Punte ad inserti per foratura profonda

DeepTri-Drill, la serie di punte indicizzabili facili da maneggiare, offre prestazioni eccezionali, una straordinaria efficienza e stabilità nella perforazione di fori profondi.

Applicazioni e caratteristiche

Applicazioni

Caratteristiche

1. Ampia gamma di opzioni per varie applicazioni di foratura profonda

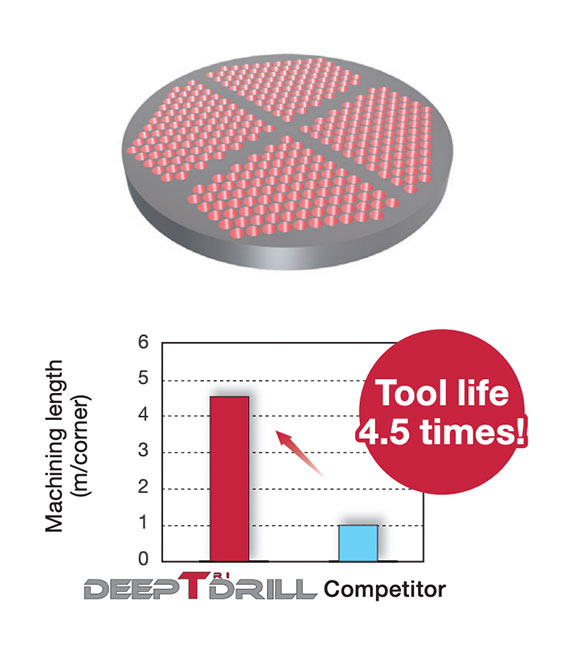

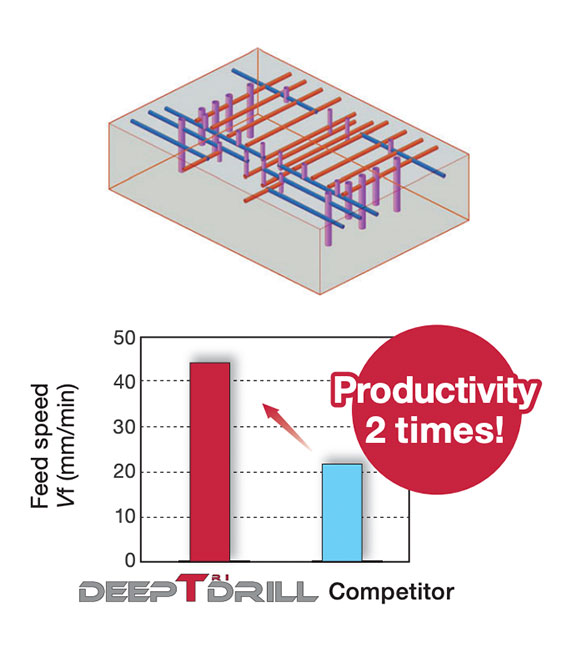

2. Efficienza produttiva

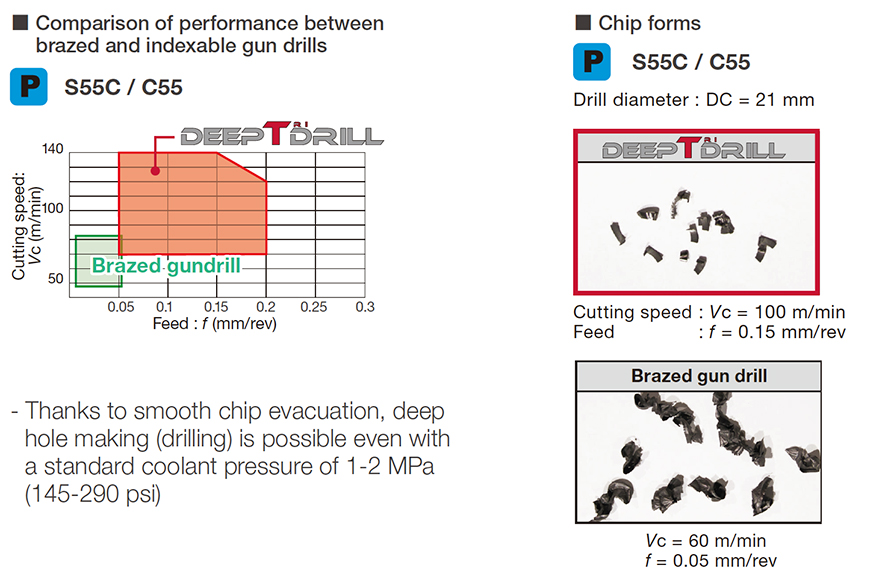

– L’esclusivo rompitruciolo con design “frantuma-trucioli” dentellato sul tagliente assicura un controllo dei trucioli a qualsiasi velocità di avanzamento, soprattutto ad avanzamenti elevati.

– Grazie all’ottima evacuazione trucioli, è possibile realizzare fori profondi anche con una pressione standard del refrigerante di 1-2 MPa (145-290 psi).

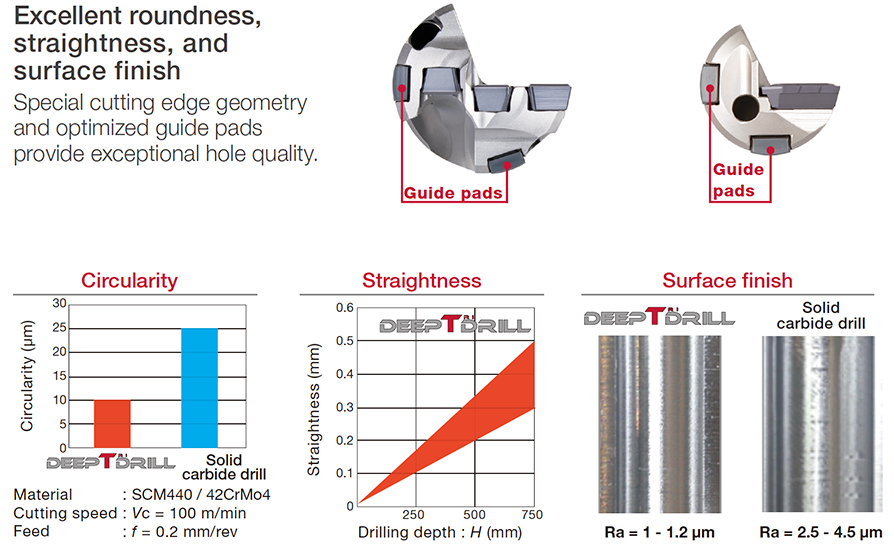

3. Eccellente concentricità, rettilineità e finitura superficiale

– La geometria del tagliente e i pattini di guida garantiscono un’eccezionale qualità del foro.

Inserti e Gradi

Inserti

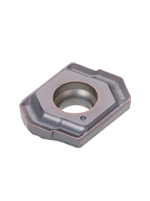

TOHT-NDJ/NDL

- Inserto a 3 taglienti con rompitruciolo dentellato

LOGT-NDJ

- Inserto a 2 taglienti con rompitruciolo dentellato

ZSGT-NDJ

- Inserto ad 1 tagliente con rompitruciolo dentellato

FBM/FBH

- Design rompitruciolo sviluppato e dedicato alla foratura profonda

Pattino di guida

Gradi principali

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- Alta resistenza all’usura

- Progettato per la foratura di diversi materiali

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Buon equilibrio tra resistenza all’usura e alla scheggiatura

- Adatto alla lavorazione di acciaio e acciaio inossidabile in condizioni di taglio generiche

FH3125 (Per i pattini di guida)

- Prima scelta

- Lunga durata dell’utensile grazie all’esclusivo substrato e rivestimento

FH3135 (Per i pattini di guida)

- Elevata resistenza alla frattura

- Prima scelta quando si utilizza un refrigerante solubile in acqua

Corpi punta

Punta ad inserti per foratura profonda

TRLG (ø12 – ø30 mm)

– Per centri di foratura profonda

Esempi di lavorazione

Esempio n. 1

Industria degli scambiatori di calore

| Componente: | Tubo |

| Materiale: | SUS304 / X5CrNi18-9 |

| Punta: | MCTR20.00XM32-10 |

| Inserti: | TOHT090305R-NDL |

| Grado: | AH725 |

| Parametri di taglio: | Vc= 80 (m/min) f = 0,04 (mm/giro) Vf= 53 (mm/min) H = 200 (mm) Refrigerante: sì Macchina: centro di lavoro orizzontale |

Esempio n. 2

Industria degli stampi

| Componente: | Stampo in plastica |

| Materiale: | SKD61 / X40CrMoV5-1 (45 HRC) |

| Punta: | TRLGCH18.00X1500-36A |

| Inserto: | TOHT080305R-NDJ |

| Grado: | AH725 |

| Parametri di taglio: | Vc= 62 (m/min) f = 0,04 (mm/giro) Vf= 44 (mm/min) H = 700 (mm) Refrigerante: sì Macchina: centro di lavoro orizzontale |

Esempio n. 3

Industria automobilistica

| Componente: | Albero |

| Materiale: | SCM420H |

| Punta: | MCTR12.00XM20-20 |

| Inserto: | LOGT060204R-NDJ |

| Grado: | AH725 |

| Parametri di taglio: | Vc= 150 (m/min) f = 0,13 (mm/giro) Vf= 517 (mm/min) øDc = 12 (mm) H = 233 (mm) Refrigerante: sì Macchina: centro di lavoro verticale |

Parametri di taglio standard

Diametro di foratura: DC = ø7,94 – ø9,99 mm

| ISO | Materiale del pezzo | Rompitruciolo | Grado | Velocità di taglio Vc (m/min) |

Avanzamento (mm/giro) |

|---|---|---|---|---|---|

| Acciai a basso tenore di carbonio (C < 0,3) SS400, SM490, S25C, ecc. E275A, C25, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Acciai al carbonio (C > 0,3) S45C, S55C, ecc. C45, C55, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Acciai debolmente legati (C < 0,3) SCM415, 18CrMo4, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | |

| Acciai legati (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.14 | |

| Acciai inossidabili (austenitici) SUS304, SUS316, ecc. X5CrNi18-9, X5CrNiMo17-12-3, ecc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Acciai inossidabili (martensitici, ferritici) SUS430, SUS416, ecc. X6Cr17, X12CrS13, ecc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Acciai inossidabili (Invecchiamento artificiale) SUS630, X5CrNiCuNb16-4, ecc. |

NDJ | AH9130 | 60 – 80 | 0.05 – 0.08 | |

| Ghisa grigia FC250, GG25, 250, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Ghisa sferoidale FCD700, 700-2, ecc. |

NDJ | AH9130 | 60 – 100 | 0.05 – 0.2 | |

| Leghe di alluminio | NDJ | AH9130 | 60 – 100 | 0.05 – 0.18 | |

| Leghe resistenti al calore Inconel 718, ecc. |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | |

| Leghe di titanio Ti-6Al-4V, ecc. |

NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | |

| Acciai temprati ≥ 40HRC |

NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 |

*Refrigerante consigliato per la foratura di acciai inossidabili:

– L’olio refrigerante è la prima scelta

– Il refrigerante solubile in acqua richiede una concentrazione di olio almeno del 20%.

Diametro di foratura: DC = ø10 – ø28 mm

| ISO | Materiale del pezzo | Priorità | Rompitruciolo | Grado | Velocità di taglio Vc (m/min) |

Avanzamento: f (mm/giro) | |||

|---|---|---|---|---|---|---|---|---|---|

| ø10 – ø11,8 | ø11,81 – ø13,99 | ø14 – ø18 | ø18.01 – ø28 | ||||||

| Acciai a basso tenore di carbonio (C < 0,3) SS400, SM490, S25C, ecc. E275A, C25, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.1 | |

| Prima scelta | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Acciai al carbonio (C > 0,3) S45C, S55C, ecc. C45, C55, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Prima scelta | NDJ | AH9130 | 80 – 140 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Acciai debolmente legati (C < 0,3) SCM415, 18CrMo4, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.12 | 0.08 – 0.1 | |

| Prima scelta | NDJ | AH9130 | 80 – 140 | 0.05 – 0.08 | 0.05 – 0.1 | 0.06 – 0.12 | 0.08 – 0.16 | ||

| Acciai legati (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Prima scelta | NDJ | AH9130 | 80 – 120 | 0.05 – 0.14 | 0.05 – 0.16 | 0.07 – 0.18 | 0.08 – 0.2 | ||

| Acciai inossidabili (austenitici) SUS304, SUS316, ecc. X5CrNi18-9, X5CrNiMo17-12-3, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Prima scelta | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Acciai inossidabili (martensitici, ferritici) SUS430, SUS416, ecc. X6Cr17, X12CrS13, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Prima scelta | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Acciai inossidabili (Invecchiamento artificiale) SUS630, X5CrNiCuNb16-4, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.06 | 0.03 – 0.06 | |

| Prima scelta | NDJ | AH9130 | 60 – 100 | 0.05 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.05 – 0.12 | ||

| Ghisa grigia FC250, GG25, 250, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| Prima scelta | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Ghisa sferoidale FCD700, 700-2, ecc. |

Avanzamento inferiore | NDL | AH725 | 50 – 100 | – | – | 0.03 – 0.15 | 0.05 – 0.18 | |

| Prima scelta | NDJ | AH9130 | 80 – 140 | 0.05 – 0.2 | 0.05 – 0.25 | 0.05 – 0.25 | 0.05 – 0.3 | ||

| Leghe di alluminio | Avanzamento inferiore | NDL | AH725 | 80 – 160 | – | – | 0.03 – 0.15 | 0.03 – 0.15 | |

| Prima scelta | NDJ | AH9130 | 100 – 200 | 0.05 – 0.18 | 0.05 – 0.2 | 0.08 – 0.22 | 0.1 – 0.25 | ||

| Leghe resistenti al calore Inconel 718, ecc. |

Avanzamento inferiore | NDL | AH725 | 20 – 50 | – | – | 0.03 – 0.06 | 0.03 – 0.08 | |

| Prima scelta | NDJ | AH9130 | 20 – 50 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

| Leghe di titanio Ti-6Al-4V, ecc. |

Avanzamento inferiore | NDL | AH725 | 30 – 60 | – | – | 0.03 – 0.1 | 0.03 – 0.12 | |

| Prima scelta | NDJ | AH9130 | 30 – 60 | 0.04 – 0.1 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.15 | ||

| Acciai temprati ≥ 40HRC |

Avanzamento inferiore | NDL | AH725 | 40 – 100 | – | – | 0.03 – 0.08 | 0.03 – 0.08 | |

| Prima scelta | NDJ | AH9130 | 50 – 100 | 0.04 – 0.06 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | ||

L’impiego del rompitruciolo NDL è consigliato per la foratura di fori incrociati in condizioni di basso avanzamento.

*Refrigerante consigliato per la foratura dell’acciaio inossidabile:

– L’olio refrigerante è la prima scelta

– Il refrigerante solubile in acqua richiede una concentrazione di olio almeno del 20%.

Diametro di foratura: DC = ø28,01 – ø40 mm

| ISO | Materiale del pezzo | Priorità | Per inserto centrale | Per inserto intermedio | Per inserto periferico | Velocità di taglio Vc (m/min) |

Avanzamento f (mm/giro) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Rompitruciolo | Grado | Rompitruciolo | Grado | Rompitruciolo | Grado | ø28.01 – ø40 | ||||

| Acciai a basso tenore di carbonio (C < 0,3) SS400, SM490, S25C, ecc. E275A, C25, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Acciai al carbonio (C > 0,3) S45C, S55C, ecc. C45, C55, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.3 | ||

| Acciai debolmente legati (C < 0,3) SCM415, 18CrMo4, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.25 | ||

| Acciai legati (C > 0,3) SCM440, SCr420, 42CrMo4, 20Cr4, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.12 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 120 | 0.1 – 0.3 | ||

| Acciai inossidabili (austenitici) SUS304, SUS316, ecc. X5CrNi18-9, X5CrNiMo17-12-3, ecc. |

Avanzamento inferiore | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Acciai inossidabili (martensitici, ferritici) SUS430, SUS416, ecc. X6Cr17, X12CrS13, ecc. |

Avanzamento inferiore | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Acciaio inossidabili (Indurimento per precipitazione) SUS630, X5CrNiCuNb16-4, ecc. |

Avanzamento inferiore | G | AH8015 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH8015 | G | AH8015 | G | AH8015 | 60 – 100 | 0.1 – 0.15 | ||

| Ghisa grigia FC250, GG25, 250, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Ghisa sferoidale FCD700, 700-2, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 50 – 100 | 0.03 – 0.14 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 80 – 140 | 0.1 – 0.35 | ||

| Leghe di alluminio | Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 80 – 160 | 0.03 – 0.2 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 100 – 200 | 0.1 – 0.3 | ||

| Leghe resistenti al calore Inconel 718, ecc. |

Avanzamento inferiore | G | AH8015 | DL | AH725 | G | AH725 | 20 – 50 | 0.03 – 0.08 | |

| Prima scelta | G | AH8015 | G | AH8015 | G | AH8015 | 20 – 50 | 0.06 – 0.13 | ||

| Leghe di titanio Ti-6Al-4V, ecc. |

Avanzamento inferiore | G | AH725 | DL | AH725 | G | AH725 | 30 – 60 | 0.03 – 0.1 | |

| Prima scelta | G | AH725 | G | AH725 | G | AH725 | 30 – 60 | 0.1 – 0.18 | ||

| Acciai temprati ≥ 40HRC |

Avanzamento inferiore | G | AH8015 | DL | AH725 | G | AH725 | 40 – 100 | 0.03 – 0.1 | |

| Prima scelta | G | AH8015 | G | AH8015 | G | AH8015 | 50 – 100 | 0.06 – 0.13 | ||

L’impiego del rompitruciolo NDL è consigliato per la foratura di fori incrociati in condizioni di basso avanzamento.

*Refrigerante consigliato per la foratura dell’acciaio inossidabile:

– L’olio refrigerante è la prima scelta

– Il refrigerante solubile in acqua richiede una concentrazione di olio almeno del 20%.

Per maggiori informazioni su questo prodotto, visita il nostro e-catalog oppure scarica la brochure completa:

Metrico

Corpi punta

Pattino di guida

Imperiale

Corpi punta