Latest grade series for stainless steel turning with exceptional reliability

Latest grade series that provide solutions for all your machining challenges in stainless steel

Applications & Features

Applications

Features

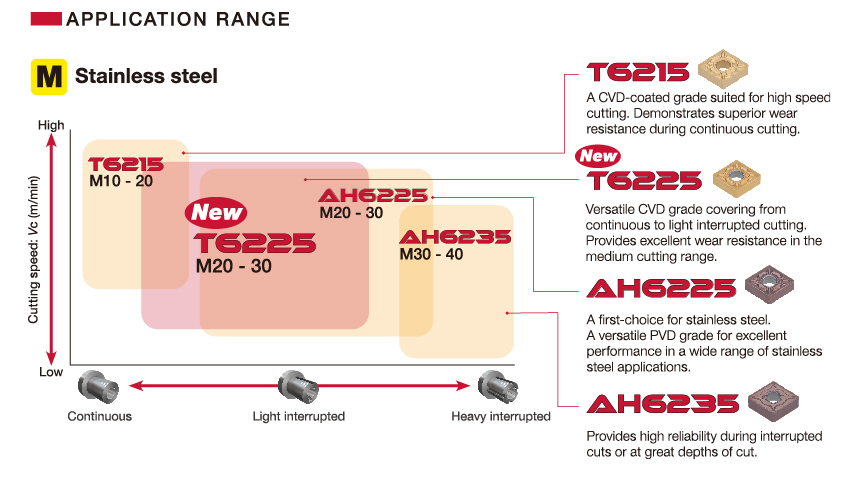

1. Application range

2. Grade feature

Versatile PVD-coated grade

Ti-enriched coating

– Thick Ti-enriched PVD coating for enhanced thermal shock resistance

– Reduced crater wear

High Ti-content nano-structured multilayer coating

The outer layer consists of a high Ti-content nano-structured multilayer made possible by Tungaloy’s latest coating technology. Its high hardness and nano structure provides the grade with a good balance of wear and fracture resistance, enhancing tool life and predictability.

Superior wear resistance

Enhanced hardness of outer layer

– Hard outer layer coating significantly reduces flank wear.

Strong adhesion of Al2O3 layers

– Tungaloy’s latest Al2O3 coating technology enhances the grade’s adhesion of coating, preventing edge chipping and coating delamination.

Thick coating

– 30% thicker than conventional grades.

– Provides superior wear resistance and long tool life.

Grades

T6215

![]()

![]()

-

P10 – P30 / M10 – M30

- Demonstrates excellent wear resistance for high speed continuous stainless steel cuts

AH6225

![]()

![]()

- P20 – P30 / M20 – M30

- First choice for stainless steel

- Excellent versatility for stainless steel machining, demonstrates a good combination of wear and fracture resistance

AH6235

![]()

![]()

- P30 – P40 / M30 – M40

- Demonstrates superior fracture resistance in stainless steel

- Provides high reliability for interrupted cuts and heavy-duty machining

Practical examples

Example #1

| Part: | Pipe part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | DNMG150408-SM |

| Grade: | T6215 |

| Cutting conditions: | Vc = 150(m/min) f = 0.3 (mm/rev) ap = 3 (mm) Application: External turning Coolant: Wet |

Example #2

| Part: | Machine part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | TNMG160408-SM |

| Grade: | T6215 |

| Cutting conditions: | Vc = 200(m/min) f = 0.3 (mm/rev) ap = 2.5 (mm) Application: External face turning Coolant: Wet |

Example #3

| Part: | Generator part |

| Material: | SUS410 / X12Cr13 |

| Insert: | CNMG120408-SH |

| Grade: | AH6235 |

| Cutting conditions: | Vc = 70 (m/min) f = 0.15 (mm/rev) ap = 2 – 4 (mm) Application: Face turning (interrupted cutting) Coolant: Wet |

Example #4

| Part: | Machine part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | CNMG120412-SM |

| Grade: | AH6235 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.2 (mm/rev) ap = 1.5 (mm) Application: Face turning (interrupted cutting) Coolant: Wet |

Example #5

| Part: | Joint part |

| Material: | SUS304 / X5CrNi18-9 |

| Insert: | CNMG120404-SM |

| Grade: | AH6225 |

| Cutting conditions: | Vc = 90(m/min) f = 0.2 (mm/rev) ap = 1 (mm) Application: External turning Coolant: Wet |

Example #6

| Part: | Machine part |

| Material: | SUS440 (Martensite stainless steel) |

| Insert: | VNMG160404-SF |

| Grade: | AH6225 |

| Cutting conditions: | Vc = 110 (m/min) f = 0.1 (mm/rev) ap = 0.5 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

Negative inserts

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Austenitic stainless steel |

Ferritic / martensite stainless steel |

Precipitation hardened stainless steel |

||||||

|

Finishing | SF | T6215 | 0.5 – 2.5 | 0.08 – 0.45 | 140 – 240 | 160 – 280 | 80 – 150 |

| T6225 | 0.5 – 2.5 | 0.08 – 0.45 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6225 | 0.5 – 2.5 | 0.08 – 0.45 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.5 – 2.5 | 0.08 – 0.45 | 50 – 150 | 70 – 170 | – | |||

| Medium cutting | SM | T6215 | 1 – 4 | 0.2 – 0.5 | 140 – 240 | 160 – 280 | 80 – 150 | |

| T6225 | 1 – 4 | 0.2 – 0.5 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6225 | 1 – 4 | 0.2 – 0.5 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 4 | 0.2 – 0.5 | 50 – 150 | 70 – 170 | – | |||

| SDM | T6215 | 1 – 4 | 0.2 – 0.5 | 140 – 240 | 160 – 280 | 80 – 150 | ||

| AH6225 | 1 – 4 | 0.2 – 0.5 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 4 | 0.2 – 0.5 | 50 – 150 | 70 – 170 | – | |||

| Heavy cutting | SH | T6215 | 2 – 6 | 0.3 – 0.6 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 2 – 6 | 0.3 – 0.6 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 2 – 6 | 0.3 – 0.6 | 50 – 150 | 70 – 170 | – | |||

PSS / PS / PM

| ISO | Operation | Chipbreaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Austenitic stainless steel |

Ferritic / martensite stainless steel | Precipitation hardened stainless steel | ||||||

|

Finishing | PSS | T6215 | 0.3 – 2 | 0.08 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 |

| AH6225 | 0.3 – 2 | 0.08 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.3 – 2 | 0.08 – 0.3 | 50 – 150 | 70 – 170 | – | |||

| Finishing to medium cutting |

PS | T6215 | 0.5 – 2.5 | 0.08 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 0.5 – 2.5 | 0.08 – 0.3 | 50 – 150 | 70 – 170 | – | |||

| Medium cutting | PM | T6215 | 1 – 3 | 0.15 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 1 – 3 | 0.15 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| AH6235 | 1 – 3 | 0.15 – 0.3 | 50 – 150 | 70 – 170 | – | |||

JS chipbreaker

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feedf (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| RE < 0.05 | RE < 0.1 | RE < 0.2 | RE < 0.4 | ||||||

|

Austenitic stainless steel | JS | AH6225 | 90 – 200 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 |

| Ferritic / martensite stainless steel | JS | AH6225 | 110 – 240 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | |

| Precipitation hardened stainless steel | JS | AH6225 | 60 – 110 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | |

For more information about this product, visit our online e-catalog or download the product report: