Non-Ferrous Application Series

Complete turning solutions for non-ferrous materials

The ultimate tools for high speed machining of non-ferrous alloys.

Chip nesting is a thing of the past.

Applications & Features

Applications

Features

Ultra-fine grained PCD-tipped inserts

Definitive insert series for high speed machining of aluminum alloys

- Ultra-fine grained PCD grade for edge sharpness

- An extremely wear-resistant grade, featuring strongly-bonded diamond grains that prevents the grains from breaking off during machining

- Thanks to ultra-fine diamond grains, DX110 provides superior surface finish

- Chipbreaker series with rake angle of 10°

1. Grade selection guide

2. PCD grades and applications

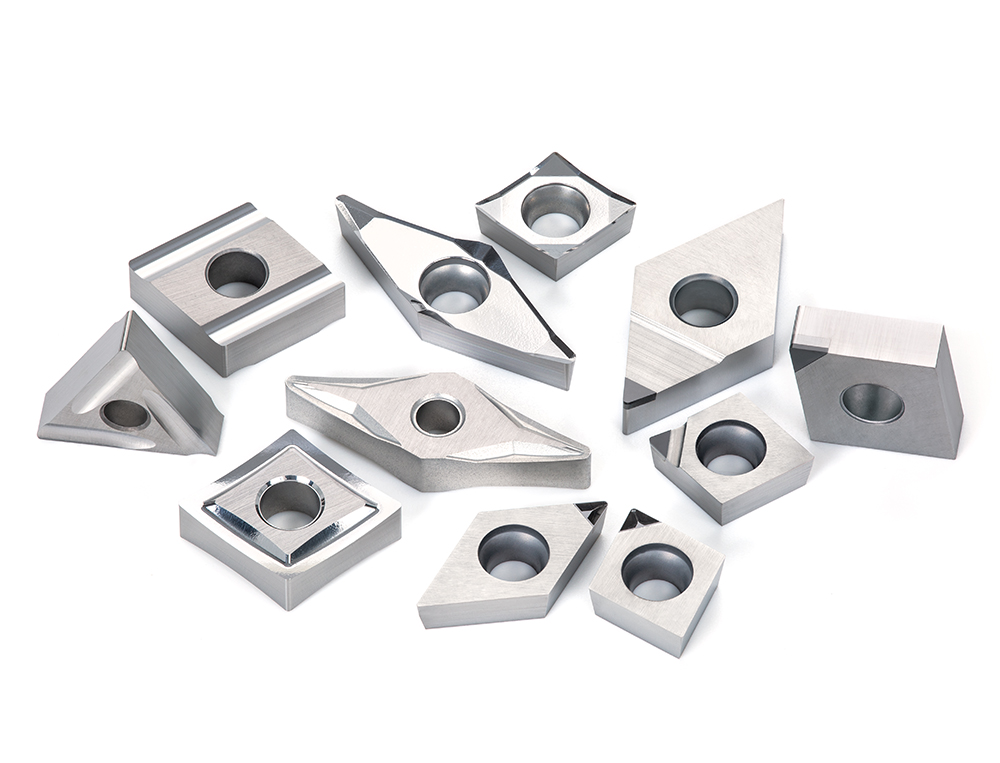

PCD inserts with 3D chipbreaker

No more chip nesting in aluminum alloy machining

Unique 3D chipbreaker

- Versatile geometry allows excellent chip control

- One insert handles from rough to finish operations

- Optimal rake angle design effectively directs chips to the redirector

Fine-grained cemented carbide inserts with chipbreaker for non-ferrous alloy

No more chip nesting in aluminum alloy and copper alloy machining

For positive insert

First-choice geometry for non-ferrous applications

AL

- Provides excellent chip control and resistance to wear and built-up edge

- Low cutting forces generated by a large rake angle and sharp cutting edge

- 3D geometry with lapped rake face

- Superb chip control enabled by large inclination angle of the cutting edge

- Available on 26 total inserts, including CCGT, DCGT, RCGT, TCGT, and VCGT inserts

For negative insert

Press-in chipbreaker ideal for medium to finish operations

28

- Versatile geometry with a large inclination angle of the cutting edge. Ideal for medium to finish operations

- Provides superior surface finish and chip control

Linear chipbreaker

P

Provides process security across a wide range of applications

DLC coated inserts

Tungaloy original DLC coating grade for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

Excellent built-up edge resistance and high surface quality

Excellent built-up edge resistance achieves high quality glossy machined surface.

Excellent wear resistance

The coating with high hardness and excellent heat resistance reduce wear progress.

Stable and reliable machining

Outstanding coating adhesion technology provides stable and reliable machining.

Grades

DX110

![]()

- Excellent sharpness for high surface quality

- Suitable for finishing non-ferrous metal and nonmetal

KS05F

![]()

- N15

- Uncoated cemented carbide

DX200

![]()

- 100% diamond grade

- DX200 has a sharp cutting edge that provides excellent surface finish.

DX160

![]()

- Designed for machining ceramic, cemented carbide, and nonmetal

DS2005

![]()

- Excellent wear resistance ensures stable long life in high-speed machining of non-ferrous metals.

DS2015

![]()

- Well balanced wear and chipping resistance perform stable and reliable machining in a wide range of machining applications.

Practical examples

Example #1

Automotive Industry

| Part: | Con-rods |

| Material: | Copper-based sintered alloy |

| Insert: | 1QP-CCMT09T304, 1QP-CCMT32.51 |

| Grade: | DX110 |

| Cutting conditions: | Vc = 300 (m/min) f = 0.05 (mm/rev) ap = 0.1 (mm) Coolant: Wet |

Example #2

| Part: | Transmission parts |

| Material: | A2011 / AlCu6BiPb |

| Insert: | 1QP-VCGT160404-NS |

| Grade: | DX110 |

| Cutting conditions: | Vc = 1,400 (m/min) f = 0.08 (mm/rev) ap = 0.1 (mm) Coolant: Wet |

Example #3

| Part: | Pipe |

| Material: | A5052S / AlMg2.5 |

| Insert: | 1QP-DCGT11T304-NS |

| Grade: | DX110 |

| Cutting conditions: | Vc = 400 (m/min) f = 0.1 (mm/rev) ap = 1 (mm) Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|

|

Aluminum alloys (Si ≤ 12%) |

NS | DX110, DX160 | 300 – 2500 | 0.03 – 0.3 | 0.1 – 2 |

| Without | DX110, DX120, DX140, DX160 |

300 – 2500 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F, DS2005 | 100 – 1200 | 0.1 – 0.5 | 0.05 -5 | ||

| 28 | KS05F, DS2005 | 100 – 1200 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 1000 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 1200 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 1200 | 0.02 – 0.2 | 0.5 – 3 | ||

| Aluminum alloys (Si ≥ 12%) |

NS | DX110, DX160 | 300 – 800 | 0.03 – 0.2 | 0.1 – 2 | |

| Without | DX110, DX120, DX140, DX160 |

300 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX120 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX140 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| Without | DX160 | 400 – 800 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F, DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | ||

| 28 | KS05F, DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 300 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 1200 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 300 | 0.02 – 0.2 | 0.5 – 3 | ||

| Copper and copper alloys | NS | DX110, DX160 | 300 – 1500 | 0.03 – 0.3 | 0.1 – 2 | |

| Without | DX110, DX120, DX140, DX160 |

300 – 1500 | 0.05 – 0.2 | 0.05 – 2 | ||

| AL | KS05F, DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | ||

| 28 | KS05F, DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 | ||

| P | TH10 | 100 – 300 | 0.2 – 0.5 | 0.5 – 4 | ||

| JP | KS05F | 100 – 300 | 0.02 – 0.1 | 0.05 – 2.5 | ||

| JS | KS05F | 100 – 300 | 0.02 – 0.2 | 0.5 – 3 | ||

| Magnesium alloys | Without | DX110, DX120, DX140, DX160 |

400 – 1200 | 0.05 – 0.2 | 0.05 – 1 | |

| FRP | Without | DX160, DX200 | 500 – 1000 | 0.05 – 0.3 | 0.1 – 1 | |

| CFRP | Without | DX160, DX200 | 100 – 700 | 0.05 – 0.3 | 0.1 – 1 | |

| Carbon | Without | DX160, DX200 | 300 – 500 | 0.05 – 0.3 | 0.1 – 1 | |

| Green ceramics | Without | DX160, DX200 | 100 – 200 | 0.02 – 0.1 | 0.1 – 1 | |

| Tungsten carbide (HRA80 – 95) | Without | DX160, DX200 | 5 – 30 | 0.02 – 0.1 | 0.02 – 0.2 | |

| Sputtering targets for semiconductor | Without | DX200 | 10 – 100 | 0.02 – 0.1 | 0.02 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: