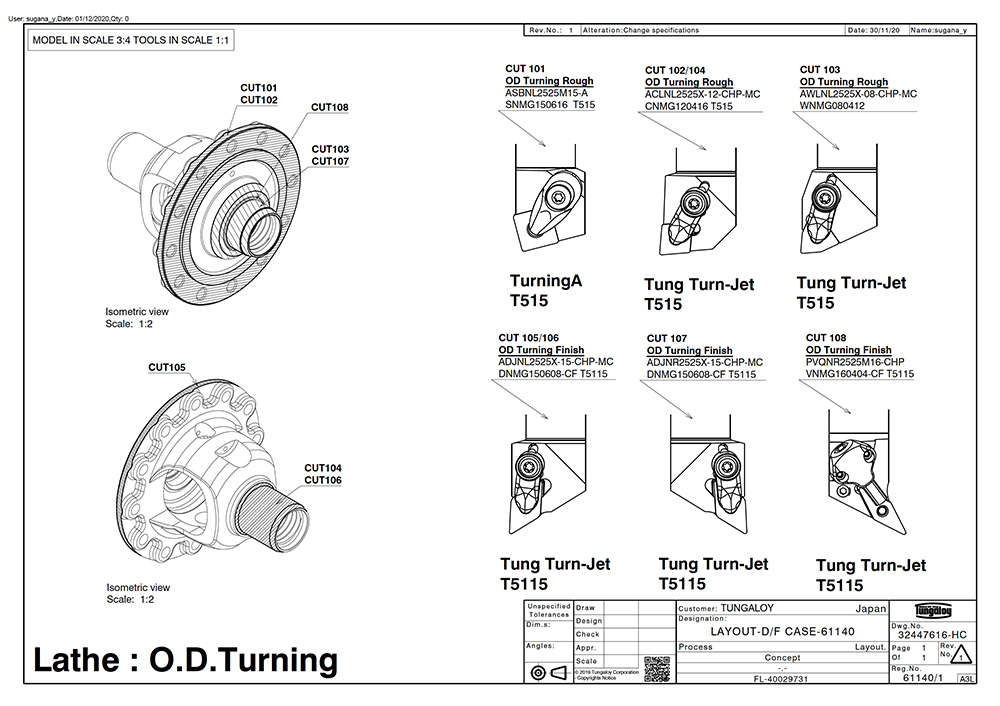

Automotive – Differential Housing

The differential housing is a critical element in the vehicle’s drivetrain, whose objective is to house differential gear assemblies and take torques coming from those gears. Made predominantly from ductile cast iron, this central component will remain indispensable into the future for all propulsion systems — whether internal combustion engine, electronic motor, or hybrid engine; therefore, its production requirements will continue to steadily rise.

Major challenges include cycle time reduction and part precision consistency. On top of meeting the high requirements typical of the automotive industry, the differential housing has an extremely complex shape, posing demanding internal turning process that involves a number of subprocesses.

General Challenges

- To improve machining efficiency and tool life in ductile cast iron machining

- To ensure part precision in individual processes

- To maintain tolerance requirements of the curved surfaces inside the housing

- Cycle time reduction: To maximize machine capacity and minimize downtime

- To drill diverse holes with low cycle times, high quality, and reliability

Key Points

-

Customized tooling for machining spherical and flat faces

- Tungaloy designs and manufactures drop-in style, indexable differential case tooling for dedicated machine-tool equipment. Our application expertise covers many different types of parts and associated materials that require precision tolerances.

-

Drilling diverse holes with minimal cost, low cycle times, high quality, and reliability

- A unique flute design optimizes chip evacuation, and the use of DrillMeister drill heads enables extremely cost-effective process, while maintaining high process stability.

-

Increased tool life and predictability for process security

- T515 is a versatile CVD-coated carbide grade developed specifically for ISO-K cast iron. A thick TiCN+Al2O3 layer combined with a dedicated carbide substrate provides the grade with a great balance of wear resistance and toughness during machining at increased cutting parameters. In addition, the top layer surface is post-treated with PremiumTec technology, enhancing its surface smoothness that resists chipping and welding, while improving surface finishing quality.

Machining Solutions

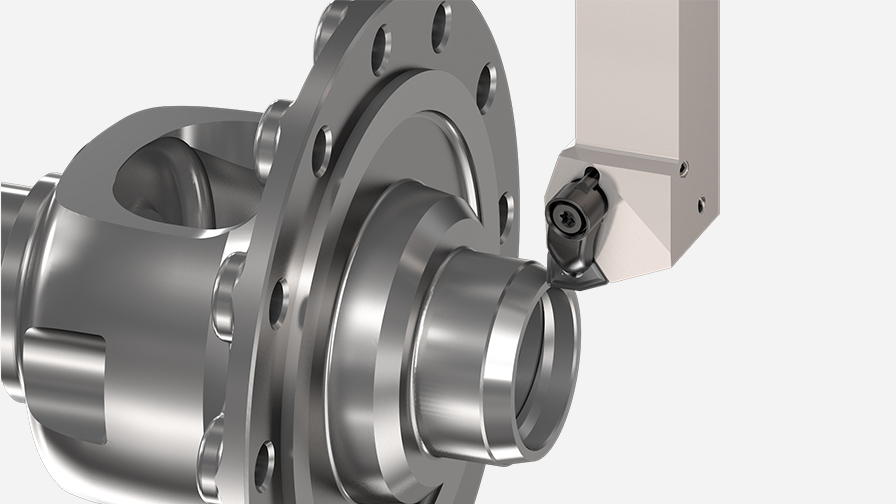

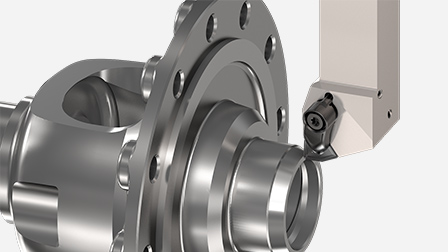

Turning

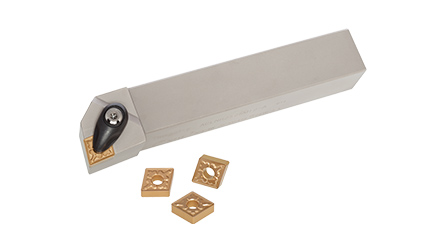

TungTurn-Jet + T515

- Precision coolant turning toolholder, combined with a dedicated grade for cast iron, provides high productivity and process security

- Optimal insert geometry and strong insert design help conquer challenging interrupted cuts in roughing processes

- The holder ensures highly rigid insert clamping and precise coolant delivery to the cutting point

- The grade offers a good combination of the latest coating technology and dedicated carbide substrate, providing extended tool life and better wear prediction

Turning-A

-

- Turning toolholder series with high insert clamping rigidity and repeatability

- Innovative insert clamping design allows high cutting force due to high feed and high D.O.C

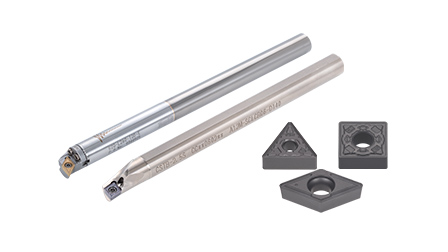

BoreMeister + StreamJet-Bar(special) + T515

- Boring bar with vibration dampening feature.

- Offers various styles of boring heads, either in standard or special, for all ID turning applications

- Through-coolant holder improves chip evacuation

- Eliminates vibration in deep hole boring

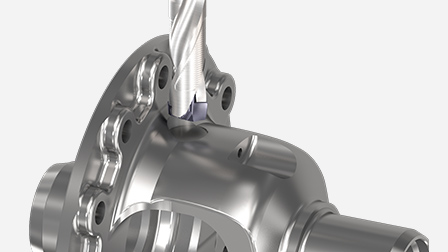

Hole Making

TungMeister

- Exchangeable head end mill series offering an extensive range of milling head profiles

- Excellent repeatability for high part precision

- No setup time – tool changes can be done without removing the shank from the spindle

ReamMeister

- Exchangeable-head reamer for high efficiency reaming and process security thanks to effective coolant delivery to the cutting edges

- No setup time – tool changes can be done without removing the shank from the spindle

- Reduced tool inventory and management

SolidThread – ThreadMilling Series

- Thread milling is a safe and productive method that significantly reduces the risk of scrapping parts

- ThreadMilling tools are available in solid, modular, or indexable tool