 0.1 – 0.5 | ||

| 150 – 250HB | Low cutting force | AH8015 | ML | 100 – 250 | 0.1 – 0.5 | ||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 300HB | First choice | AH8015 | MJ | 80 – 200 | 0.1 – 0.5 | |

| 150 – 300HB | Wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.5 | ||

| 150 – 300HB | Low cutting force | AH8015 | ML | 80 – 200 | 0.1 – 0.5 | ||

| Titanium alloy Ti-6Al-4V, etc. |

– HRC 40 | First choice | AH3135 | ML | 30 – 60 | 0.1 – 0.3 | |

| Heat resistant alloy Inconel718, etc. |

– HRC 40 | First choice | AH8015 | ML | 10 – 40 | 0.05 – 0.15 | |

| Hardened steel | 40 – 50HRC | First choice | AH8015 | MJ | 80 – 130 | 0.1 – 0.2 | |

| 40 – 50HRC | Fracture resistance | AH3225 | MJ | 80 – 130 | 0.1 – 0.2 | ||

| 50 – 60HRC | First choice | AH8015 | MJ | 50 – 70 | 0.05 – 0.1 | ||

Positive type

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) | |

|---|---|---|---|---|---|---|---|

| ML | HJ* | ||||||

| Low carbon steel S15C, SS400, etc. C15E, etc. |

– 200HB | First choice | AH3135 | 100 – 300 | 0.1 – 0.4 | 0.5 – 1.5 | |

| High carbon steel S45C, S55C, etc. C45, C55, etc. |

200 – 300 HB | First choice | AH3135 | 100 – 230 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Alloy steel SCM440, SCr415, etc. 42CrMo4, 17Cr3, etc. |

150 – 330 HB | First choice | AH3135 | 100 – 200 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | AH3135 | 100 – 150 | 0.1 – 0.3 | 0.3 – 0.7 | |

| – 200HB | Fracture resistance | AH130 | 100 – 150 | 0.1 – 0.3 | – | ||

| Grey cast iron FC350, FC450 etc. GG35, GG45, etc. |

150 – 250HB | First choice | AH3135 | 100 – 250 | 0.1 – 0.4 | 0.5 – 1.5 | |

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | AH3135 | 80 – 200 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Titanium alloy Ti-6Al-4V, etc. |

– HRC 40 | First choice | AH3135 | 30 – 60 | 0.1 – 0.3 | 0.3 – 0.7 | |

| – HRC 40 | Fracture resistance | AH130 | 30 – 60 | 0.1 – 0.3 | – | ||

| Heat resistant alloy Inconel718, etc. |

– HRC 40 | First choice | AH3135 | 10 – 40 | 0.05 – 0.15 | 0.1 – 0.3 | |

| – HRC 40 | Fracture resistance | AH130 | 10 – 40 | 0.05 – 0.15 | – | ||

| Hardened steel | 40 – 50HRC | First choice | AH3135 | 80 – 130 | – | 0.1 – 0.3 | |

| 50 – 60HRC | First choice | AH3135 | 50 – 70 | – | 0.03 – 0.07 | ||