Multi-functional system for diverse grooving needs

TungCut has a wide selection of standard items; inserts and toolholders are applicable for all grooving operations

Applications & Features

Applications

Features

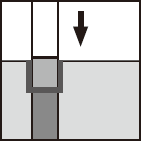

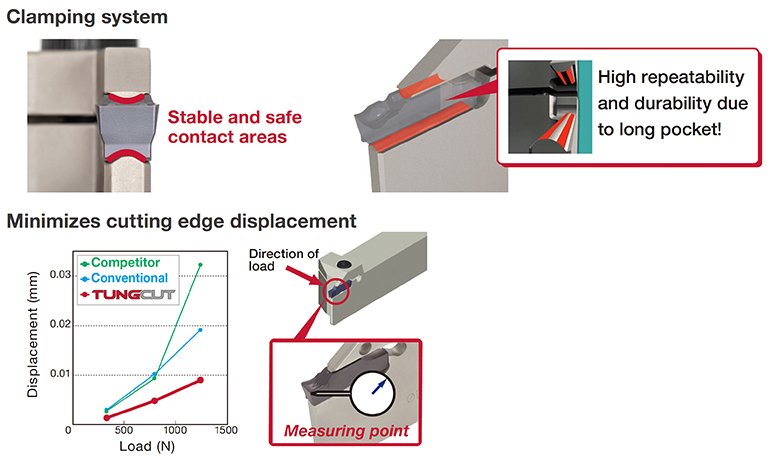

1. High clamping rigidity

For stable tool life and accuracy.

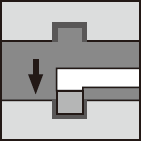

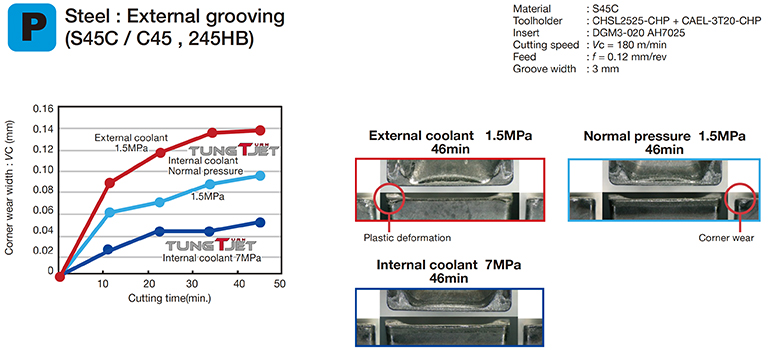

2. Benefits of TungTurn-Jet high pressure coolant supply

Drastically improved tool life.

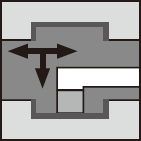

3. Chip breaker for grooving and turning

Inserts & Grades

Inserts

TungCut Inserts for External Grooving, Turning and Parting-off

- CW = 1.0 – 8.0 mm (.039″ – .315″)

TungCut & TungShortCut Inserts for Undercutting and Profiling

- CW = 1.85 – 8.0 mm (.073″ – .315″)

TungCut & TungShortCut Inserts for Internal Grooving and Turning

- CW = 0.8 – 8.0 mm (.031″ – .315″)

TungCut Inserts for Face Grooving and Turning

- CW = 1.2 – 8.0 mm (.047″ – .315″)

TungCut CBN Inserts for Grooving and Turning

- CW = 2.0 – 5.0 mm (.079″ – .197″)

TungCut PCD Inserts for Grooving and Turning

- CW = 2.0 – 5.0 mm (.079″ – .197″)

Main Grades

AH7025

![]()

![]()

![]()

- P20 – P30 / M20 – M30 / S15 – S25

- Excellent wear resistance and high rigidity

- First choice for grooving of various materials

T9225

![]()

- P15 – P25

- First choice for roughing to medium cutting

- High fracture resistance

BX360

![]()

- Suitable for general machining of hardened steel

Toolholders

Grooving, Turning & Parting

TungCut Toolholders

Multi-functional system for diverse grooving needs

Internal Grooving & Turning

TungShortCut Toolholders

Toolholder that accommodates downsized internal grooving insert

Other

TungCut Tool Blocks, Shanks

Multi-functional system for diverse grooving needs

Other

Practical examples

Example #1

Miniature / Electronic Industry

| Part: | Ring encoder |

| Material: | SUM22L |

| Toolholder: | CTER2020-4T25 |

| Insert: | DGM4-030 |

| Grade: | AH7025 |

| Cutting conditions: | Vc = 180 (m/min) f = 0.2 (mm/rev) CW = 4 (mm/min) CDX = 8 (mm) Application: Parting off Coolant: Wet |

Example #2

General Engineering

| Part: | Gear Housing |

| Material: | SCM420 / 20Cr4 |

| Toolholder: | CTER2525-3T09 |

| Insert: | DTX3-030 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 120 (m/min) f = 0.15 (mm/rev) CW = 3 (mm) CDX = 7 (mm) Application: Grooving Coolant: Wet |

Example #3

General Engineering

| Part: | Valve |

| Material: | SUS304 / X5CrNi18-9 |

| Toolholder: | CTIR25-3T05-D250 |

| Insert: | DTX3-030 |

| Grade: | AH7025 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.08 (mm/rev) CW = 3 (mm) CDX = 2.2 (mm) Application: Grooving Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

|

Steel S45C, SCM435, etc. C45, 34CrMo4, etc. |

< 300 HB | First choice | AH7025, AH725 | 50 – 180 |

| < 300 HB | Wear resistance | T9225, AH8005 | 80 – 300 | ||

| < 300 HB | Impact resistance | AH6235,GH130 | 50 – 120 | ||

| < 300 HB | Surface quality | NS9530 | 80 – 220 | ||

|

Stainless steel SUS303, SUS304, etc. X10CrNiS18-9, X5CrNi18-9, etc. |

< 200 HB | First choice | AH7025, AH725 | 50 – 120 |

| < 200 HB | Wear resistance | AH8005 | 50 – 120 | ||

| < 200 HB | Impact resistance | AH6235,GH130 | 50 – 120 | ||

|

Grey cast iron FC250, etc. 250, etc. |

– | First choice | T515 | 150 – 700 |

| – | Impact resistance | AH8005, AH7025, AH6235, GH130 | 50 – 180 | ||

| Ductile cast iron FCD450, etc. 450-10S, etc. |

– | First choice | T515 | 150 – 300 | |

| – | Impact resistance | AH8005, AH7025, AH6235, GH130 | 50 – 120 | ||

|

Aluminium alloys Si < 12% |

– | First choice | TH10 | 100 – 500 |

| – | First choice | KS05F | 100 – 600 | ||

|

Superalloys Inconel718, etc. |

< HRC 40 | First choice | AH8005 | 20 – 60 |

| < HRC 40 | Impact resistance | AH7025, AH725, AH6235 | 20 – 40 | ||

| Titanium alloys Ti-6Al-4V, etc. |

< HRC 40 | First choice | KS05F | 20 – 100 | |

| < HRC 40 | Impact resistance | AH7025, AH725 | 20 – 80 |

DTV

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

AH7025 | 50 – 180 | 0.05 – 0.3 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

AH7025 | 50 – 180 | 0.05 – 0.3 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

AH7025 | 50 – 120 | 0.05 – 0.3 |

|

Grey cast iron FC250, etc. 250, etc. |

AH7025 | 50 – 180 | 0.05 – 0.3 |

| Ductile cast iron FCD450, etc. 450-10S, etc. |

AH7025 | 50 – 120 | 0.05 – 0.3 | |

|

Titanium alloys Ti-6AI-4V, etc. |

AH7025 | 20 – 80 | 0.05 – 0.3 |

| Superalloys Inconel718, etc. |

AH7025 | 20 – 80 | 0.05 – 0.3 |

STV*S

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

AH725 | 50 – 180 | 0.05 – 0.1 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

AH725 | 50 – 180 | 0.05 – 0.1 | |

|

Stainless steels SUS304, etc. X5CrNi18-9, etc. |

AH725 | 50 – 120 | 0.05 – 0.1 |

|

Grey cast iron FC250, etc. 250, etc. |

AH725 | 50 – 180 | 0.05 – 0.1 |

| Ductile cast iron FCD450, etc. 450-10S, etc. |

AH725 | 50 – 120 | 0.05 – 0.1 | |

|

Superalloys Inconel718, etc. |

AH725 | 20 – 80 | 0.05 – 0.1 |

| Titanium alloys Ti-6AI-4V, etc. |

AH725 | 20 – 80 | 0.05 – 0.1 |

STX

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

|

External grooving | > 50 HRC | First choice | BX360 | 80 – 150 |

| Groove wall cutting | |||||

| Side turning | |||||

| Internal grooving | > 50 HRC | First choice | BX360 | 80 – 120 | |

| Face grooving |

| ISO | Workpiece material | Grade | Operation | Cutting speed Vc (m/min) |

Feed f(mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|

|

Aluminium alloys Si ≦ 12% |

DX160 | Grooving | 200 – 2000 | 0.05 – 0.15 | – |

| DX160 | Turning | 200 – 2000 | 0.07 – 0.3 | < 1 | ||

| Aluminium alloys Si ≧ 12% |

DX160 | Grooving | 200 – 1500 | 0.05 – 0.15 | – | |

| DX160 | Turning | 200 – 1500 | 0.07 – 0.3 | < 1 | ||

| Copper and copper alloys | DX160 | Grooving | 200 – 1500 | 0.05 – 0.15 | – | |

| DX160 | Turning | 200 – 1500 | 0.07 – 0.3 | < 1 | ||

| Carbon / Graphites | DX160 | Grooving | 200 – 500 | 0.05 – 0.15 | – | |

| DX160 | Turning | 200 – 500 | 0.07 – 0.3 | < 1 | ||

| Ceramic | DX160 | Grooving | 100 – 200 | 0.02 – 0.1 | – | |

| DX160 | Turning | 100 – 200 | 0.02 – 0.1 | < 1 | ||

| Tungsten carbide(HRA80 – 95) | DX160 | Grooving | 5 – 30 | 0.02 – 0.1 | – | |

| DX160 | Turning | 5 – 30 | 0.02 – 0.1 | 0.02 – 0.2 |

SGN

| ISO | Grade | Edge preparation | Workpiece condition | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|---|

|

BX360 | No symbol | Continuous | 80 – 150 | 0.03 – 0.08 |

| -S | Light interrupted | 50 – 120 | 0.03 – 0.08 | ||

| -H | Heavy interrupted | 40 – 100 | 0.03 – 0.06 |

STR

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

|

External profiling | > 50 HRC | First choice | BXA10 | 80 – 180 |

STH

| ISO | Grade | CW | Application | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|---|---|

|

BXA10 | 3 | External turning | 100 – 230 | 0.08 – 0.12 | 0.4 – 1 |

| Face turning | 100 – 230 | 0.08 – 0.12 | 0.4 – 0.8 | |||

| 5 | External turning | 100 – 230 | 0.08 – 0.12 | 0.5 – 1.5 | ||

| Face turning | 100 – 230 | 0.08 – 0.12 | 0.5 – 0.8 |

For more information about this product, visit our online e-catalog or download the product report: