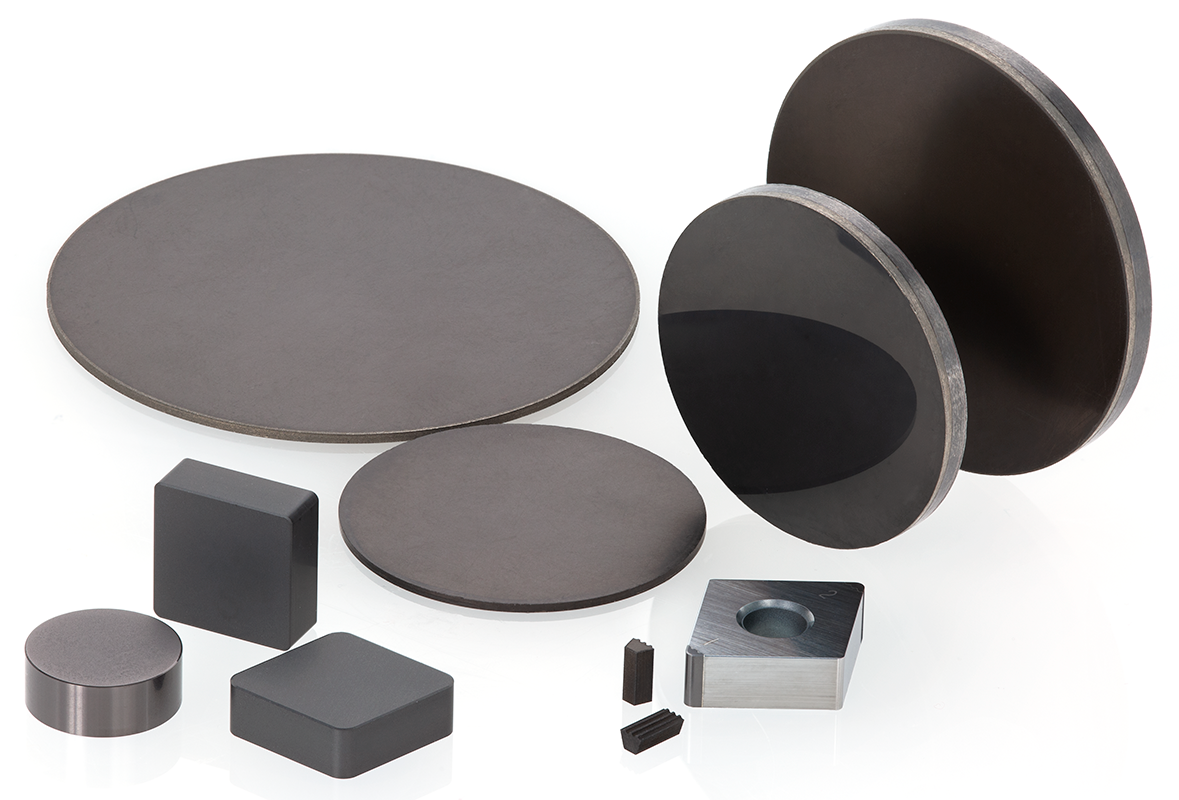

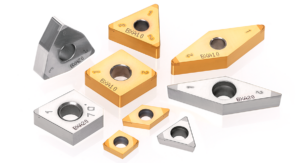

Premium CBN Products

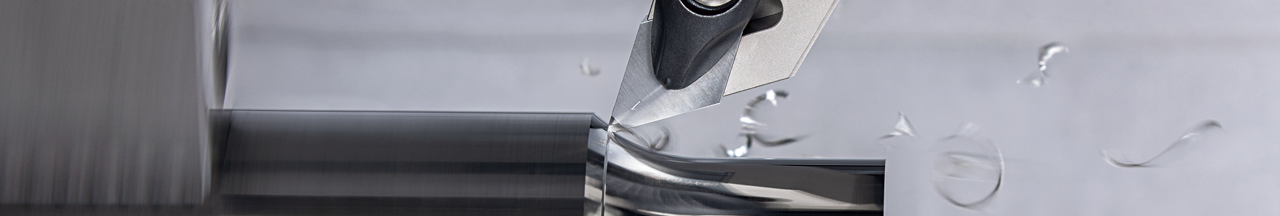

Tungaloy has always been a pathfinder in CBN developments, making hard turning and other CBN applications less hard than it seems…

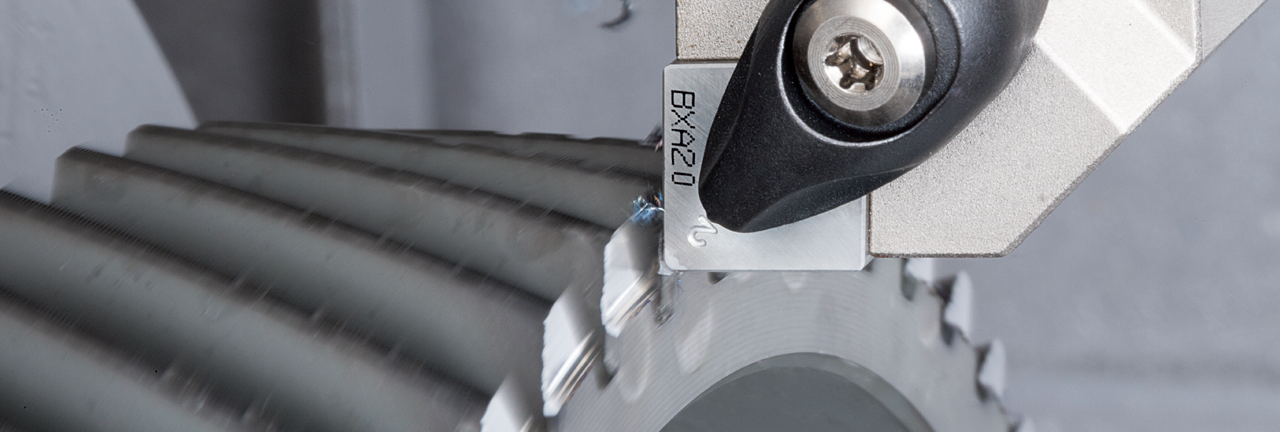

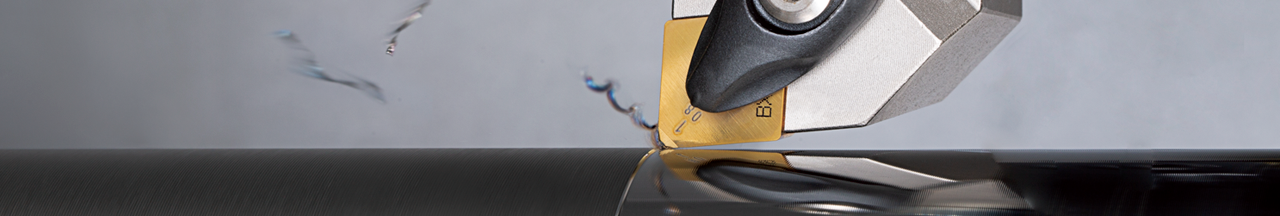

CBN is commonly applied for Hard Turning application but also is used for machining Cast Irons, Superalloys and Sintered Materials. The wide range of Tungaloy´s Premium CBN Products covers all the possible CBN applications.

Tungaloy’s CBN Grades and their properties

Hard Materials

Tungaloy´s Premium CBN Grades for Hard Materials

Tungaloy´s Premium CBN Grades for Hard Materials

| Grade | CBN grain size | CBN content | Binder type | Recommended cutting speed (Vc) | Application range | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fine | Medium | Coarse | Low | Medium | High | Ceramic | Metal | |||

| BM05M | ● | ● | ● | 200 – 350 m/min 656 – 1148 sfm |

|

|||||

| BXA10 | ● | ● | ● | 100 – 230 m/min 328 – 754 sfm |

|

|||||

| BXA20 | ● | ● | ● | 60 – 180 m/min 197 – 590 sfm |

|

|||||

| BXA30 | ● | ● | ● | 50 – 180 m/min

164 – 590 sfm |

|

|||||

| BXA40 | ● | ● | ● | 50 – 180 m/min 164 – 590 sfm |

|

|||||

| BR35F | ● | ● | ● | 50 – 150 m/min 164 – 492 sfm |

|

|||||

| BXM10 | ● | ● | ● | 100 – 300 m/min 328 – 984 sfm |

|

|||||

| BXM20 | ● | ● | ● | 100 – 200 m/min 328- 656 sfm |

|

|||||

| BXC50 | ● | ● | ● | 100 – 200 m/min 328- 656 sfm |

|

|||||

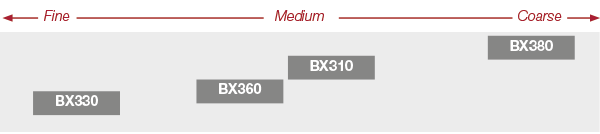

| BX310 | ● | ● | ● | 50 – 200 m/min 164 – 656 sfm |

|

|||||

| BX330 | ● | ● | ● | 50 – 150 m/min 164 – 492 sfm |

|

|||||

| BX360 | ● | ● | ● | 50 – 180 m/min 164 – 590 sfm |

|

|||||

| BX380 | ● | ● | ● | 50 – 120 m/min 164 – 394 sfm |

|

|||||

Cast Iron

Tungaloy´s Premium CBN Grades for Gray Cast Iron

Tungaloy´s Premium CBN Grades for Gray Cast Iron

| Grade | CBN grain size | CBN content | Binder type | Recommended Cutting Speed (Vc) | Application Range | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fine | Medium | Very Coarse | Low | Medium | High | Very High | Ceramic | Metal | |||

| BX910 | ● | ● | ● | 500 – 1200 m/min 1640- 3937 sfm |

|

||||||

| BX930 | ● | ● | ● | 200 – 700 m/min 656- 2296 sfm |

|

||||||

| BX480 | ● | ● | ● | 300 – 2000 m/min 984 – 6561 sfm |

|

||||||

| SBN30 | ● | ● | ● | 300 – 2000 m/min 984 – 6561 sfm |

|

||||||

Tungaloy´s Premium CBN Grades for Ductile Cast Iron

Tungaloy´s Premium CBN Grades for Ductile Cast Iron

Superalloys

Tungaloy´s Premium CBN Grades for HRSA

Tungaloy´s Premium CBN Grades for HRSA

Tungaloy´s Premium CBN Grades for Titanium alloy

Tungaloy´s Premium CBN Grades for Titanium alloy

| Grade | CBN grain size | CBN content | Binder type | Recommended Cutting Speed (Vc) | Application Range | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fine | Medium | Coarse | Low | Medium | High | Very High | Ceramic | Metal | |||

| BX480 | ● | ● | ● | 100 – 200 m/min 328 – 656 sfm |

|

||||||

Sintered Metals

Tungaloy´s Premium CBN Grades for Sintered Metals

Tungaloy´s Premium CBN Grades for Sintered Metals

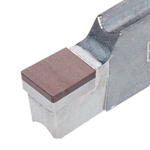

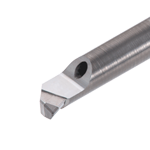

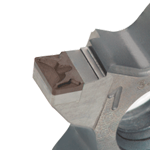

Unique Tungaloy CBN Solutions

TinyMini-Turn CBN Series

CBN carbide boring bars for miniature machining for as small as 2.8 mm bore diameter

