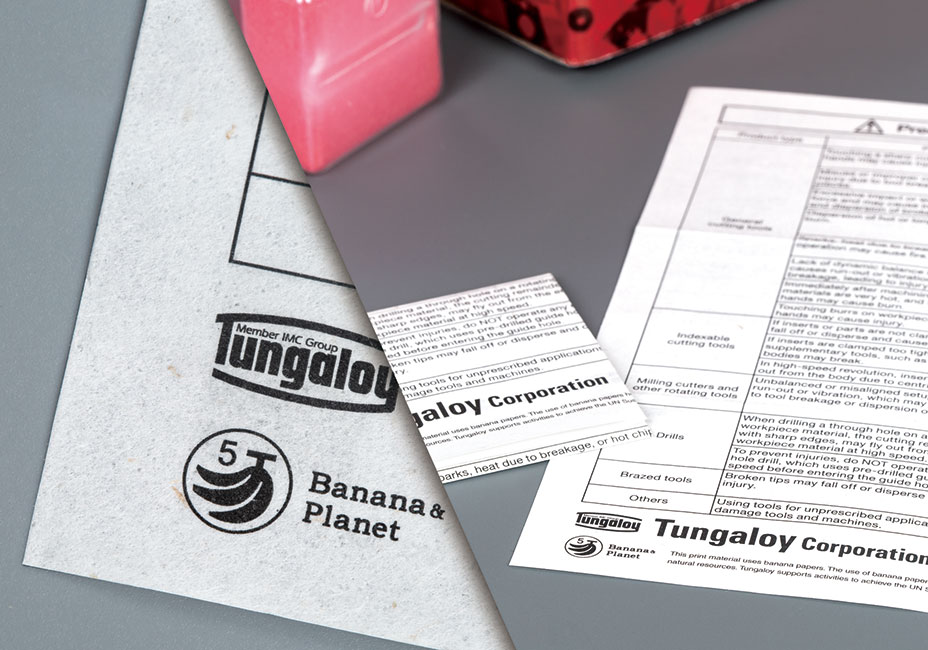

Collaboration of Japan’s traditional papermaking technology and banana stems creates one-of-a-kind precaution notes for customers

Tungaloy prints over 400,000 “Precautions on Cutting Tools” in a year to present our customers important warnings regarding tools. These notes are enclosed with all of our products except for inserts and few items. Starting from July 2022, all the paper currently used for the precaution notes will be replaced with banana papers.

Banana papers are made of unnecessary organic banana stems generated in the process of raising bananas in underdeveloped countries. In general, it takes 10 to 20 years for a tree to grow and mature, but banana trees start to produce fruits within a year of planting or cutting. Since old banana stems are usually eliminated and thrown away to bear good fruits, a large number of stems go to waste while growing bananas.

Japan has a long history of making papers, and a Japanese company succeeded to produce fine papers using these banana stems. What used to be thrown away could now be used for manufacturing papers, thereby contributing to environmental conservation. Also, the process of preparing banana stems for banana papers creates jobs in underdeveloped countries. In fact, the use of banana papers contributes to all categories of Sustainable Development Goals (SDGs).

You can see the banana stem residue in banana papers, so each precaution note is unique in its design. Tungaloy will continue supporting SDGs as well as offering our customers one-of-a-kind tooling solutions that help maximize productivity.

Click on the below link to view our latest Environmental Report:

https://tungaloy.com/wpdata/wp-content/uploads/environmental_report.pdf