New CBN grade for sintered alloys

Provides superior process security during finish machining of sintered alloys

Applications & Features

Applications

Features

1. Application range

2. Grade properties

– High cBN-content grade for superior wear resistance

– Composed of sub-micron sized fine cBN grains, the grade allows for excellent edge line security, which eliminates burr formation and surface plucking during machining

– Incorporating unique binder material, the grade provides increased interfacial bonding between the cBN grains and binder, allowing superior fracture resistance

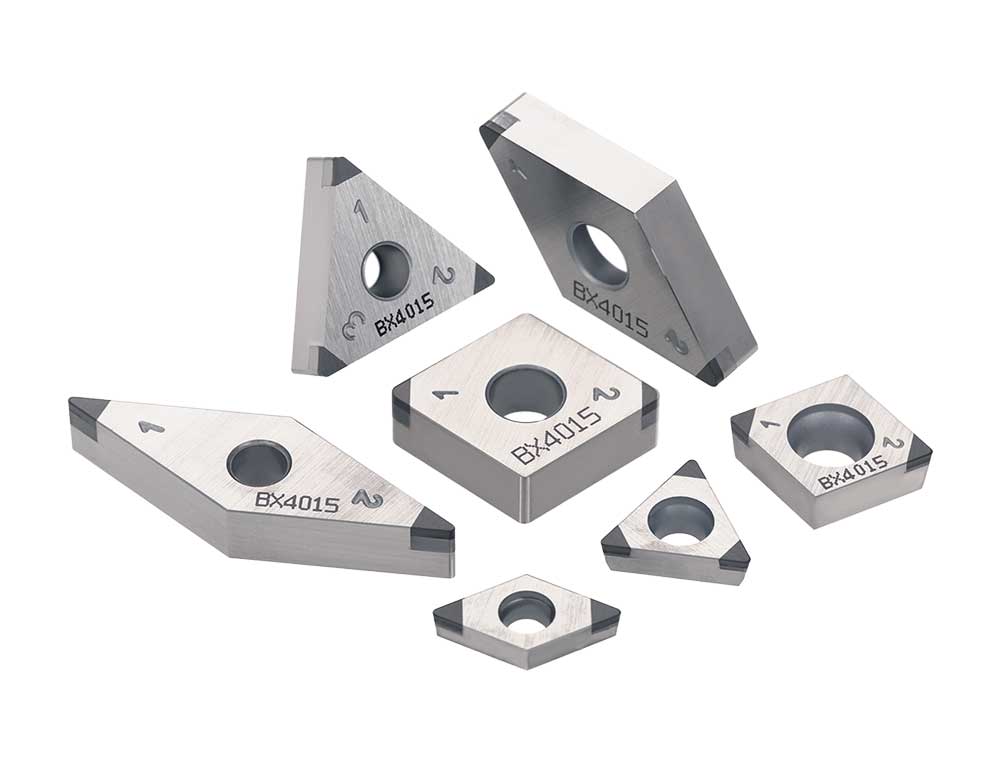

Grades

BX4015

For Shintered alloy

Provides excellent performance in continuous to light-interrupted cuts of sintered alloy parts

Practical examples

Example #1

| Part: | Sprocket |

| Material: | Iron-based sintered alloy |

| Insert: | 3QP-TNGA160408F |

| Grade: | BX4015 |

| Cutting conditions: | Vc = 55(m/min) f = 0.08 (mm/rev) ap = 0.3 (mm) Coolant: Wet |

Example #2

| Part: | Sprocket |

| Material: | Iron-based sintered alloy (partly hardened) |

| Insert: | 3QP-TNGA160408E |

| Grade: | BX4015 |

| Cutting conditions: | Vc = 218(m/min) f = 0.16 (mm/rev) ap = 0.13 (mm) Coolant: Wet |

Standard cutting conditions

| Application | Workpiece materials | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Sintered alloy | General sintered alloy | 10 – 300 | 0.05 – 0.5 | 0.01 – 0.3 |

| High density sintered alloy | 10 – 300 | 0.05 – 0.5 | 0.01 – 0.3 | |

| Sintered-hardened alloy | 10 – 180 | 0.05 – 0.3 | 0.01 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: