日本磐城 – 2026 年 1 月 – Tungaloy Corporation(社長:木下 聡、總公司:福島縣磐城市)宣布將其 PVD 等級 AH8015 應用擴展至四個銑削刀具系列—DoForceTri、MillQuadFeed、TungTriShred 和 DoQuadMill—從而增強各種銑削操作的耐磨性和刀具壽命。

挑戰與趨勢

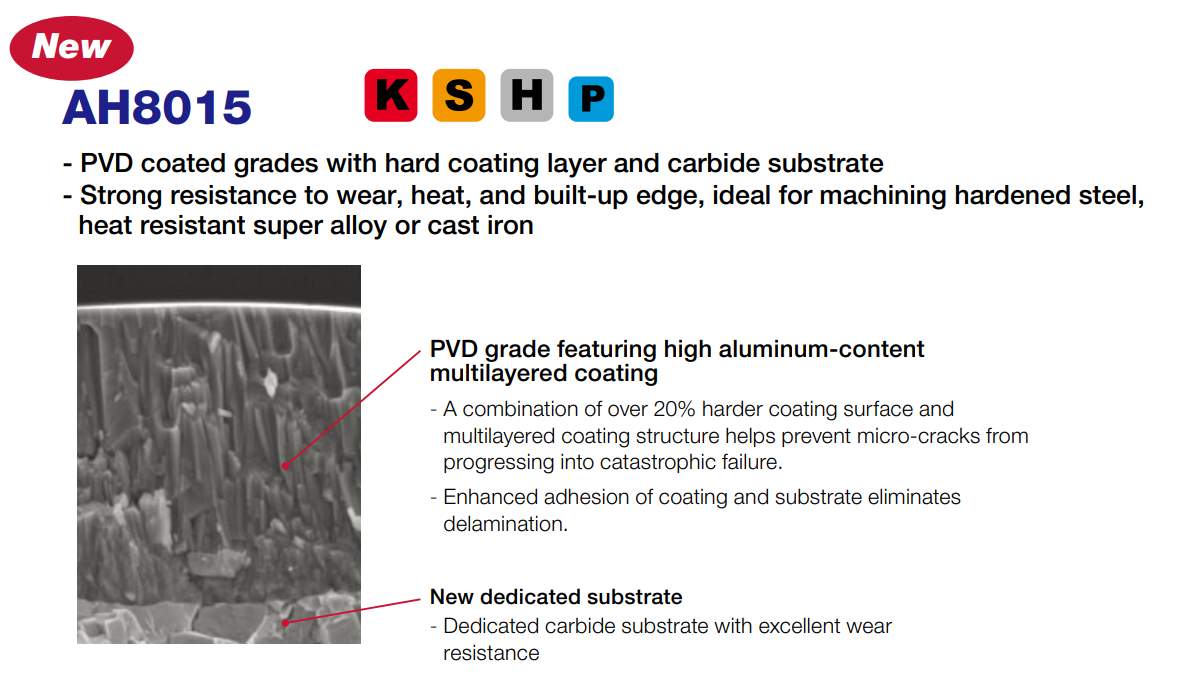

在汽車、工程機械、航空航天和模具製造等廣泛的行業中,對提高生產效率和降低成本的需求比以往任何時候都更加強烈。 特別是,在鑄鐵、耐熱合金和淬硬鋼等難切削材料時,由於磨損而頻繁更換刀具成為提高生產率的主要障礙。

在這些市場條件下,對能夠提供更長刀具壽命和穩定性能的高耐磨刀具的需求正在迅速增長。 為了應對這一挑戰,Tungaloy 已將 PVD 等級 AH8015 擴展到四個銑削刀具系列,從而在難切削材料中提供高可靠性和成本效益。

產品概述

DoForce-Tri

Application: Cutter for shoulder milling and face milling.

Features:

- Uses double-sided inserts with six cutting corners to reduce cost and improve productivity.

- Capable of a wide range of machining such as shoulder milling and slotting.

- Curved cutting edge design reduces cutting resistance while maintaining good chip evacuation.

👉 A tool suitable for applications where improving the efficiency and economy of shoulder milling is desired.

TungTriShred

Application: High-productivity roughing cutter for shoulder milling and slotting.

Features:

- Serrated cutting edges split chips to suppress chatter.

- Two types of inserts can be used on the same cutter body.

- Delivers stable high-efficiency rough machining even with long overhangs.

👉 Ideal for situations where you want to suppress chatter and increase rough machining efficiency.

DoQuadMill

Application: Face milling cutter for general face milling, including near walls and corners.

Features:

- Uses 8-corner inserts with a focus on economy and accessibility.

- Supports rough to finish face milling while avoiding interference.

- Low resistance and low cutting forces make it strong even with unstable workpieces.

👉 A tool suitable for face milling and corner cutting where accessibility is required.

MillQuadFeed

Application: Milling cutter for high-feed machining.

Features:

- Two types of inserts with different entry angles can be mounted on the same body.

- High rigidity and low resistance design enables high-efficiency machining and long tool life.

- Supports a wide range of applications including shoulder milling and plunging.

👉 A versatile cutter that enables high-feed machining tailored to different applications by changing the entry angle.