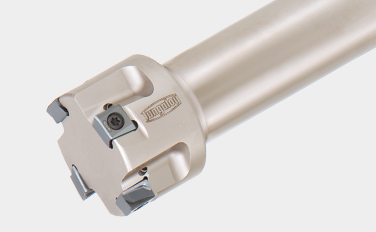

Shoulder milling cutter for roughing on medium- to large-sized machines

Tangential insert with high stability guarantees exceptional reliability in rough shouldering and finishing

Applications & Features

Applications

Features

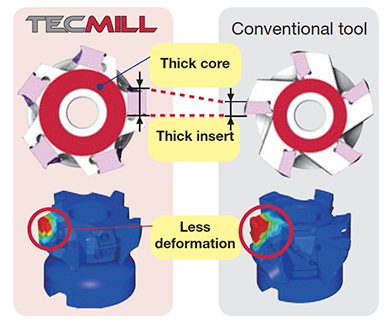

1. Reliable operation

– Highly rigid cutter with thicker core.

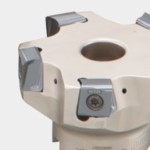

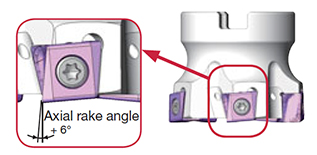

2. 4-cornered insert

– Large rake and inclination angles reduce cutting forces.

Inserts & Grades

Inserts

LMMU11/16-MJ

- Maximum depth of cut

– LNMU11-MJ: 9.7 mm

– LNMU16-MJ: 15.1 mm - 4 corners insert

- Low cutting forces and provide stable, smooth cutting

Main Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH725

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH120

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

-

Good balance between wear and fracture resistance

-

First choice for machining heat-resistant alloy under general cutting conditions

Cutter bodies

Practical examples

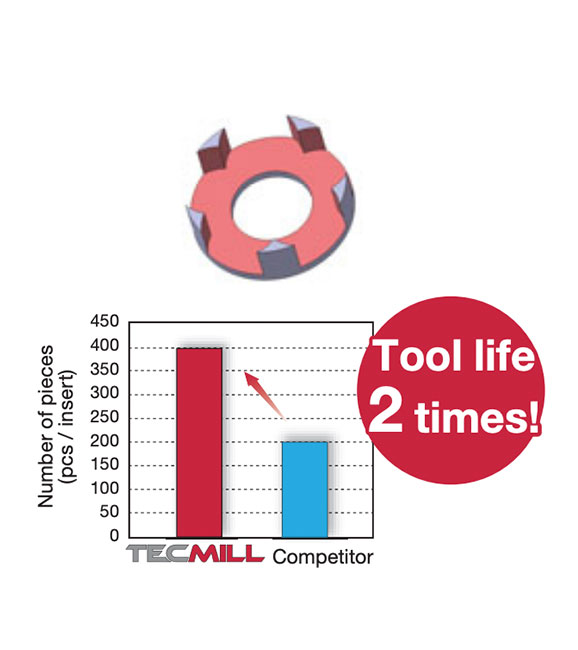

Example #1

Automotive Industry

| Part: | Planetary carrier |

| Material: | S35C |

| Cutter: | Special (ø78 mm, z = 2) |

| Insert: | LMMU160932PNER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 250 (m/min) fz = 0.1 (mm/t) Vf = 200 (mm/min) ap = 40 (mm) ae = 30 (mm) Application: Plunging Coolant: Dry Machine: Vertical M/C, BT50 |

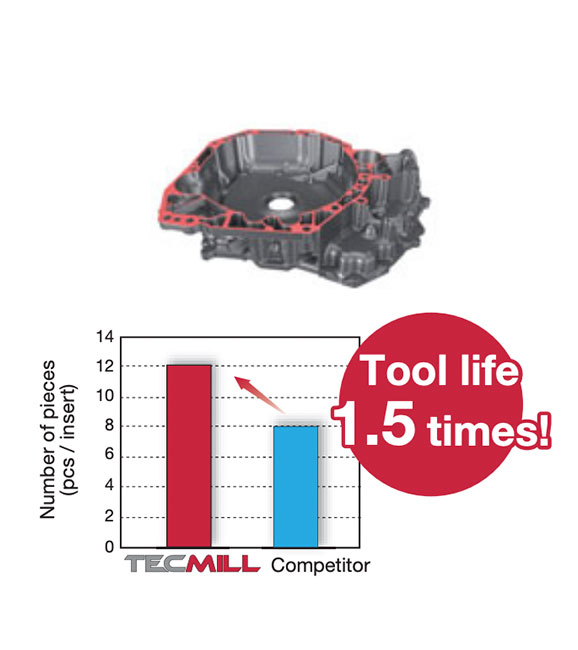

Example #2

Automotive Industry

| Part: | Gear case housing |

| Material: | FCD450 / GGG45 / 450-10S |

| Cutter: | TPM11R200U0075A05 (ø50.8 mm, z = 5) |

| Insert: | LMMU110708PNER-MJ |

| Grade: | T1215 |

| Cutting conditions: | Vc = 175 (m/min) fz = 0.15 (mm/t) Vf = 840 (mm/min) ap = 4 (mm) ae = 20 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical M/C, BT50 |

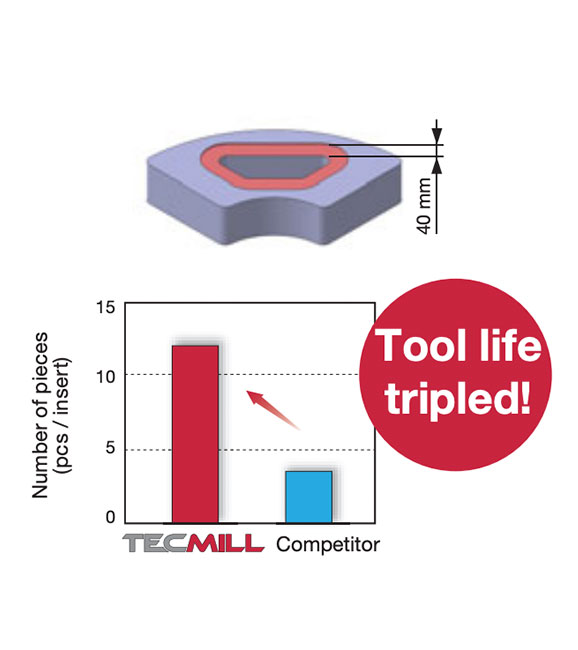

Example #3

General Engineering

| Part: | Case |

| Material: | Stainless steel |

| Cutter: | TPM16R100M31.7-06 (ø100, z = 6) |

| Insert: | LMMU160908PNER-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 100 (m/min) fz = 0.3 (mm/t) Vf = – (mm/min) ap = 10 (mm) ae = 40 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical M/C, BT50 |

Standard cutting conditions

Bore, shank type

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.05 – 0.3 | |

| – 200 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 200 HB | Fracture resistance | AH3135 | 100 – 250 | 0.05 – 0.3 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55,42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.05 – 0.25 | ||

| – 300 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 300 HB | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

| Prehardend steel NAK80, etc. PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.05 – 0.25 | ||

| 30 – 40 HRC | Wear resistance | T3225 | 120 – 350 | 0.05 – 0.2 | |||

| 30 – 40 HRC | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

|

Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | 90 – 180 | 0.05 – 0.25 | |

|

Grey cast iron FC250, etc. 250, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 300 | 0.05 – 0.3 | |

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.2 | |||

| Ductile cast iron FCD400, FCD600, etc. 600-3, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 200 | 0.05 – 0.3 | ||

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.2 | |||

|

Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH3135 | 30 – 60 | 0.05 – 0.2 | |

| Superalloys Inconel718, etc. |

– | First choice | AH8015 | 20 – 50 | 0.05 – 0.1 | ||

|

Hardened steel | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | 45 – 70 | 0.05 – 0.15 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH8015 | 40 – 65 | 0.05 – 0.1 | ||

Roughing type

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.05 – 0.25 | |

| – 200 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 200 HB | Fracture resistance | AH3135 | 100 – 250 | 0.05 – 0.25 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55,42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.05 – 0.2 | ||

| – 300 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 300 HB | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

| Prehardend steel NAK80, etc. PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.05 – 0.2 | ||

| 30 – 40 HRC | Wear resistance | T3225 | 120 – 350 | 0.05 – 0.2 | |||

| 30 – 40 HRC | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

|

Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | 90 – 180 | 0.05 – 0.25 | |

|

Grey cast iron FC250, etc. 250, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 300 | 0.05 – 0.25 | |

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.25 | |||

| Ductile cast iron FCD400, FCD600, etc. 600-3, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 200 | 0.05 – 0.25 | ||

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.25 | |||

|

Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH3135 | 30 – 60 | 0.05 – 0.15 | |

| Superalloys Inconel718, etc. |

– | First choice | AH8015 | 20 – 50 | 0.05 – 0.1 | ||

|

Hardened steel | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | 30 – 60 | 0.05 – 0.15 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH8015 | 25 – 55 | 0.05 – 0.1 | ||

For more information about this product, visit our online e-catalog or download the product report: