Stable parting-off operations due to unique clamping system

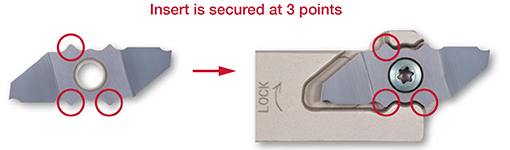

Innovative clamping system assures stability in parting off operations

Applications & Features

Applications

Features

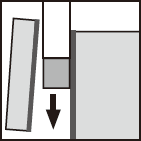

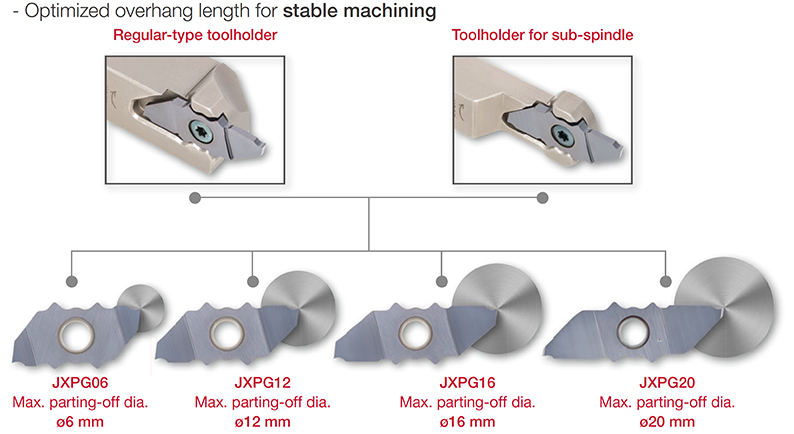

1. 4 types of inserts are available for various parting-off diameters and can be mounted in the same pocket of the toolholder

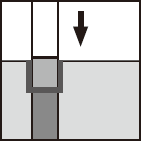

2. Unique clamping system for highly rigid clamping

Inserts & Grades

Inserts

DuoJust-Cut Grooving and Parting-off Inserts (Maximum parting-off dia. Ø20 mm)

- Rigid grooving and parting-off insert

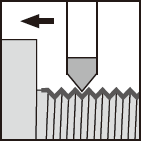

DuoJust-Cut Threading Inserts (Pitch 0.2 – 1.5 mm)

- Rigid threading insert

Grades

SH7025

![]()

![]()

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

DX110

![]()

- Excellent sharpness for high surface quality

- Suitable for fi nishing non-ferrous metal and nonmetal

Toolholders

Practical examples

Example #1

| Part: | Electric part |

| Material: | SUM23 |

| Toolholder: | JSXXR1212X09 |

| Insert: | JXPS12R08F |

| Grade: | SH725 |

| Cutting conditions: | Vc = 110 (m/min) f = 0.03 (mm/rev) CW = 0.8 (mm) Application: Parting-off Coolant: Wet |

Example #2

| Part: | Spool |

| Material: | A6061 |

| Toolholder: | JSXXR1212X09 |

| Insert: | JXDX12R20F |

| Grade: | DX110 |

| Cutting conditions: | Vc = 300 (m/min) f = 0.05 (mm/rev) CW = 5 (mm) Application: Grooving, Turning (in a single pass) Coolant: Wet |

Example #3

| Part: | Hydraulic component |

| Material: | SUS304 / X5CrNi18-9 |

| Toolholder: | JSXXL1212X09-S |

| Insert: | JXPG16L20F |

| Grade: | SH725 |

| Cutting conditions: | Vc = 75 (m/min) f = 0.02 (mm/rev) CW = 2.0 (mm) Application: Parting-off Coolant: Wet |

Standard cutting conditions

Parting, Grooving

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 SH7025 |

50 – 200 | 0.01 – 0.05 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 SH7025 |

50 – 200 | 0.01 – 0.05 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 SH7025 |

50 – 200 | 0.01 – 0.05 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 SH7025 |

50 – 200 | 0.01 – 0.05 |

|

Aluminium alloys A5056, A6061, etc. |

SH725 SH7025 |

150 – 200 | 0.01 – 0.05 |

| Copper alloys C2600, C280C, etc. |

SH725 SH7025 |

100 – 200 | 0.01 – 0.05 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 SH7025 |

30 – 80 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH725 SH7025 |

30 – 80 | 0.01 – 0.05 |

JXBM12R

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 150 | 0.02 – 0.15 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 150 | 0.02 – 0.15 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 150 | 0.02 – 0.15 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 30 – 120 | 0.02 – 0.12 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 100 – 150 | 0.02 – 0.15 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 150 | 0.02 – 0.15 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

For_aluminium_and_non-ferrous_metal_PCD_insert

| ISO | Workpiece materials | Grades | Operation | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|

|

Aluminium alloys A5056, A6061, etc. |

DX110 | Grooving | 100 – 300 | 0.03 – 0.15 | – |

| DX110 | Turning | 100 – 300 | 0.03 – 0.15 | < 6 |

Threading

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 SH7025 |

50 – 200 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 SH7025 |

50 – 200 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 SH7025 |

50 – 200 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 SH7025 |

50 – 200 |

|

Aluminium alloys A5056, A6061, etc. |

SH725 SH7025 |

150 – 200 |

| Copper alloy C2600, C280C, etc. |

SH725 SH7025 |

100 – 200 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 SH7025 |

30 – 80 |

| Superalloys Inconel718, etc. |

SH725 SH7025 |

30 – 80 |

For more information about this product, visit our online e-catalog or download the product report: