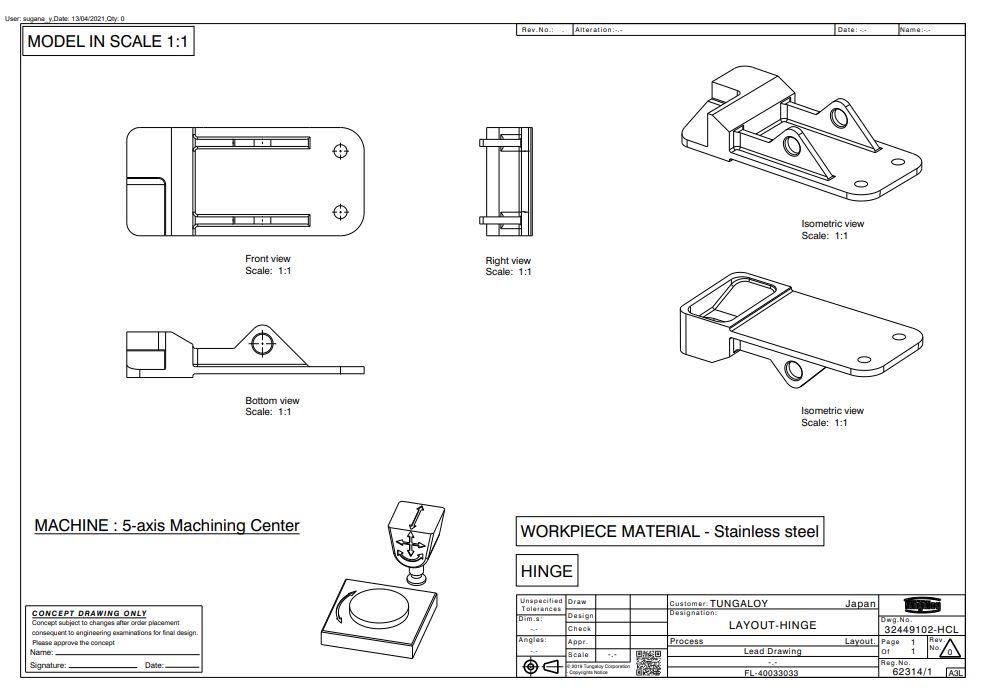

Aerospace – Hinge

The internal structure of an aircraft is composed of many beams and various structural elements. Hinges and brackets are used to support these structures at various parts and places of the airframe, making them components that bear high loads. In order to ensure performance that can withstand the loads generated during flight, the construction of an optimal machining process to meet the high quality demands is considered crucial. Tungaloy is committed to offering comprehensive machining solutions that respond to the high quality demands of aircraft structural components, while also enhancing production efficiency.

Tooling concepts

- Improving machining efficiency and suppressing chatter tendencies in thin-walled parts.

- Proposing applications that ensure stable machining quality while achieving high productivity.

- Maximizing the performance of 5-axis machining centers by applying cutting tools with multifunctionality, including ramping and contouring.

Featured process

- Demonstrates high wear and chipping resistance in the machining of Titanium alloy or heat-resistant alloys

- Remarkable reliability in wet machining

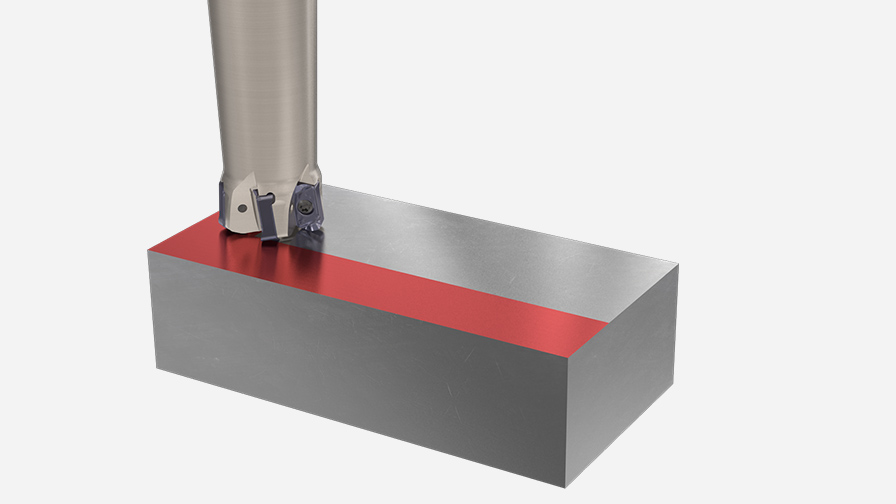

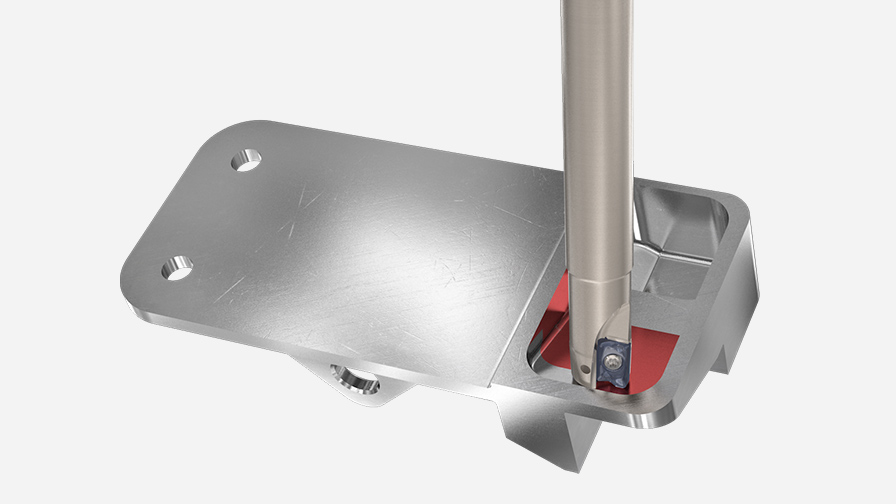

Process 2: Finish Face & Shoulder Milling

Benefits

- The VEH head of TungMeister features unequal pitch and lead specifications, excelling in resistance to chatter.

- Ensures machining surface quality even in finishing operations of stainless steel, which is prone to chatter due to its high specific cutting resistance.

![]()

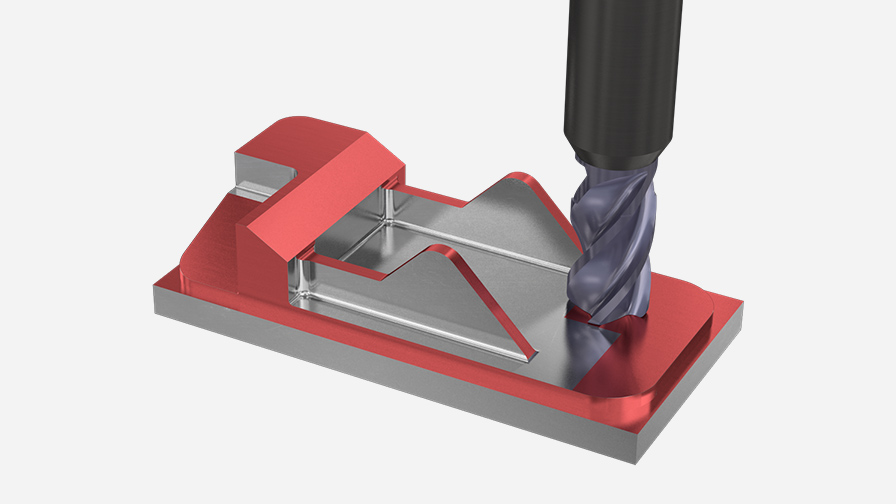

VEH head

- The VEH head features unequal lead and unequal pitch, offering excellent resistance to chatter.

- By suppressing chatter, it enhances the quality of machined surfaces and extends tool life.

- Indexable high-feed milling cutter, available in as small as ø8 mm diameter, offers free cutting and effective chip control in a wide range of applications

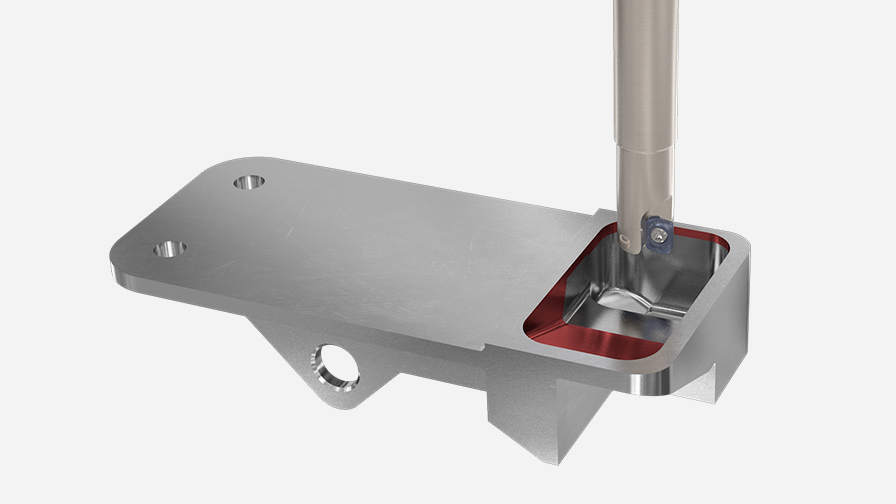

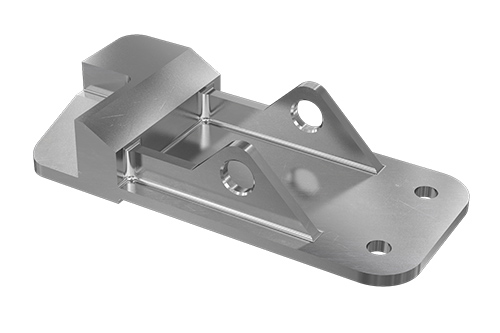

Process 4: Finish Face & Shoulder Milling

Benefits

- TungForce-Rec is a shoulder milling cutter that employs featuring unique V-shaped bottom-face inserts.

- The distinctive V-shaped bottom-face inserts allow for a larger core thickness in the body, resulting in high body rigidity.

- The unique cutting edge design and high body rigidity enable achieving wall accuracy close to that of solid end mills.

- Demonstrates high wear and chipping resistance in the machining of Sustainless Stainless steel.

- Remarkable reliability in wet machining