Indexable gun drill with exceptional efficiency

DeepTri-Drill, the easy-to-handle, indexable gundrill series, delivers outstanding performance, exceptional efficiency and stability in deep hole drilling.

Applications & Features

Applications

Features

1. Wide range of options for various deep hole applications

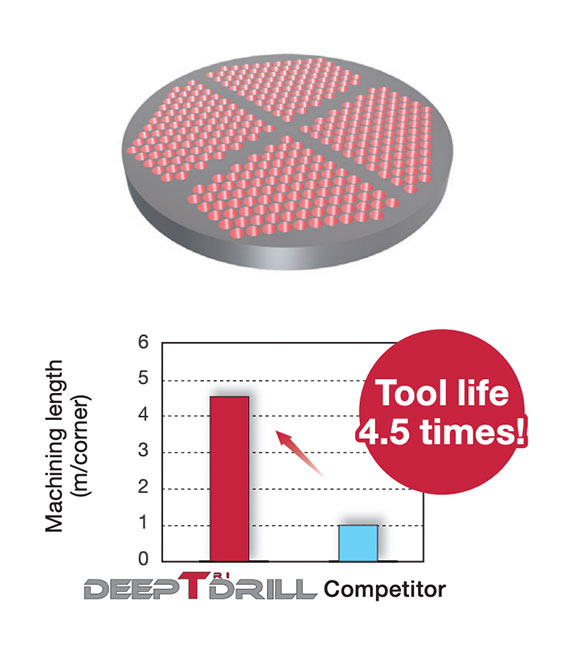

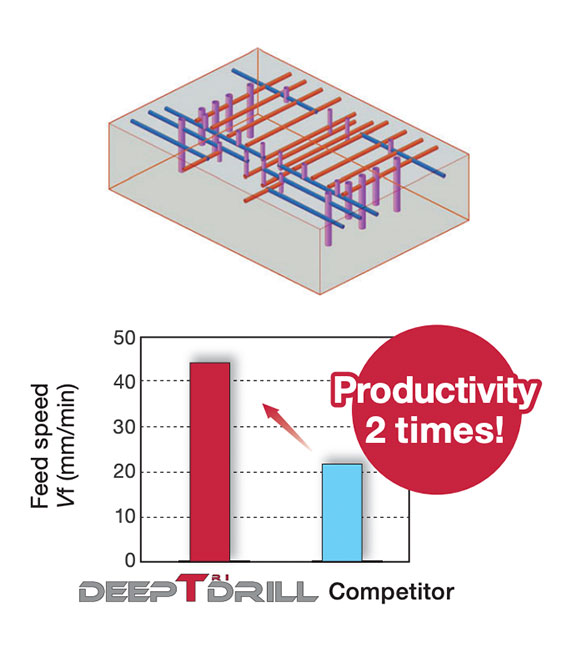

2. Ultimate efficiency

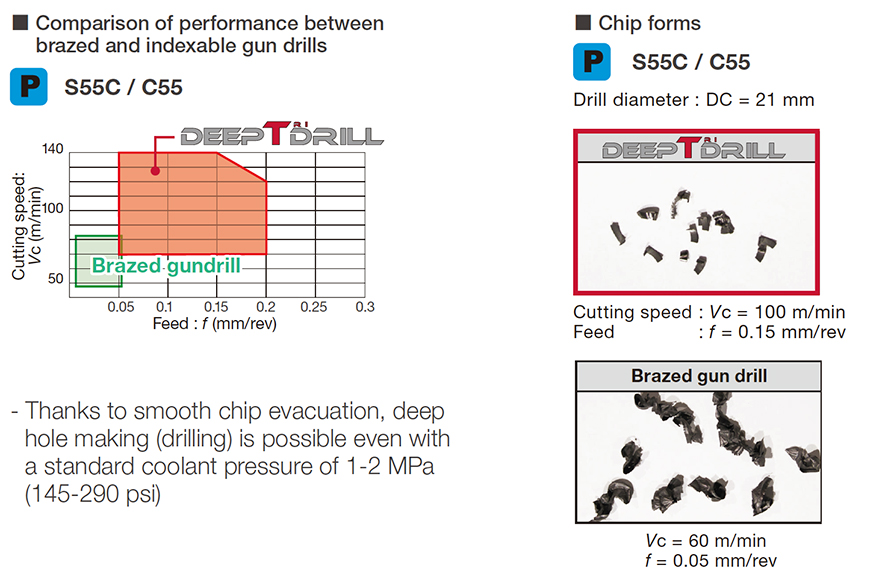

• Unique chip breaker and chip splitter on the cutting edge enables impressive chip control at any feed rate, especially at higher feeds

• Thanks to smooth chip evacuation, deep hole making (drilling) is possible even with a standard coolant pressure of 1-2 MPa (145-290 psi)

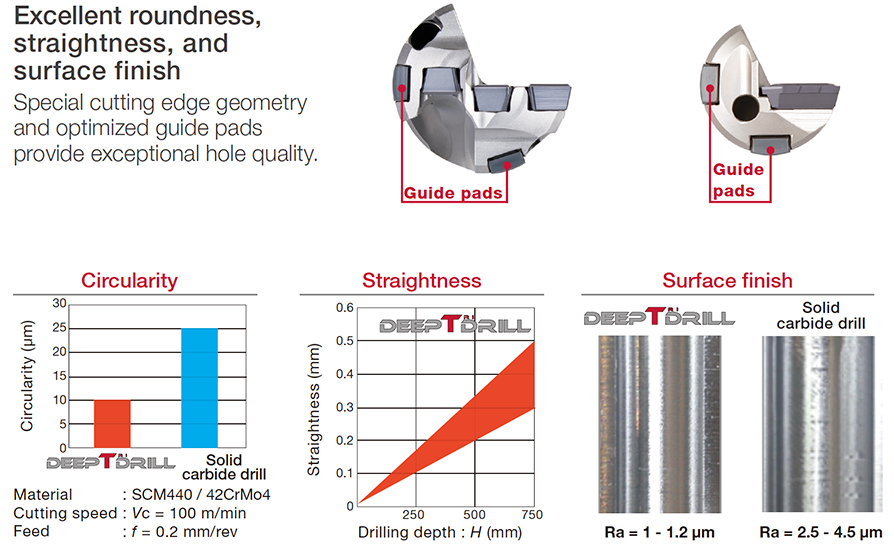

3. Excellent roundness, straightness, and surface finish

• Special cutting edge geometry and optimized guide pads provide exceptional hole quality.

Inserts & Grades

Inserts

TOHT-NDJ/NDL

- 3 cutting edges inserts with chip splitter

LOGT-NDJ

- 2 cutting edges inserts with chip splitter

ZSGT-NDJ

- Single sided insert with chip splitter

Main Grades

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- High wear resistance

- Designed for drilling various materials

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

FH3125 (For guide pads)

- First recommendation

- Long tool life due to unique substrate and coating

FH3135 (For guide pads)

- High fracture resistance

- First choice when using water-soluble coolant

Drill bodies

Practical examples

Example #1

Heat Exchanger Industry

| Part: | Tube Sheet |

| Material: | SUS304 / X5CrNi18-9 |

| Drill: | MCTR20.00XM32-10 |

| Insert: | TOHT090305R-NDL |

| Grade: | AH725 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.04 (mm/rev) Vf = 53 (mm/min) H = 200 (mm) Coolant: Wet Machine: Horizontal M/C |

Example #2

Die and Mold Industry

| Part: | Plastic mold |

| Material: | SKD61 / X40CrMoV5-1 (45 HRC) |

| Drill: | TRLGCH18.00X1500-36A |

| Insert: | TOHT080305R-NDJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 62 (m/min) f = 0.04 (mm/rev) Vf = 44 (mm/min) H = 700 (mm) Coolant: Wet Machine: Horizontal M/C |

Example #3

Automotive Industry

| Part: | Shaft |

| Material: | SCM420H |

| Drill: | MCTR12.00XM20-20 |

| Insert: | LOGT060204R-NDJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 150 (m/min) f = 0.13 (mm/rev) Vf = 517 (mm/min) øDc = 12 (mm) H = 233 (mm) Coolant: Wet Machine: Vertical M/C |

Standard cutting conditions

Drill diameter: DC = ø7.94 – ø9.99 mm

| ISO | Workpiece material | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feedf (mm/rev) |

|---|---|---|---|---|---|

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Grey cast iron FC250, GG25, 250, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Ductile cast iron FCD700, 700-2, etc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Aluminium alloys | NDJ | AH9130 | 60 – 100 | 0.05 – 0.18 | |

| Heat-resistant alloys Inconel 718, etc. |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | |

| Titanium alloys Ti-6Al-4V, etc. |

NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | |

| Hardened steel ≥ 40HRC |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 |

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø10 – ø28 mm

| ISO | Workpiece material | Priority | Chip-breaker | Grade | Cutting speed Vc (m/min) |

Feed:f (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| ø10 – ø11.8 | ø11.81 – ø13.99 | ø14 – ø18 | ø18.01 – ø28 | ||||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.12 | 0.08 – 0.1 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 80 – 120 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| First choice | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| First choice | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Aluminium alloys | Lower feed | NDL | AH725 | 80 – 160 | – | – | 0.03 – 0.15 | 0.03 – 0.15 | |

| First choice | NDJ | AH9130 | 100 – 200 | 0.05 – 0.18 | 0.05 – 0.2 | 0.08 – 0.22 | 0.1 – 0.25 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | NDL | AH725 | 20 – 50 | – | – | 0.03 – 0.06 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | NDL | AH725 | 30 – 60 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| First choice | NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.15 | ||

| Hardened steel ≥ 40HRC |

Lower feed | NDL | AH725 | 40 – 100 | – | – | 0.03 – 0.08 | 0.03 – 0.08 | |

| First choice | NDJ | AH9130 | 50 – 100 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

Drill diameter: DC = ø28.01 – ø40 mm

| ISO | Workpiece material | Priority | For central | For intermediate | For peripheral | Cutting speed Vc (m/min) |

Feedf (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Chip-breaker | Grade | Chip-breaker | Grade | Chip-breaker | Grade | ø28.01 – ø40 | ||||

| Low carbon steel (C < 0.3) SS400, SM490, S25C, etc. E275A, C25, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Carbon steel (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.3 | ||

| Low alloy steel (C < 0.3) SCM415, 18CrMo4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Alloy steel (C > 0.3) SCM440, SCr420, 42CrMo4, 20Cr4, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 120 | 0.1 – 0.3 | ||

| Stainless steel (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Martensitic, Ferritic) SUS430, SUS416, etc. X6Cr17, X12CrS13, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Stainless steel (Precipitation hardening) SUS630, X5CrNiCuNb16-4, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Grey cast iron FC250, GG25, 250, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Ductile cast iron FCD700, 700-2, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Aluminium alloys | Lower feed | G | AH725 | DL | AH725 | G | AH725 | 80 – 160 | 0.03 – 0.2 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 100 – 200 | 0.1 – 0.3 | ||

| Heat-resistant alloys Inconel 718, etc. |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 20 – 50 | 0.03 – 0.08 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 20 – 50 | 0.06 – 0.13 | ||

| Titanium alloys Ti-6Al-4V, etc. |

Lower feed | G | AH725 | DL | AH725 | G | AH725 | 30 – 60 | 0.03 – 0.1 | |

| First choice | G | AH725 | G | AH725 | G | AH725 | 30 – 60 | 0.1 – 0.18 | ||

| Hardened steel ≥ 40HRC |

Lower feed | G | AH8015 | DL | AH725 | G | AH725 | 40 – 100 | 0.03 – 0.1 | |

| First choice | G | AH8015 | G | AH8015 | G | AH8015 | 50 – 100 | 0.06 – 0.13 | ||

The use of NDL chipbreakers is recommended for cross hole drilling with low feed conditions.

*Coolant recommendations for drilling stainless steel:

– Oil coolant is first priority

– Water soluble coolant requires at least 20% oil concentration

For more information about this product, visit our online e-catalog or download the product report:

Metric

Drill body

Guide pad

Imperial

Drill body