日本磐城 – 2025 年 10 月 – Tungaloy Corporation(社長:木下 智,總公司:福島縣磐城市)宣布擴展其 T9200 系列,現在採用 RCMX3209M0 刀片,以增強鐵路車輪和重型切削應用中的性能。

Challenges and Trends

在鐵路車輪加工和一般重型切削等機械加工應用中,高切削性能和穩定性至關重要。 然而,適用於這些嚴苛操作的 RCMX3209M0 形刀片尚未包含在我們 T9200 系列的標準產品陣容中。 因此,在嚴苛的切削條件下,經常發生刀片崩刃性或斷裂,在某些情況下,甚至導致刀柄損壞,從而在生產力和成本方面帶來挑戰。 為了回應這些使用者的疑慮,強烈要求擴大刀片形狀的範圍,以更好地滿足這些「挑戰和市場條件」。

Product Overview

T9200 系列是專為鋼件車削應用設計的下一代 CVD 塗層等級。 它結合了出色的耐磨性和高韌性,確保了穩定且長的刀具壽命。 它能夠承受高速切削,是在批量生產環境中實現高效加工的理想解決方案。

Benefits and Features

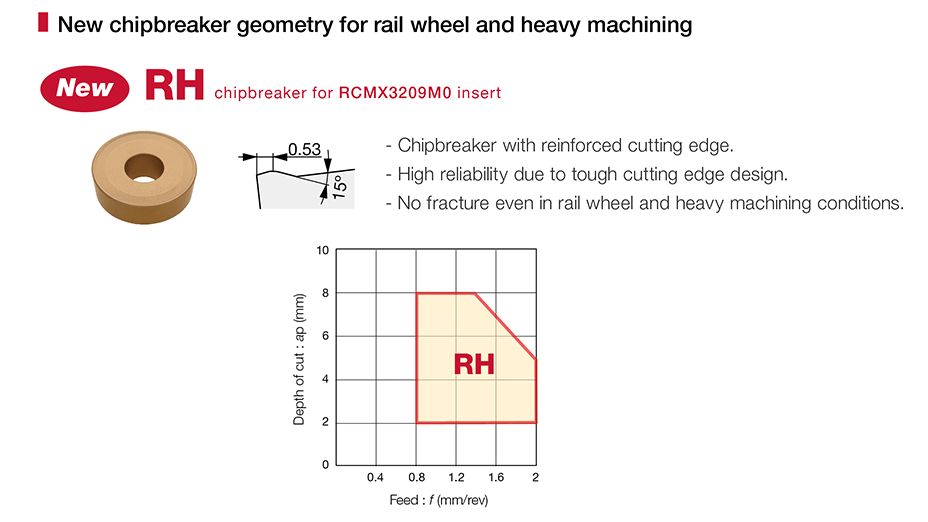

Feature 1: High Machining Stability with Reinforced Cutting Edge Breaker

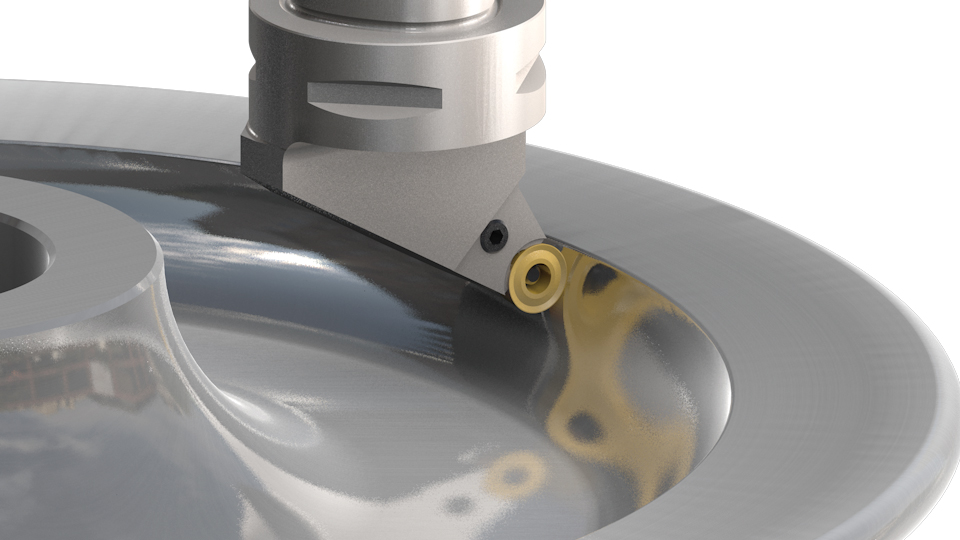

– The RCMX3209M0-RH features the newly developed RH breaker with a robust cutting edge design.

– The reinforced edge prevents chipping and breakage even under high-load conditions such as heavy-duty cutting and railway wheel machining.

– Minimizes machining troubles and ensures reliable continuous operation.

Feature 2: Balanced Wear and Fracture Resistance with T9205 Grade

– T9205 employs a high-hardness substrate and a heat-resistant coating for superior durability.

– In combination with the RH breaker, it delivers long tool life and stable cutting performance.

– Reduces tool change frequency, contributing to cost savings and improved productivity.

Success Stories

IMPROVED TOOL LIFE

New RH chipbreaker with T9205 improved tool life by 1.1 times with well-balanced wear and fracture resistance.

| Industry | Heavy |

| Component | Rail wheel |

| Material ISO code | |

| Work material | Rail wheel steel |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | External & Face turning |

| Product name | T9205 |

| TSR No. | 5407T |