Iwaki, Japan – September, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its Hardbreaker Series, now featuring a new HP chipbreaker insert with a 0.2 mm nose radius in BXA20 grade, offering superior chip control and wear resistance for high-hardness steel machining.

Challenges and Trends

In recent years, there has been a growing demand for higher precision in the machining of automotive and precision machinery components. In particular, the need for finishing operations on high-hardness steels with small corner radius (R) specifications is increasing. However, until now, there have been no CBN inserts with a breaker that support a nose radius of 0.2 mm, making chip control difficult and resulting in challenges related to productivity and tool life. To meet these needs, machining sites require more precise and stable cutting performance.

Product Overview

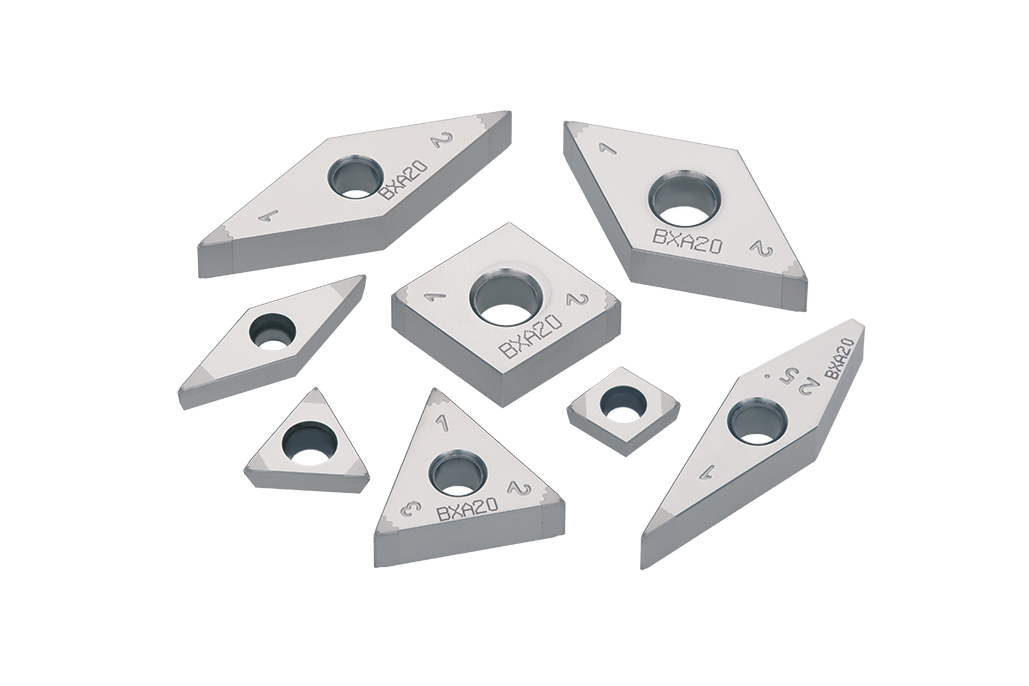

The Hardbreaker Series, ideal for machining hardened steels and high-hardness materials, is a CBN insert lineup that combines excellent chip control and wear resistance. Its three-dimensional breaker design enables a wide range of internal and external turning applications, delivering high-precision and stable surface finishes.

Benefits and Features

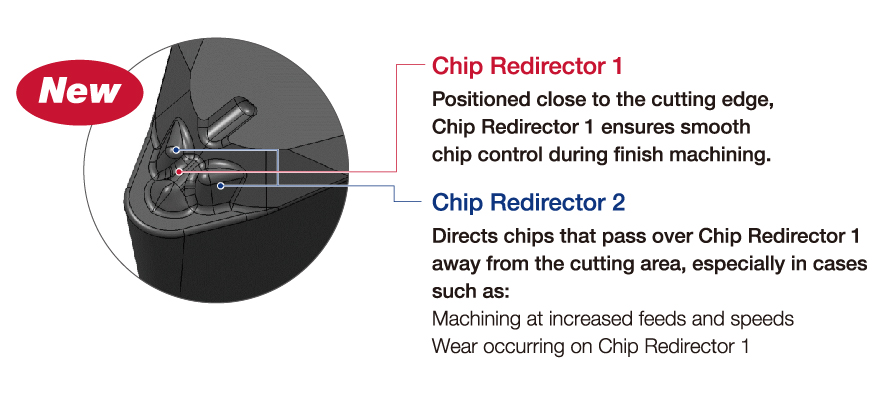

Feature 1: Improved Chip Control and Stability

– The dual-stage breaker protrusion structure ensures reliable chip control even in low depth-of-cut (ap) conditions.

– The first protrusion initiates chip breaking close to the cutting edge, enabling stable chip evacuation from the beginning of the machining process.

– The second protrusion compensates for wear on the first protrusion and changes in chip formation, maintaining chip control performance throughout the operation.

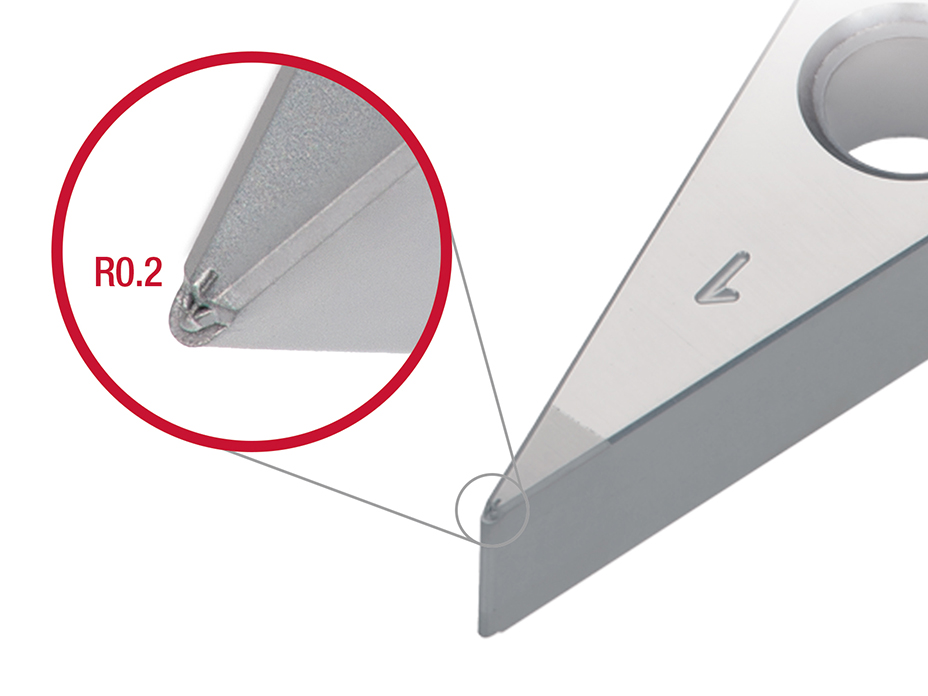

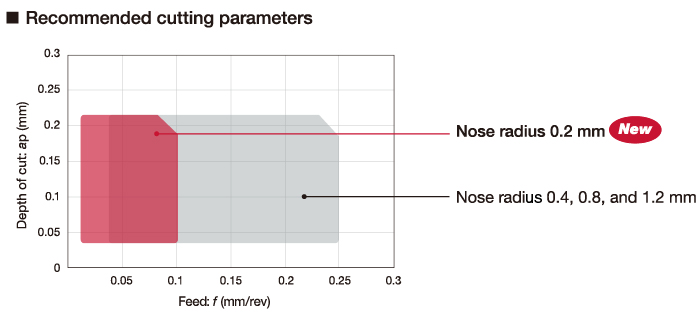

Feature 2: Addition of Nose Radius R0.2 for Precision Machining

– The HP chip breaker line has been expanded to include a nose radius of R0.2, supporting smaller-diameter and high-precision machining.

– Enables stable cutting even at small depths of cut, making it ideal for precision component machining.

Feature 3: Adoption of Well-Balanced Grade BXA20

– The BXA20 grade offers an excellent balance of wear resistance and fracture toughness.

– Contributes to longer tool life and stable machining, improving overall production efficiency.

– Suitable for a wide range of work materials, making it a highly versatile choice for general-purpose applications.

Cutting Performance

Success Stories

IMPROVED TOOL LIFE

BXA20 insert with HP chipbreaker allowed excellent chip control and provided 4.5x tool life increase over the competitor’s uncoated CBN insert.

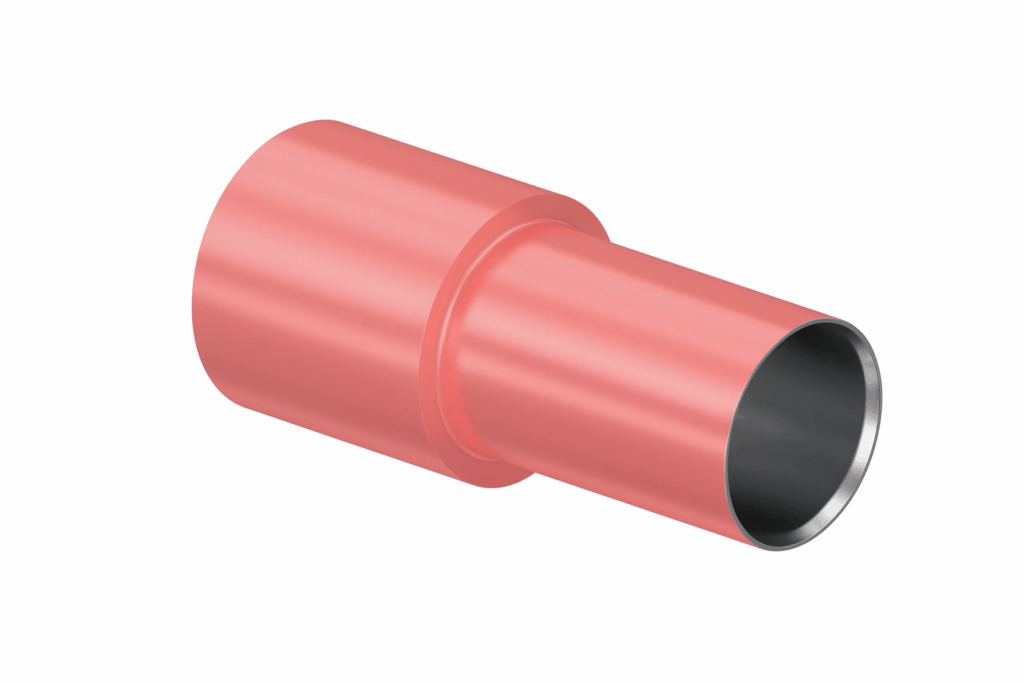

| Industry | Engineering |

| Component | Sleeve |

| Material ISO code | H – Hardened material |

| Work material | SKH40 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | BXA20 |

| TSR No. | 5357T |