Highly productive and cost-effective shoulder milling cutter

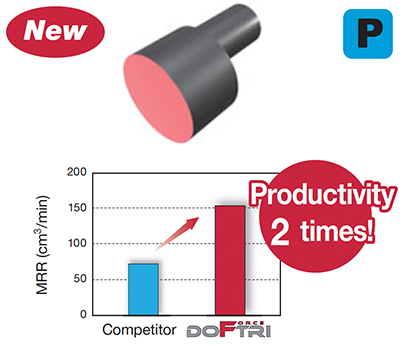

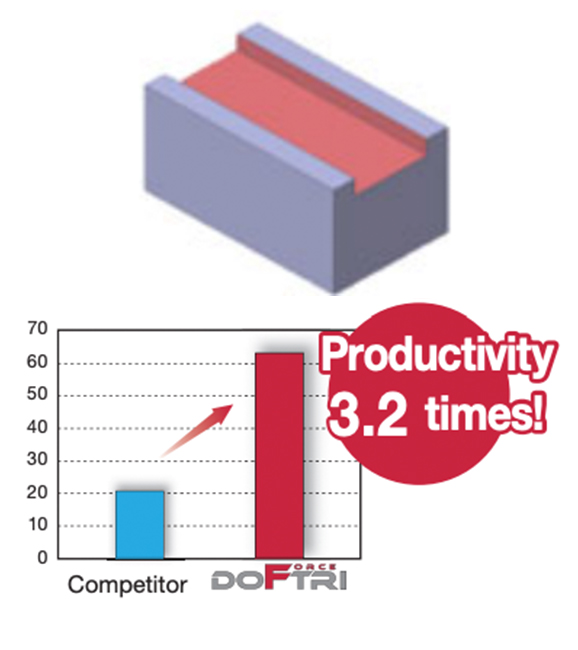

Economical shoulder mill with an innovative 6-edged geometry for maximum performance in various applications

Applications & Features

Applications

Features

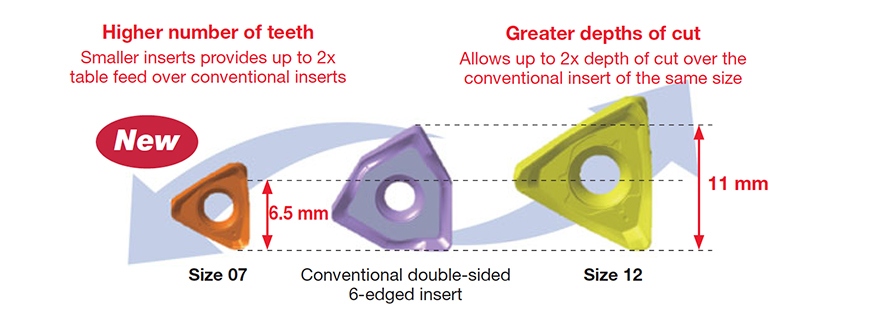

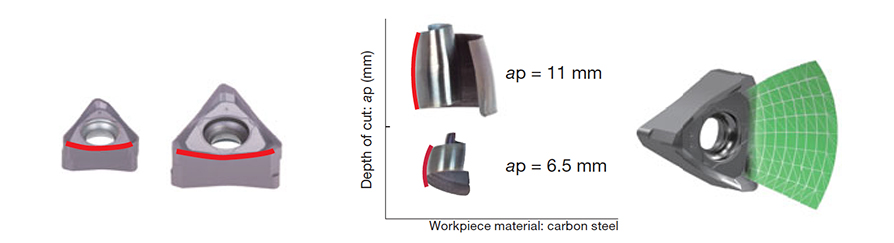

1. Innovative insert design for improved productivity

Inserts are available in 2 sizes for maximum density and cutting depths over conventional double-sided 6-edged inserts.

2. High machining flexibility

The cutting edge is configured with a large curve with an optimal inclination.

Inserts & Grades

Inserts

Main Grades

AH3135

![]()

![]()

P30 – P40 / M30 – M40

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH120

![]()

![]()

![]()

![]()

P15 – P25 / M15 – M25 / K15 – K30 / S10 – S25

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

Cutter bodies

Practical examples

Example #1

Automotive Industry

| Part: | Crankshaft |

| Material: | S55C / C55 |

| Cutter: | TPTN12M160B40.0R10N (ø160, z = 10) |

| Insert: | TNMU120708PER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 135 (m/min) fz = 0.157 (mm/t) Vf = 420 (mm/min) ap = 3 (mm) ae = 125 (mm) Application: Shoulder milling Coolant: Air blow Machine: Horizontal boring M/C, BT50 |

Example #2

General Engineering

| Part: | Machine part |

| Material: | SUS304 / X5CrNi18-9 |

| Cutter: | EPTN07M025C25.0R04 (ø25, z = 4) |

| Insert: | TNMU070308PER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 196 m/min fz = 0.13 mm/t Vf = 1298 mm/min ap = 2 mm ae = 25 mm Application: Grooving Coolant: Air Machine: Horizontal M/C, BT40 |

Example #3

Automotive Industry

| Part: | Bearing housing |

| Material: | FC250 / GG25 / 250 |

| Cutter: | EPTN07M032C32.0R05 (ø32, z = 5) |

| Insert: | TNMU070308PER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 320 m/min fz = 0.06 mm/t Vf = 960 mm/min ap = 2 mm ae = 24 mm Application: Grooving Coolant: Air Machine: Horizontal M/C, BT40 |

Standard cutting conditions

Size 07 inserts

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

| Carbon steel SS400, S15C, etc. E275A, C15E4, etc. |

– 200 HB | First choice | AH3225 | 100 – 250 | 0.07 – 0.2 | |

| – 200 HB | For fracture resistance | AH3135 | 100 – 250 | 0.07 – 0.2 | ||

| High Carbon steel, Alloy steel S45C, SCM440, etc. C45, 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 230 | 0.07 – 0.15 | |

| – 300 HB | For fracture resistance | AH3135 | 100 – 230 | 0.07 – 0.15 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 180 | 0.07 – 0.15 | |

| 30 – 40 HRC | For fracture resistance | AH3135 | 100 – 180 | 0.07 – 0.15 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | 90 – 200 | 0.07 – 0.15 | |

| – | For wear resistance | AH3225 | 90 – 200 | 0.07 – 0.15 | ||

| Grey cast iron FC250, etc. GG25, etc., 250, etc. |

150 – 250 HB | First choice | AH120 | 140 – 250 | 0.07 – 0.2 | |

| 150 – 250 HB | For fracture resistance | AH3225 | 140 – 250 | 0.07 – 0.2 | ||

| Ductile cast iron FCD450, etc. GGG45, etc., 450-10S, etc. |

150 – 250 HB | First choice | AH120 | 110 – 200 | 0.07 – 0.15 | |

| 150 – 250 HB | For fracture resistance | AH3225 | 110 – 200 | 0.07 – 0.15 | ||

| Titanium alloys Ti-6Al-4V, etc. |

– | First choice | AH3135 | 20 – 60 | 0.07 – 0.15 | |

| Heat-resistant alloys Inconel 718, etc. |

– | First choice | AH120 | 20 – 40 | 0.07 – 0.1 |

Size 12 inserts

| ISO | Workpiece material | Hardness | Priority | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

| Carbon steel SS400, S15C, etc. E275A, C15E4, etc. |

– 200 HB | First choice | AH3225 | MJ | 100 – 250 | 0.08 – 0.3 | |

| – 200 HB | For fracture resistance | AH3135 | MJ | 100 – 250 | 0.08 – 0.3 | ||

| – 200 HB | For wear resistance | T3225 | MJ | 100 – 300 | 0.08 – 0.3 | ||

| – 200 HB | Low cutting force | AH3225 | NMJ | 100 – 250 | 0.08 – 0.14 | ||

| High Carbon steel, Alloy steel S45C, SCM440, etc. C45, 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | MJ | 100 – 230 | 0.08 – 0.3 | |

| – 300 HB | For fracture resistance | AH3135 | MJ | 100 – 230 | 0.08 – 0.3 | ||

| – 300 HB | For wear resistance | T3225 | MJ | 100 – 280 | 0.08 – 0.3 | ||

| – 300 HB | Low cutting force | AH3225 | NMJ | 100 – 230 | 0.08 – 0.14 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 180 | 0.08 – 0.25 | |

| 30 – 40 HRC | For fracture resistance | AH3135 | MJ | 100 – 180 | 0.08 – 0.25 | ||

| 30 – 40 HRC | For wear resistance | T3225 | MJ | 100 – 200 | 0.08 – 0.25 | ||

| 30 – 40 HRC | Low cutting force | AH3225 | NMJ | 100 – 180 | 0.08 – 0.14 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | MJ | 90 – 200 | 0.08 – 0.25 | |

| – | For wear resistance | T3225 | MJ | 90 – 250 | 0.08 – 0.25 | ||

| – | Low cutting force | AH3135 | NMJ | 90 – 200 | 0.08 – 0.14 | ||

| Grey cast iron FC250, etc. GG25, etc., 250, etc. |

150 – 250 HB | First choice | AH8015 | MJ | 140 – 250 | 0.08 – 0.3 | |

| 150 – 250 HB | For fracture resistance | AH3225 | MJ | 140 – 250 | 0.08 – 0.3 | ||

| 150 – 250 HB | For wear resistance | T1215 | MJ | 140 – 300 | 0.08 – 0.3 | ||

| 150 – 250 HB | Low cutting force | AH8015 | NMJ | 140 – 250 | 0.08 – 0.14 | ||

| Ductile cast iron FCD450, etc. GGG45, etc., 450-10S, etc. |

150 – 250 HB | First choice | AH8015 | MJ | 110 – 200 | 0.08 – 0.25 | |

| 150 – 250 HB | For fracture resistance | AH3225 | MJ | 110 – 200 | 0.08 – 0.25 | ||

| 150 – 250 HB | For wear resistance | T1215 | MJ | 110 – 250 | 0.08 – 0.25 | ||

| 150 – 250 HB | Low cutting force | AH8015 | NMJ | 110 – 200 | 0.08 – 0.14 | ||

| Titanium alloys Ti-6Al-4V, etc. |

– | First choice | AH3135 | MJ | 20 – 60 | 0.08 – 0.2 | |

| – | Low cutting force | AH3135 | NMJ | 20 – 60 | 0.08 – 0.14 | ||

| Heat-resistant alloys Inconel 718, etc. |

– | First choice | AH8015 | MJ | 20 – 40 | 0.07 – 0.18 | |

| – | Low cutting force | AH8015 | NMJ | 20 – 40 | 0.07 – 0.14 |

Note: For NMJ chipbreaker, use a feed rate that satisfi es the following theoretical chip thickness:

| Designation | Chip thickness (mm) |

| TNMU120708PER-NMJ | < 0.2 |

For more information about this product, visit our online e-catalog or download the product report: