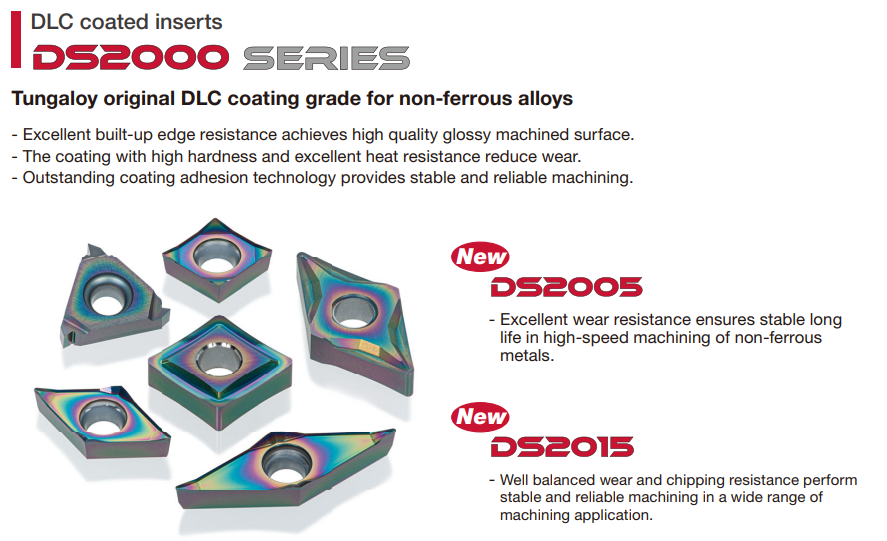

日本磐城 – 2026 年 1 月 – Tungaloy Corporation(社長:木下 聰、總公司:福島縣磐城市)宣布擴展其 DLC 塗層 DS2000 Series,該系列針對鋁和non-ferrous metals加工進行了優化,可在車削和銑削操作中提供卓越的表面光潔度、延長的刀具壽命和更高的生產力。

挑戰與趨勢

近年來,包括汽車、航空航天、半導體、機器人和房屋材料在內的眾多行業,都加速了輕量化設計和更高效率的趨勢。 其中,以輕量且高強度特性著稱的鋁合金和non-ferrous metals的採用正在迅速擴大。 因此,對這些材料進行高精度和高效加工的需求正在增加。

然而,鋁在切削過程中容易出現積屑瘤形成和毛刺產生等問題,因此難以維持穩定的刀具壽命和一致的表面光潔度品質。 在市場上,非常需要能夠克服這些挑戰,同時實現生產力和品質的加工解決方案。

產品概述

ISO-insert

Application:

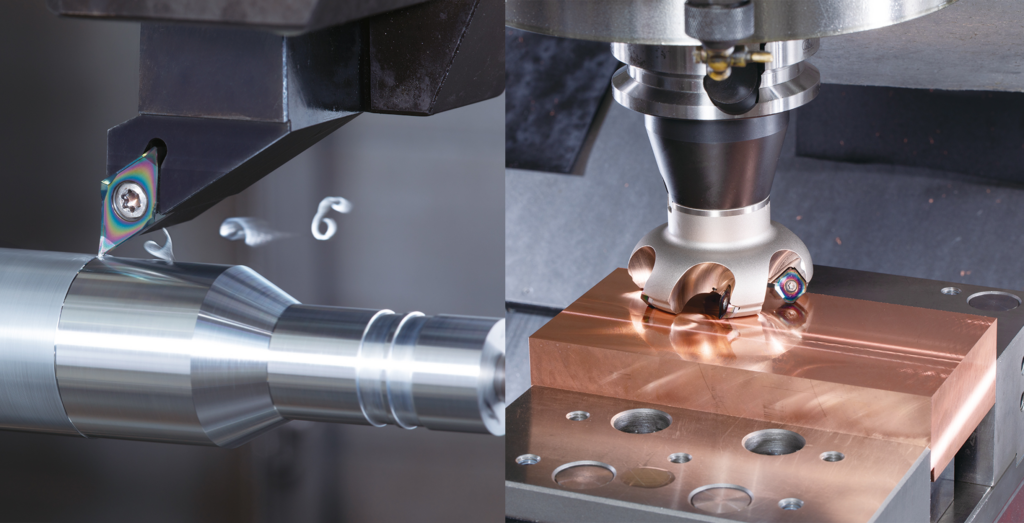

DLC-coated grade for non-ferrous metal ISO turning (e.g., external turning).

Features:

- Excellent built-up edge (BUE) / adhesion resistance, delivering a bright, high-quality surface finish.

- High hardness and heat resistance help suppress wear progression for stable, long tool life.

- Strong coating adhesion supports reliable and stable machining.

- Non-ferrous chipbreaker lineup: AL (positive) / 28 (negative) for improved chip control and reduced chip entanglement.

👉 Best suited when you want stable surface finish and longer tool life in non-ferrous turning, especially where adhesion/BUE is a concern.

TungThread

Application:

DLC-coated grade for non-ferrous threading (external/internal), partial-profile type.

Features:

- Enables high thread surface quality while significantly reducing adhesion/BUE on rake and flank faces, helping slow wear.

- Ground, high-precision inserts for consistent thread quality.

- 60° / 55° partial-profile supports both external and internal threads; applicable to ISO metric (M), UN, W, and G threads.

👉 Best suited when you want stable thread quality in non-ferrous materials, minimizing adhesion, surface issues, and rapid wear

TungForce-Rec

Application:

90° square shoulder milling cutter for stable, high-efficiency milling.

Features:

- Unique V-bottom insert and clamping mechanism for stable machining.

- High-rigidity body design and secure insert clamping help prevent insert movement.

- Designed to deliver stable performance even in small-diameter applications.

👉 Best when you want reliable, high-productivity square shoulder milling with strong process stability.

Tung-Tri

Application:

Square shoulder milling cutter focused on economy and chatter stability.

Features:

- Economical 3 cutting-edge insert with large rake angle reduces cutting force and improves chip formation.

- Optimized insert flank face and differential pitch on the cutter help suppress chatter.

- Large rake/inclination angles support smooth cutting while maintaining edge strength.

👉 Best when you want cost-efficient, stable shoulder milling with good cutting action.

TungAluMill

Application:

High-speed shoulder milling for aluminum and non-ferrous materials.

Features:

- Secure, stable insert clamping design with a unique V-shaped bottom for high-speed machining.

- Cutting edge geometry optimized for aluminum machining.

- Applicable to a wide range of operations (e.g., pocketing/slotting and helical ramping).

👉 Best when you want stable high-speed Al/non-ferrous milling with broad application coverage.

DoMultiRec

Application:

Multifunctional milling cutter with center-cutting capability (incl. drilling).

Features:

- Center cutting capability enables multiple operations with a single tool, including drilling.

- Insert integrates a center and peripheral cutting edge on one side.

- Double-sided insert allows up to four indexings (front/back; center/periphery positions).

👉 Best when you want to reduce tool changes and maximize versatility with one cutter.

TFE / EFE (TungMill / TFE12, EFE12)

Application:

High-precision face milling focused on surface finish and accuracy.

Features:

- Lightweight facemill body design for high-precision machining.

- Adjustable pockets for extra precision on surface finish.

- Insert pitch (density) variations to select the best balance of economy and productivity.

👉 Best for precision face milling where controlled surface finish is critical.

DoPent

Application:

High-speed face milling with superior surface finish (all materials).

Features:

- Economical double-sided pentagonal insert with 10 cutting edges.

- Low cutting force concept supports stable machining.

- Especially suitable for thin or low-rigidity workpieces thanks to reduced cutting/radial forces.

👉 Best when you want low cost per edge + stable, high-speed face milling with good finish.

TungMill

Application:

Milling solution for steel and cast iron (face/shoulder/chamfering).

Features:

- Simulation-based design provides a lightweight cutter with low cutting load while maintaining rigidity.

- TPW/EPW type features a 4-corner insert design balancing sharpness and edge strength.

- 45° and 90° cutting edge angle supports square shoulder milling and face milling around obstacles/fixtures.

👉 Best for steel/cast-iron milling where you want accuracy, efficiency, and stable cutting behavior.

優點和特點

特點 1:透過出色的抗黏著性能實現高品質的加工表面

- 新開發的 DLC 塗層可顯著抑制與鋁和non-ferrous metals的黏著

- 防止積屑瘤形成,從而提供光亮且高度精確的表面光潔度

- 穩定的表面品質減少了對二次精加工操作的需求

特點 2:透過高硬度和耐熱性延長刀具壽命

- DLC 薄膜的高硬度最大限度地減少了刀刃磨損

- 即使在高速和高效加工中,出色的耐熱性也能確保穩定的效能

- 減少了刀具更換頻率,並有助於降低總體成本

特點 3:適用於廣泛加工應用的穩定效能

- 強大的塗層附著力可在各種操作(如車削、螺紋加工和銑削)中提供穩定的切削效能

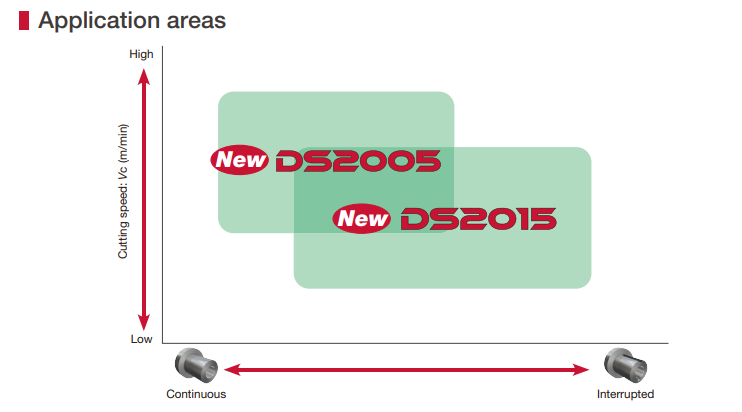

- DS2005 等級增強了耐磨性,適用於高速加工,從而延長了刀具壽命

- DS2015 等級在耐磨性和抗崩刃性之間提供了出色的平衡,從而在廣泛的條件下實現穩定的加工