Tungaloy’s Knowledge

The uniqueness of Tungaloy´s CBN

CBN grain sizes and their effects on surface roughness

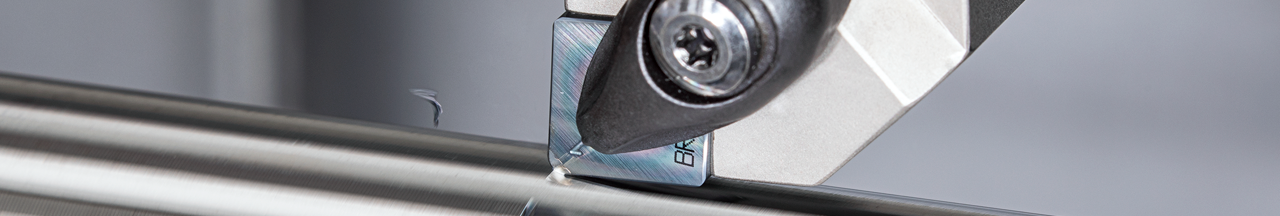

Fine grain (Grain size: ≤ 1 μm)

Fine-grain CBN grades

Sharp and uniform cutting edge

Better surface finish quality

Roughness (Rz < 1.6 μm)

Coarse grain (Grain size: 3 – 6 μm)

Coarse-grain CBN grade

Strong bond between grains

Higher speeds

and feeds can be applied

Roughness (Rz < 6.3 μm)

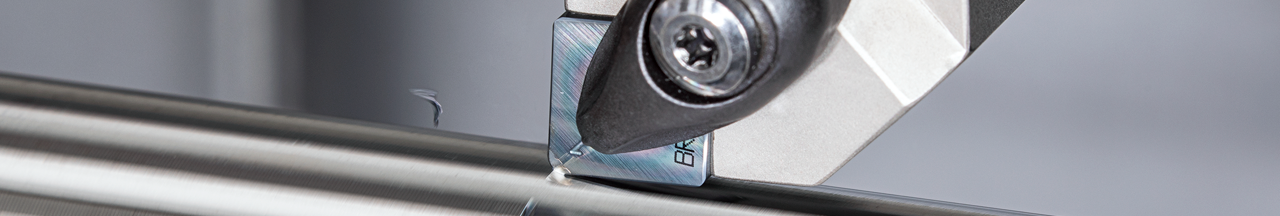

CBN inserts are generally used in a finishing process. A CBN insert grade with coarse abrasive grains will output a rough surface and may not be able to achieve the surface quality required. To achieve superior surface quality of Rz = 3.2 or better, always use a fine grain CBN insert.

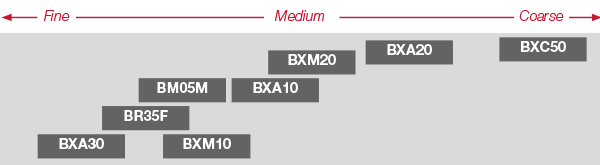

Grain Size – Coated Grades

Grain Size – Uncoated Grades

Made by Tungaloy

Tungaloy is the market leader of CBN Blanks

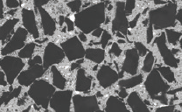

Carefully-selected micron-sized cubic boron nitride powers are sintered with a ceramic or metallic binder under high-temperature, high-pressure (HTHP) environment of over 5 GPa (over 725,189 psi) at 1400 °C -1500 °C (2552 °F – 2730 °F) in Tungaloy’s latest sintering equipment. The CBN blanks will then undergo strict quality screening before being fabricated into CBN inserts.

Tungaloy welcomes customers to collaborate with its Advanced Materials Team to develop customized CBN grades perfectly tailored to the customer’s specific hard turning needs. Tungaloy offers a high level of performance in the most challenging hard turning applications but can also bring these unique products to the customers in a short time span.