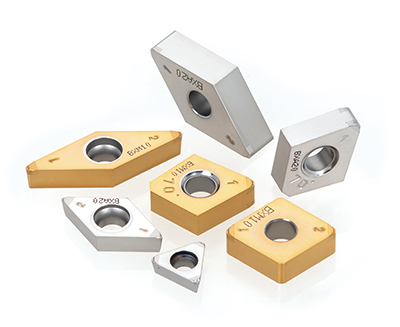

CBN insert with chipbreaker for finishing hardened steel

Innovative 3D chipbreaker on CBN inserts for efficient chip control for finishing hardened steel

Applications & Features

Applications

Features

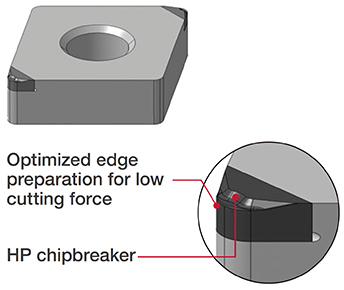

1. New HP chipbreaker For Finishing Hardened Steel

• By separating the chipbreaker from the cutting edge, the cutting force imposed on the cutting edge during machining is significantly reduced, thus providing long tool life.

• The cutting edge preparation is designed to ensure easy cutting at low cutting forces, while maintaining close tolerances with no deviations.

• The HP style chipbreaker, combined with built-in wipers, yields excellent surface quality and good chip control.

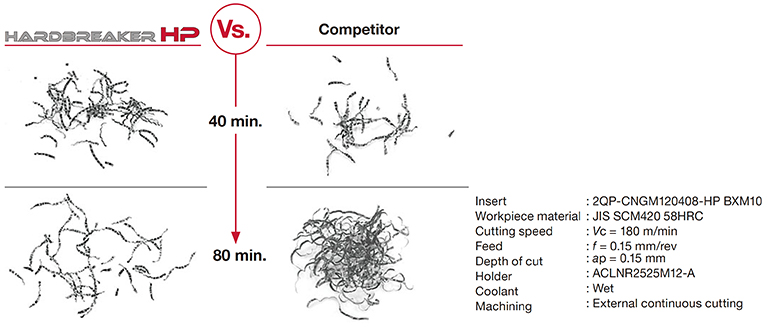

2. Chip control is stable for a long time

Inserts & Grades

Inserts

Main Grades

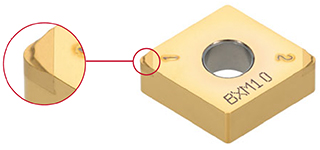

BXM10

![]()

- Coated CBN for excellent performance in high-speed continuous cutting of hardened steel

BXA10

![]()

- First choice for continuous to light interrupted cuts of hardened steel turning

- For cutting speed = 230 m/min or less

BXA20

![]()

- First choice for light to heavy interrupted cuts

- For Vc = 180 m/min or less

Practical examples

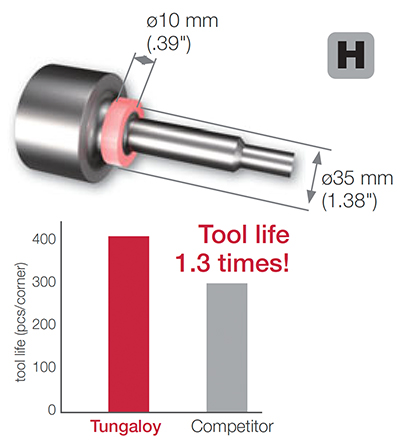

Example #1

Automotive Industry

| Part: | CVJ part |

| Material: | SCR420(JIS) (60HRC) |

| Toolholder: | ACLNR2525M12-A |

| Insert: | 2QP-CNGM120408-HP |

| Grade: | BXM10 |

| Cutting conditions: | Vc = 250 (m/min) (820 sfm) f = 0.20 (mm/rev) (.08 ipr) ap = 0.20 (mm) (.08″) Application: External turning & facing Coolant: Wet Machine: NC lathe |

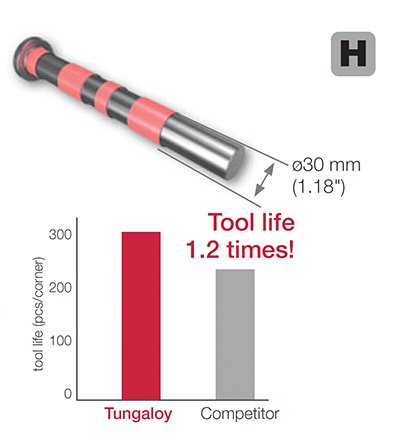

Example #2

Automotive Industry

| Part: | Shaft |

| Material: | SCM420(JIS) (59HRC) |

| Toolholder: | SDJCR2525M11 |

| Insert: | 2QP-DCGT11T304-HP |

| Grade: | BXM10 |

| Cutting conditions: | Vc = 120 (m/min) (394 sfm) f = 0.05 (mm/rev) (.002 ipr) ap = 0.20 (mm) (.08″) Application: External turning Coolant: Wet Machine: NC lathe |

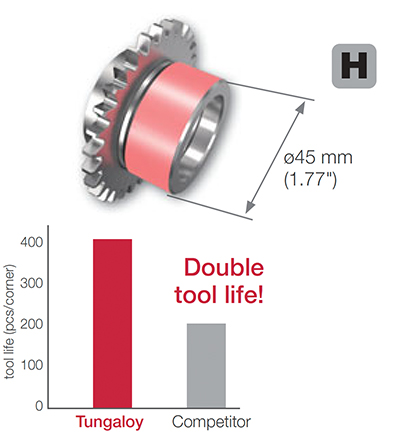

Example #3

Automotive Industry

| Part: | Sprocket |

| Material: | SCM415(JIS) (55HRC) |

| Toolholder: | ACLNL2020K12-A |

| Insert: | 2QP-CNGM120404WL-HP |

| Grade: | BXA20 |

| Cutting conditions: | Vc = 120 (m/min) (394 sfm) f = 0.05 (mm/rev) (.002 ipr) ap = 0.10 (mm) (.04″) Application: External turning Coolant: Wet Machine: NC lathe |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report:

Metric

Imperial

Main product report_No. 518-US