Applications & Features

Applications

Features

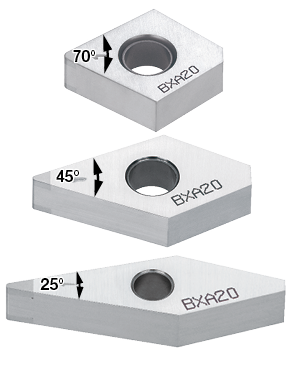

New CBN inserts for general turning

- GNGA insert with 70° corner angle

- FNGA insert with 45° corner angle

- Smaller corner angle provides the insert with greater clearance between the insert flank and workpiece surface, allowing better chip flow and evacuation.

- Enables greater D.O.C. in face turning applications in which the insert is pulled outward (fed away from the workpiece center).

- YNGA insert with 25° corner angle

- Allows undercutting, V grooving, and other applications that are not possible with traditional V inserts.

High versatility

- Existing ISO turning toolholder can be used for these inserts.

- For GNGA insert: Use the holder for CNxx1204 insert

- For FNGA insert: Use the holder for DNxx1504 insert

- For YNGA insert: Use the holder for VNxx1604 insert

- No offsets needed compared to ISO inserts, due to same geometry of cutting edge position.

- Double sided insert with 2 cutting edges.

Inserts & Grades

Inserts

Main Grades

BXA10

![]()

- First choice for continuous to light interrupted cuts of hardened steel turning

- For cutting speed = 230 m/min or less

BXA20

![]()

- First choice for light to heavy interrupted cuts

- For Vc = 180 m/min or less

BXM20

![]()

- Coated CBN for machining hardened steel in a wide range of application area

Practical examples

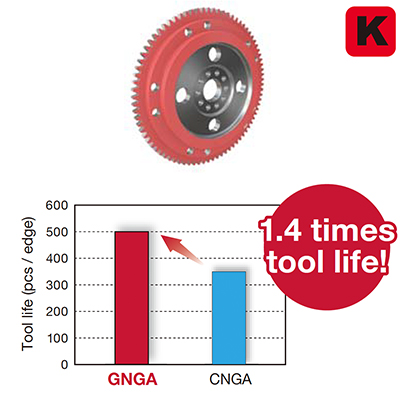

Example #1

Automotive Industry

| Part: | Flywheel |

| Material: | FC250 / 250 |

| Toolholder: | DCLNR2525M12 |

| Insert: | 2QP-GNGA120408 |

| Grade: | BX470 |

| Cutting conditions: | Vc = 500 (m/min) f = 0.10 (mm/rev) ap = 0.20 (mm) Application: Face turning Coolant: External supply |

Example #2

General Engineering

| Part: | Collet |

| Material: | SNCM220 / 20NiCrMo2 |

| Toolholder: | A25R-ACLNR12-D320 |

| Insert: | 2QP-GNGA120408 |

| Grade: | BXM20 |

| Cutting conditions: | Vc = 70 (m/min) f = 0.06 (mm/rev) ap = 0.20 (mm) Application: Internal turning Coolant: Dry |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report:

Metric

Imperial

Main product report_No. 510-US