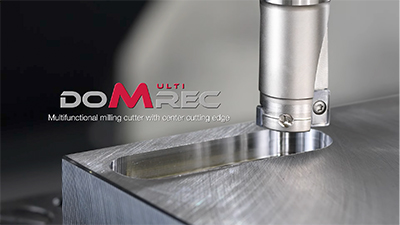

Multifunctional milling cutter with center cutting edge

All-round cutter with center cutting capability provides ultimate machining versatility

Applications & Features

Applications

Features

1. Ultimate versatility

– With center cutting capability, a single cutter can perform a wide array of applications, enabling process and tool integrations for maximum productivity. Dovetail insert clamping ensures for high process security.

Applications capabilities with DoMultiRec

| Insert size | APMX (mm) | Tool dia. DC (mm) |

|---|---|---|

| 08 | 7 | ø16 |

| ø17 | ||

| 10 | 9 | ø20 |

| ø21 | ||

| 12 | 11 | ø25 |

| ø26 |

2. Maximum cost per edge for shoulder cutters with a center cutting edge

– A single insert can be used either for center edge or peripheral edge and can be used twice in each position – four total cutting edges for highest insert economy.

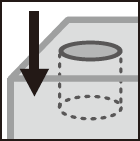

3. Flat hole bottom

– Easy to make hole bottoms as flat as possible. Also makes it suitable for counter boring.

Size 12

| Cutter | : EVLX12M025C25.0R02 (ø25 mm, z = 2) |

| Insert | : LXMU120408PER-MM AH3225 |

| Cutting speed | : Vc = 150 m/min |

| Feed per tooth | : fz = 0.07 mm/t |

| Hole depth | : 5 mm |

| Overhang length | : 45 mm |

| Coolant | : Dry |

Optimized bottom edge design provides hole bottom with flatness.

Inserts & Grades

Inserts

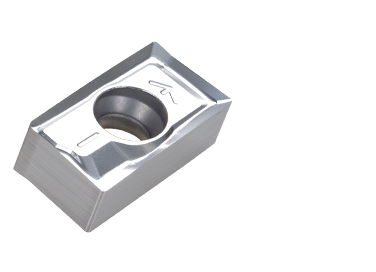

LXMU**-MM

- Maximum depth of cut

– LXMU06: 5 mm

– LXMU08: 7 mm

– LXMU10: 9 mm

– LXMU12: 11 mm

– LXMU16: 14.5 mm

– LXMU19: 18 mm

LXGU**-AM

- Maximum depth of cut

– LXGU06: 5 mm

– LXGU08: 7 mm

– LXGU10: 9 mm

– LXGU12: 11 mm

– LXGU16: 14.5 mm

Main Grades

AH120

![]()

![]()

![]()

![]()

-

Good balance between wear and fracture resistance

-

Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Cutter bodies

Practical examples

Example #1

| Part: | Machine part |

| Material: | Cast stainless steel |

| Cutter: | EVLX12M026C25.0R02 (ø26 mm, z = 2) |

| Insert: | LXMU120408PER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 60 (m/min) fz = 0.07 (mm/t) Vf = 102.8 (mm) ap = 5 (mm) ae =26 (mm) Application: Counterboring, Slotting Coolant: External Overhang length: 40 (mm) Machine: Vertical M/C, BT40 |

Example #2

| Part: | Machine part |

| Material: | SCM420/18CrMo4 |

| Cutter: | EVLX12M026C25.0R02 (ø26 mm, z = 2) |

| Insert: | LXMU120408PER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 118 (m/min) fz = 0.31 (mm/t) Vf = 900 (mm) ap = 2 (mm) ae = 5 (mm) Application: Shoulder milling Coolant: Air blast Overhang length: 100 (mm) Machine: Vertical M/C, BT50 |

Standard cutting conditions

| ISO | Workpiece materials | Hardness | Chip-breakers | Grades | Cutting speed Vc (m/min) | Drilling (ZEFP = 1)(1) |

Shouldering / Helical interpolation(1),(2) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed per revolution f (mm/rev) |

Feed per tooth fz (mm/t) |

|||||||||

| 06 | 08 | 10 / 12 / 16 / 19 | ||||||||

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | MM | AH3225 | 100 – 300 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300 HB | MM | AH3225 | 100 – 250 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | MM | AH3225 | 80 – 180 | 0.03 – 0.06 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.25 | ||

|

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | MM | AH3225 | 80 – 180 | 0.03 – 0.08 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.22 | |

|

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250 HB | MM | AH120 | 100 – 300 | 0.03 – 0.1 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Ductile cast iron FCD400, FCD600, etc. 400-15S, 600-3, etc. |

150 – 250 HB | MM | AH120 | 100 – 250 | 0.03 – 0.08 | 0.05 – 0.15 | 0.05 – 0.2 | 0.05 – 0.25 | ||

|

|

Aluminium alloy Si < 13% |

– | AM | DS2005 KS05F |

400 – 800 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | |

| Aluminium alloy Si ≥ 13% |

– | AM | DS2005 KS05F |

100 – 200 | 0.03 – 0.08 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.3 | ||

|

|

Titanium alloys Ti-6AI-4V, etc. |

– | MM | AH3225 | 20 – 60 | 0.03 – 0.06 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | |

| Superalloys Inconel 718, etc. |

– | MM | AH8015 | 20 – 40 | 0.03 – 0.06 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | ||

|

|

Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50 HRC | MM | AH8015 | 50 – 150 | 0.03 – 0.05 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60 HRC | MM | AH8015 | 40 – 70 | 0.03 – 0.05 | 0.04 – 0.1 | 0.04 – 0.15 | 0.04 – 0.15 | ||

- (1)In the following cases, feed as if the cutter has a single effective cutting edge (ZEFP = 1):

- Hole making

- Helical interpolating for holes with a hole diameter (øD) ≤ 1.25x the tool diameter (DC)

- The axial D.O.C. exceeds APMX2

- (2)The tool is prone to vibration when the tool overhang exceeds 3.5xD and cause poor part quality. Make sure to use the axial cutting depth (ap) that do not exceed the value indicated in the APMX2 column. Also reduce the cutting speed and feed rate to 50% of the recommended speed.

For more information about this product, visit our online e-catalog or download the product report: