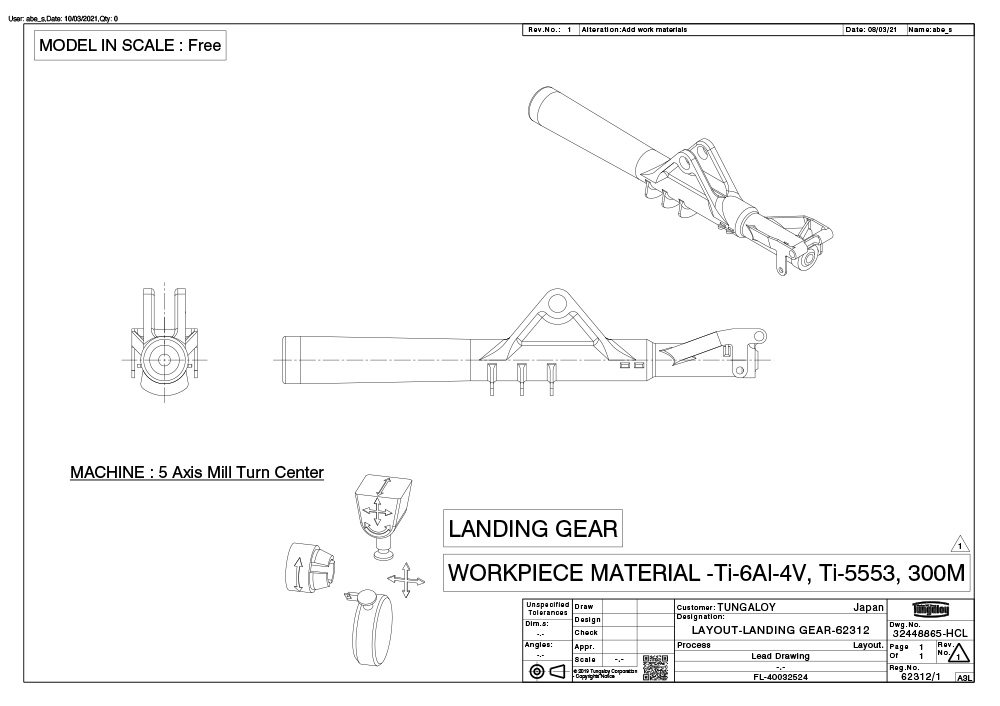

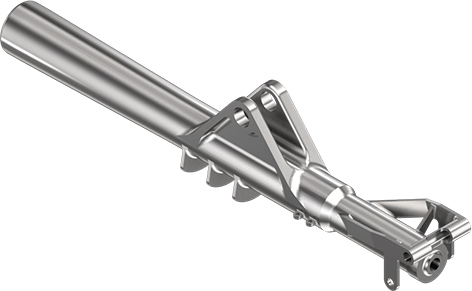

Aerospace – Landing gear

Landing gear is equipment that supports the aircraft’s airframe, which consists of wheels and shock absorbers.

The materials used for the landing gear are required to be rigid for impact during landing and lightweight to improve fuel efficiency.

Typical materials for landing gear are titanium alloys, which have excellent specific strength and excellent corrosion resistance, and special precipitation-hardened stainless steel, which has superior toughness, strength, and scientific stability.

These materials are extremely difficult in terms of machining and are bottlenecks at many machine shops.

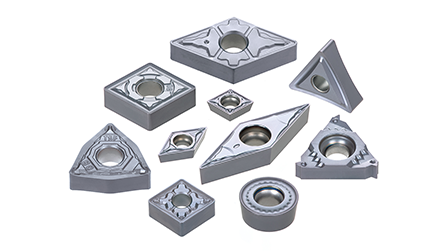

Tungaloy offers the optimum cutting-edge shape to reduce cutting resistance and provides effective solutions for difficult to cut materials.

Tooling concepts

- Improvement of productivity and suppression of chattering

- Selection of multifunctional tools such as high feed cutters that maximize the performance of 5-axis machines

- High feed turning tool with tough cutting-edge is applied to achieve high productivity and reliability improvement of rough turning processes

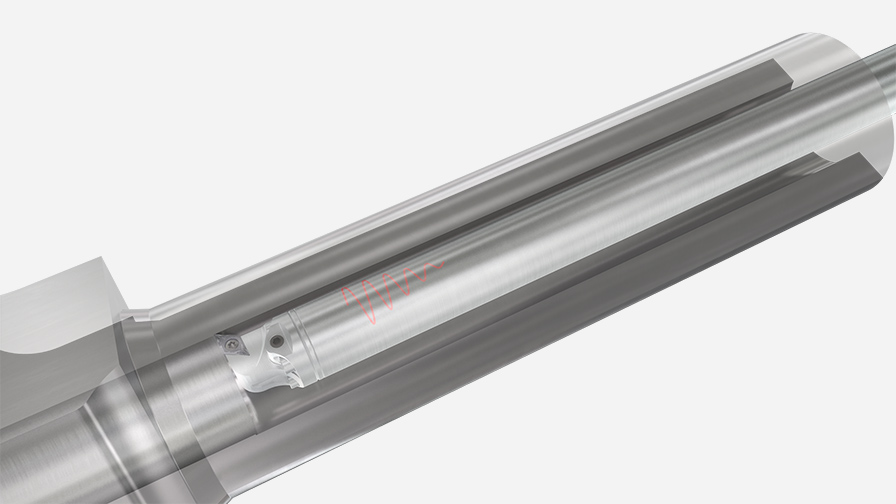

- Prevents chattering and provides high productivity in deep hole internal turning processes

- Applying high pressure coolant holder that is effective for extending the life of difficult- to cut materials

Featured process

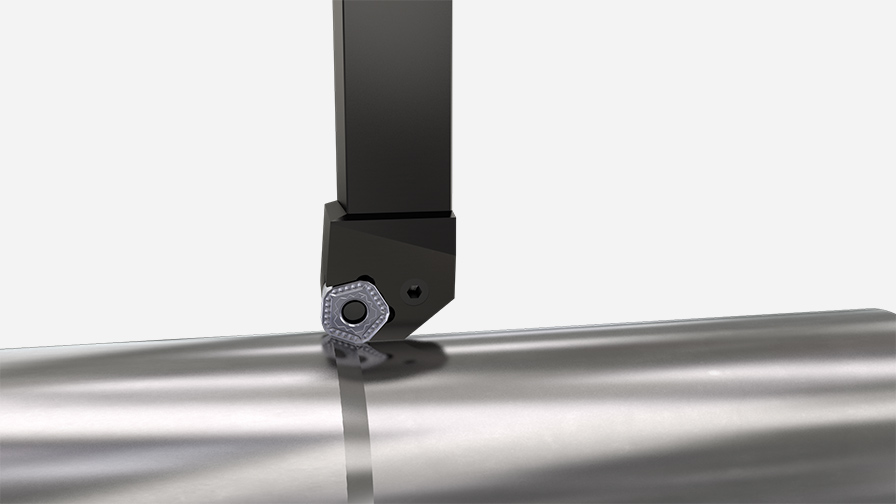

Process 1: Rough external turning

Benefits

- Allow high feed rate due to the low approach angle design that reduces chip thickness

- High-cost efficiency due to double sided insert with 10 edges

- The combination of lever lock clamping system and dove tail insert shape allows both smooth chip evacuation and high clamping rigidity

AH8015

- Extremely long tool life for difficult to cut materials

- Good balance for wear and fracture resistance

AH8015

- Excellent adhesion between coating layer and substrate

- Reduce notch wear , which used to be a problem in heat-resistant alloy machining

- High rake angle reduces cutting force

- Low cutting force and high rigid insert clamping helps to achieve stable milling processes

- Wide chip pocket design allows a high volume of chips to evacuate smoothly

- Enhanced corner design of the insert has high fracture resistance

Process 5: Slot milling with long overhang

Benefits

- Reduced cutting force due to the high inclination helical edge design

- Inclination helical edge and wide chip pocket design improves chip evacuation performance and guarantees stable slot milling even in deep slotting condition which is used to occur chip biting problem

- Economical solution due to the double sided 4 edged insert

- DoTwistBall insert, and clamping design prevents insert rotation which is problem that common round insert cutters have providing stable milling processes

- Original insert design prevents insert rotation

- Excellent chip evacuation performance guarantees stable machining even in pocket milling that is difficult to evacuate chips