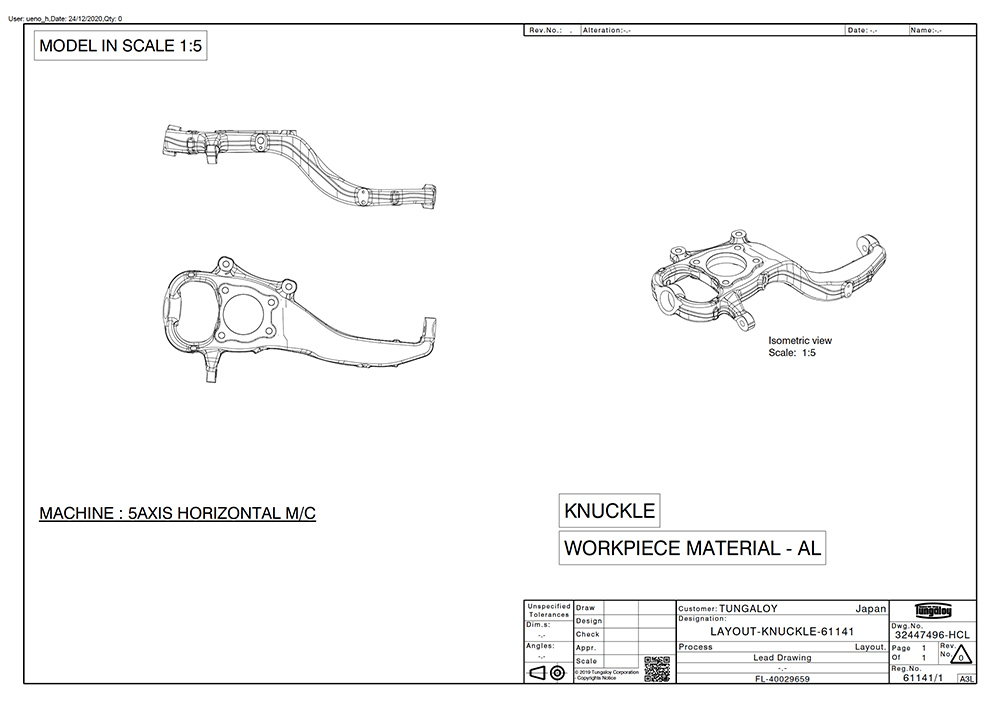

Automotive – Steering Knuckle

The steering knuckle is one of the components that make up the automotive steering system. It contains wheel hubs (or spindles) and attaches to the suspension and steering components of a vehicle to transfer the movements of a steering wheel to the front wheels. Critical to front suspension safety and stability, the component requires quality surface finishes, precision radii, and perfectly machined flatness.

Traditionally the steering knuckle is made of ductile cast iron or forged steel; however, due to recent tendency towards lightweight, more cars are supplied with aluminum knuckles.

Steering knuckles come in all shapes and sizes. With an extensive catalog of products, as well as ability to provide customized tools for drilling, reaming, and slot milling applications, Tungaloy provides optimal solutions for all the requirements.

Machining Challenges

- To use low cutting forces for reduced chatter and improved efficiency at increased cutting speeds and feeds

- To maintain process security with optimal tool geometry for machining complex and less-rigid workpiece

- To achieve top quality and short cycle time, while minimizing cost per part

Key Points

-

Customized tooling solutions

Steering knuckles are usually manufactured in one or two setups on machining centers; therefore, tool suppliers often need to supply custom tools that combine multiple operations in order to improve cycle time, as well as to save limited number of tool positions available in the tool magazine.

Tungaloy is able to provide a range of customized tool solutions for slot milling, boring, drilling, and reaming applications:

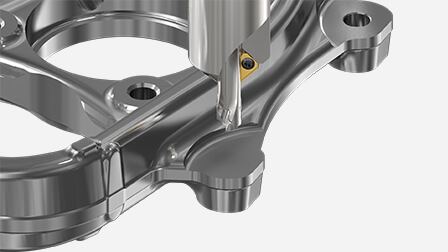

- TungTri: Customized for back-facing of steering arm that requires reduced cutting forces and surface quality. Inserts generate light cutting with no chatter. The cutter body features 90 degree approach angle, allowing a minimum interference when machining close to the workpiece walls

- Solid Taper Reamer: Finish tapered hole.

- Boring tool: By using customized combination tools, a manufacturer can combine multiple operations into a single process and reduce cycle time without compromising the machining result

- SwissBore – Special fine boring tool solution: Digitalized fine boring tool system with setting accuracy of 0.001 mm in diameter. Direct position distance measurement system with no backlash.

- One digital display unit can be used for all boring heads, with back light for clear display

- Boring head with through-coolant supply improves chip control.

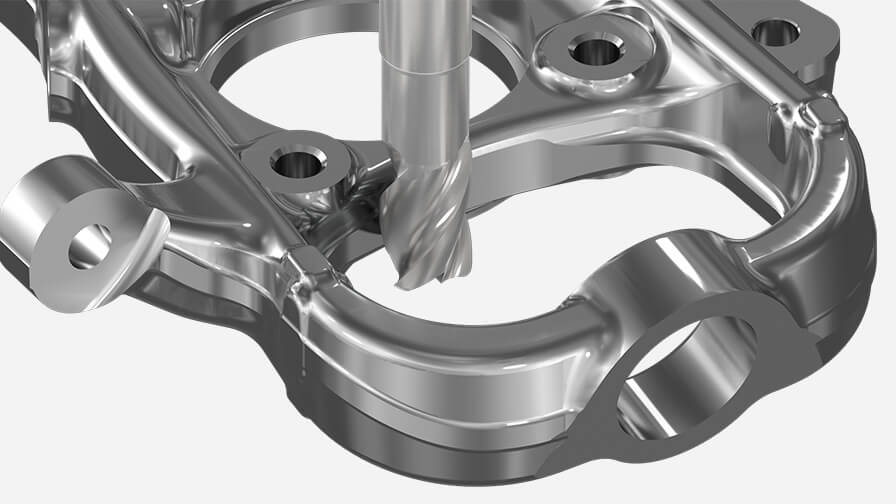

- SolidMeister – VariableMeister / SolidMeister – Specials:

- Sophisticated variable-pitch variable-helix design can operate at a large material removal rate, yielding excellent surface finishing and reduced cycle time, while ensuring process security

- DrillMeister: Reduces tool change time and management costs. DrillMeister with customized chamfering adapter enables simultaneously chamfering and drilling.

- Offers a variety of drill heads

- Provides greater flexibility to address the requests for application-specific tooling and operation merges

Machining Solutions

Drilling

DrillForce-Meister

- Exchangeable tip drill system for improved productivity and process security in producing large diameter holes. Unique tip clamping method allows easy and quick tip exchange without having to remove the tool from the machine spindle.

- Features 180° flat edged tip for productive counterboring operation

- Drill tip can be removed without completely removing the clamping screw off the body

SolidDrill

- Optimum cutting edge geometry combined with most suited grade for superior part quality

Threading

ThreadMilling

- By cutting threads using a rotary tool in a circular ramping movement, the risk of tool breakage and possible part scrap are avoided during the operation, while improving process security.

- Available in solid carbide, exchangeable head, or indexable style

Milling

TungSpeed-Mill

- High speed PCD face milling cutter offering a unique lineup of insert geometries that increase insert reliability for the various needs of non-ferrous applications

- PCD geometries offer fracture resistance in heavy interrupted cuts, long edge for greater depths of cuts, or unique edge for effective burr removal

- Unique CamAdjust insert adjustment method allows easy and quick alignments of insert axial positions

Tung-AluMill

- Innovative V bottom insert ensures reliability and strong performance in high speed cutting. Insert geometry provides productivity in long overhang setup.

- Carbide insert prevents built-up edge producing a mirror finish

- A wide variation of insert nose radii ensures optimum performance in roughing to finishing operations of aluminum

TungMeister

- Exchangeable head end mill series offering an extensive range of milling head profiles

- Excellent repeatability for high part precision

- No setup time – tool changes can be done without removing the shank from the spindle

TungQuad

- Features small-sized square inserts

- Close pitch design for high efficiency machining

- Offers shoulder and chamfer cutter bodies