Head-changeable drill for drilling large holes

Unique clamping concept and two effective cutting edges on the drill head provide excellent hole quality and high productivity

Applications & Features

Applications

Features

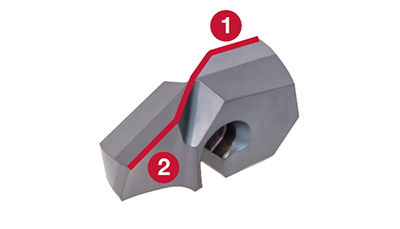

1. Two effective cutting edges

• The drill head with two effective cutting edges provides high productivity and reliability.

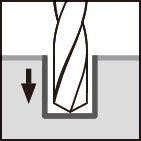

2. Unique clamping system

• The drill head change is possible without removing the drill body from the tool holder or the spindle, eliminating re-adjustments.

• Asymmetric shaped drill head not only secures stability in heavy machining but also error-proofs drill head installation.

• The drill body has a wide supporting area for the drill head for rigid insert clamping.

Inserts & Grades

Inserts

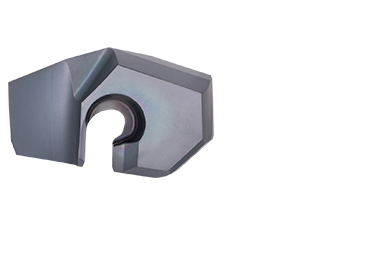

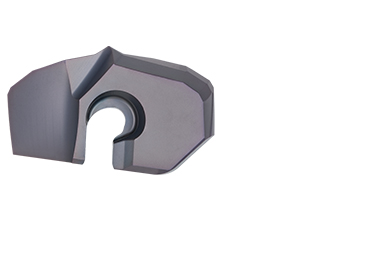

SMP (ø20 – ø41 mm)

- General purpose type

SMF (ø20 – ø41 mm)

- Provides greater resistance to radial forces, improving machining stability during the drilling of irregular surfaces or workpieces with low rigidity

- Coated with wear resistant PVD grade, AH9130

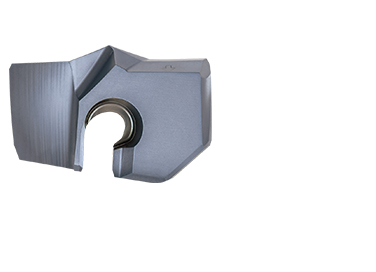

SMC (ø20 – ø33 mm)

- Pre-drilling is unnecessary

- Outstanding drilling stability

- Sophisticated geometry prevents cutting edge fracture and burr formation on the workpiece

Grades

AH725

![]()

![]()

![]()

![]()

-

P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

-

Good balance between wear and chipping resistance

-

Suitable for machining steel and stainless steel under general cutting conditions

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- High wear resistance

- Designed for drilling various materials

Drill bodies

Practical examples

Example #1

General Engineering

| Part: | Gate valve |

| Material: | SUS304 / X5CrNi18-9 |

| Drill: | TIS300F40-5 |

| Head: | SMP300 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 60 (m/min) f = 0.25 (mm/rev) Vf = 160 (mm/min) H = 120 (mm) Machine: Horizontal M/C |

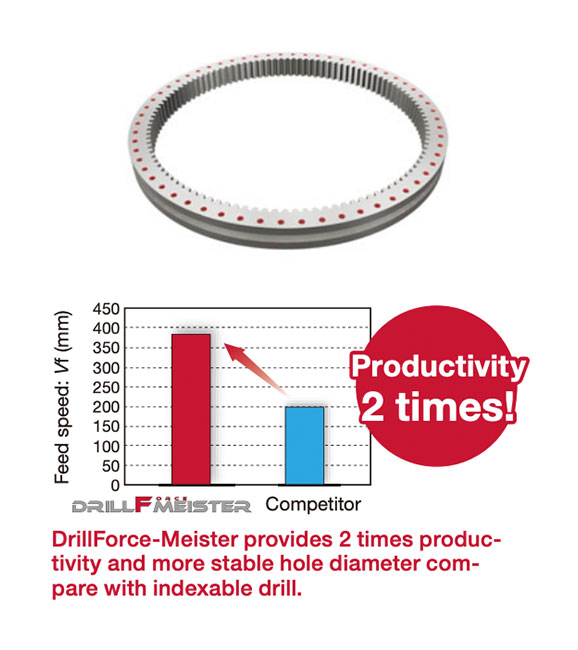

Example #2

Heavy Industry

| Part: | Slewing ring |

| Material: | SCM440 / 42CrMo4 |

| Drill: | TIS330F40-5 |

| Head: | SMP331 |

| Grade: | AH725 |

| Cutting conditions: | Vc = 100 (m/min) f = 0.4 (mm/rev) Vf = 380 (mm/min) H = 150 (mm) Machine: Vertical M/C |

Standard cutting conditions

SMP / SMF

| ISO |

Workpiece materials |

Cutting speed |

Feed: f (mm/rev) |

||

|---|---|---|---|---|---|

| Vc (m/min) | ø20 – 29.9 | ø30 – 35.9 | ø36 – 41 | ||

|

Low carbon steel S15C, S20C, etc. C15E4, etc. |

80 – 140 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

80 – 130 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

| Prehardened steel NAK80, PX5, etc. |

50 – 100 | 0.2 – 0.5 | 0.2 – 0.5 | 0.2 – 0.55 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

40 – 80 | 0.15 – 0.3 | 0.2 – 0.3 | 0.2 – 0.35 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

80 – 180 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 |

| Ductile cast iron FCD400, FCD600, etc. 400-15, 600-3, etc. |

80 – 140 | 0.25 – 0.55 | 0.25 – 0.55 | 0.3 – 0.6 | |

|

Non ferrous materials | 100 – 200 | 0.4 – 0.6 | 0.4 – 0.6 | 0.5 – 0.7 |

|

Heat-resistant alloys Inconel718, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

| Titanium alloys Ti-6AI-4V, etc. |

20 – 50 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 | |

|

Hard materials | 20 – 60 | 0.1 – 0.2 | 0.1 – 0.2 | 0.1 – 0.25 |

SMC

| ISO | Workpiece materials |

Cutting speed |

Feed: f (mm/rev) |

|---|---|---|---|

| Vc (m/min) | ø20 – 33 | ||

|

Low carbon steel S15C, S20C, etc. C15E4, etc. |

80 – 140 | 0.2 – 0.5 |

| Carbon steel and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

80 – 130 | 0.2 – 0.5 | |

| Prehardened steel NAK80, PX5, etc. |

50 – 100 | 0.2 – 0.5 | |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

80 – 180 | 0.25 – 0.55 |

| Ductile cast iron FCD400, FCD600, etc. 400-15, 600-3, etc. |

80 – 140 | 0.25 – 0.55 | |

|

Hard materials | 20 – 60 | 0.1 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: