Applications & Features

Inserts & Grades

Inserts

Grades

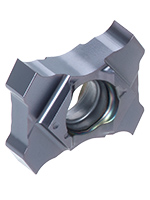

AH725

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Toolholders

Practical examples

Example #1

| Part: | Adapter |

| Material: | SUM23 (Free alloy steel) |

| Toolholder: | A12H-STCIR10-D105 |

| Insert: | TCIG10-200-010 |

| Grade: | AH725 |

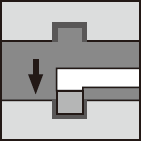

| Cutting conditions: | Vc = 50 (m/min) f = 0.05 (mm/rev) CW = 2 (mm) CDX = 1 (mm) Application: Internal grooving Coolant: Wet |

Example #2

| Part: | Cylinder Head |

| Material: | S45C /C45 |

| Toolholder: | A12H-STCIR10-D120 |

| Insert: | TCIG10-200-010 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 90 (m/min) f = 0.05 (mm/rev) CW = 2 (mm) CDX = 8 (mm) Application: Internal grooving Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Priority | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|---|

| Steels S45C, C45, SCM435, 34CrMo4, etc. |

< 300 HB | First choice | 30-80 | 0.01-0.05 | |

| Stainless steel SUS303, X10CrNiS18-9, etc. |

< 200 HB | First choice | 30-50 | 0.01-0.05 | |

| Titanium alloys Ti-6Al-4V, etc. |

< HRC 40 | First choice | 10-50 | 0.01-0.05 |

For more information about this product, visit our online e-catalog or download the product report: