Iwaki, Japan – October, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungCut series, now featuring external coolant-type face grooving adapters and 32×32 mm square shanks for improved chip control, machining stability, and compatibility with large lathes.

Challenges and Trends

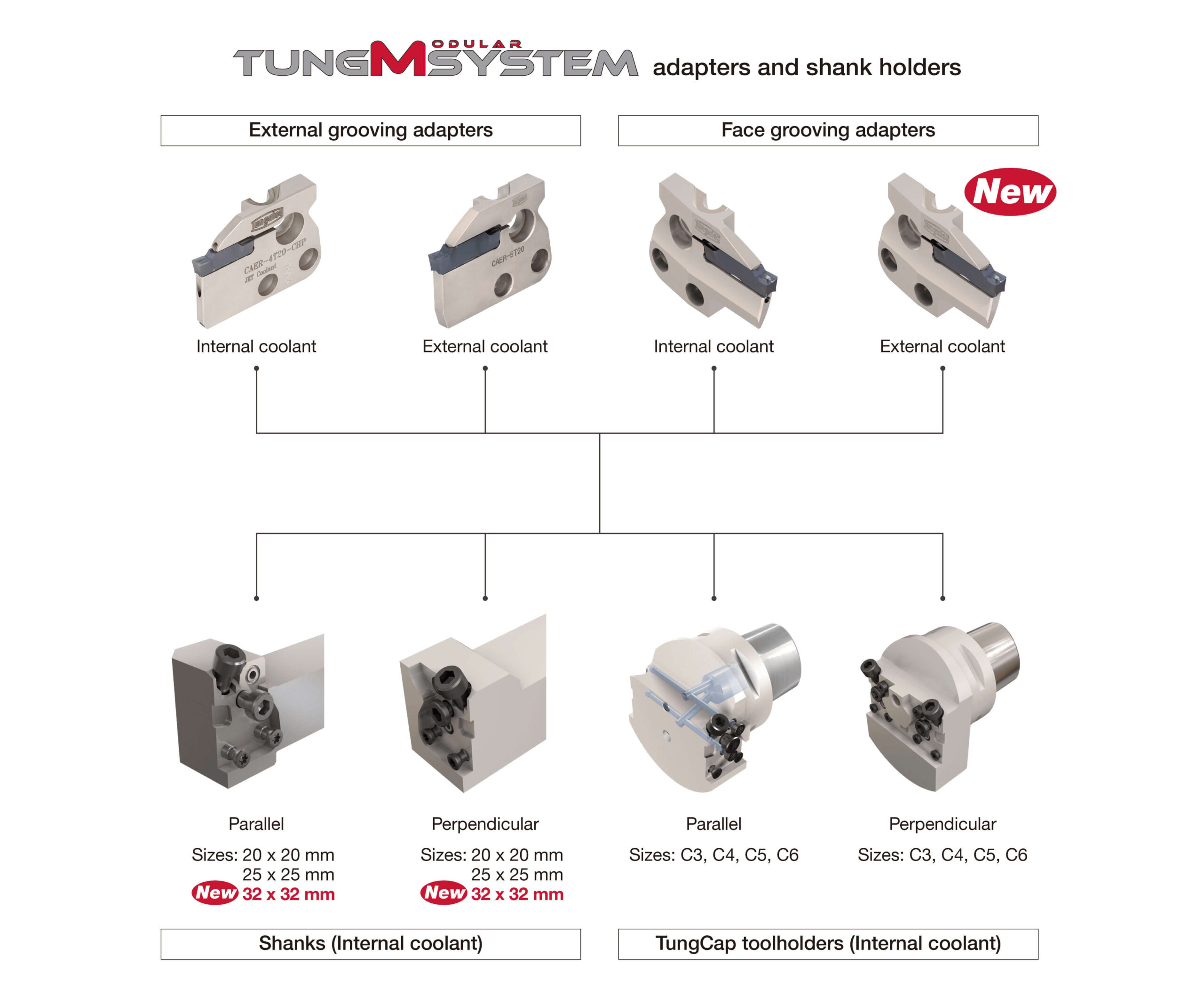

Due to previous limitations, the TungModularSystem’s face grooving adapters were only available with internal coolant supply, posing a cost barrier for users operating with external coolant systems as they required additional equipment or modifications during implementation. Additionally, the 32×32 mm square shank specification was only available as a special order, making it difficult for facilities using 32×32 mm machines to adopt the system. As a result of these challenges, many users continued using the initial TungCut specification. These Challenges and Market Conditions created a strong demand for a more flexible and cost-effective solution.

Product Overview

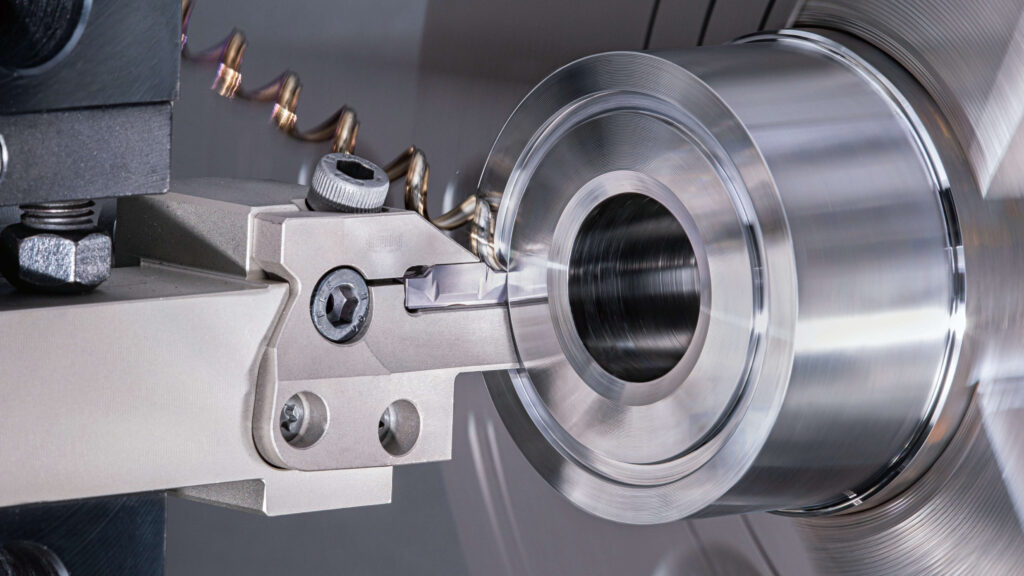

TungCut is a high-rigidity tool series designed for grooving and parting operations. It delivers excellent surface finish even at high feed rates and adapts to a wide range of workpiece shapes and machining conditions. The system ensures stable chip control and high-precision machining.

Benefits and Features

Feature 1: Improved Chip Control with Expanded Lineup of External Coolant-Fed Face Adapters

- The addition of external coolant-fed face adapters significantly reduces the risk of chip entanglement, even in face grooving operations where chips tend to become stringy.

- Prevents chip intrusion into the coolant holes, a common issue when using internal coolant adapters with external coolant setups.

- Meets the needs of users employing external coolant systems by providing a more stable machining environment.

Feature 2: Stable Machining through TungModularSystem’s High-Rigidity Clamping Mechanism

- Newly designed clamping mechanism enhances the rigidity of the adapter, suppressing vibration and deflection.

- High rigidity contributes to extended tool life and improved surface finish.

- A common shank design allows the use of both internal and external coolant adapters with the same shank.

Feature 3: Expanded Compatibility with Large Lathes through Addition of 32×32 mm Square Shank

- Standardizing the 32×32 mm square shank, commonly used for large workpiece machining, enhances compatibility with heavy-duty lathes.

- Enables direct mounting on lathes without jigs, reducing setup time.

- Accommodates a wide range of machine environments, improving overall user convenience.