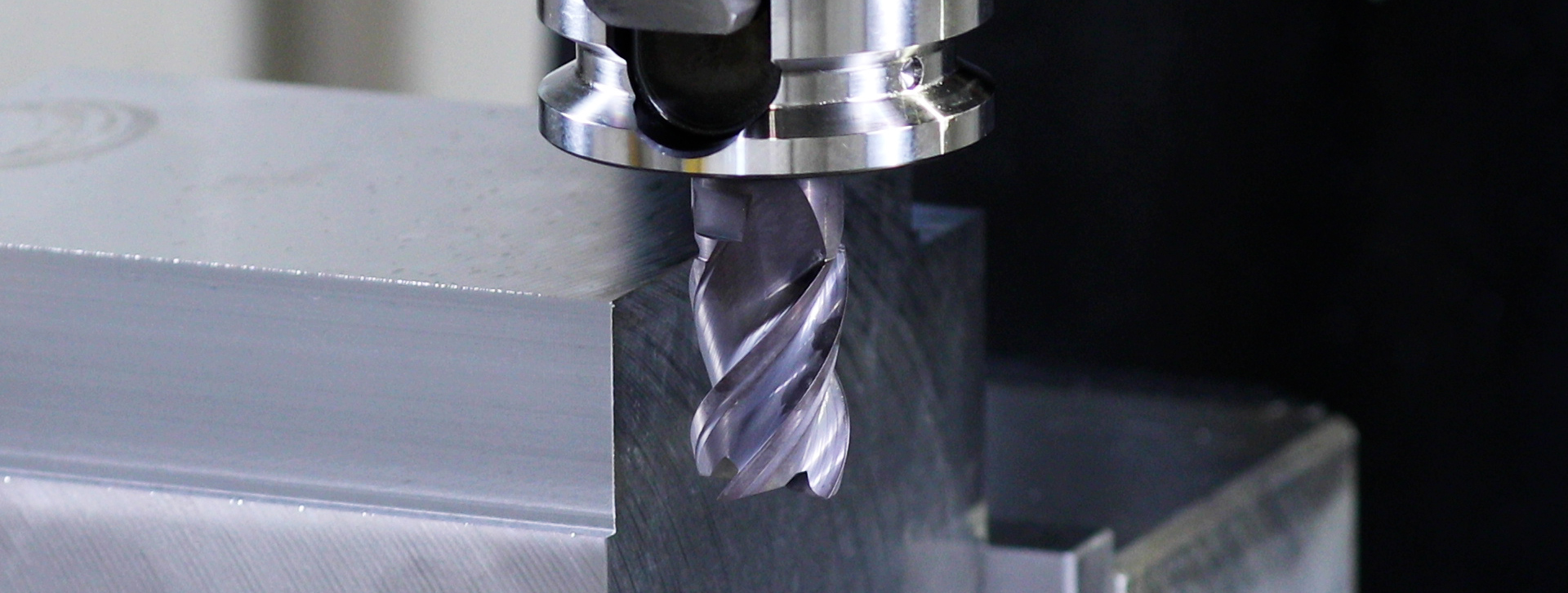

#30-SPINDLE Isn’t the Limitation. Tool Overhang Is.

How TungMeister + TungShort unlock the real capability of small machining centers

Many users of #30-spindle machining centers accept chatter, conservative cutting conditions, and limited capability as unavoidable.

“It’s only a #30” is a common conclusion.

In reality, the limitation is not the machine.

It is the tool overhang.

By shortening the tool assembly, BT30 machines can perform far beyond what is typically expected. This article shows how the TungMeister + TungShort combination reduces overhang by 44%, delivering the same machining range as integrated arbor tools—with approximately 30% lower tooling cost.

The Real Limitation of #30 Machines

#30 platforms have lower overall rigidity than #40 or 50 machines. As tool overhang increases, deflection increases and chatter quickly limits cutting performance. Many users interpret this as the machine reaching its limit.

But the real limitation is not the spindle size.

It is the length of the tool assembly.

Why Tool Overhang Matters More Than Spindle Size

Shorter overhang directly increases rigidity, suppresses vibration, and allows higher cutting conditions.

The practical question becomes:

How short can the tool setup be made on a BT30 machine?

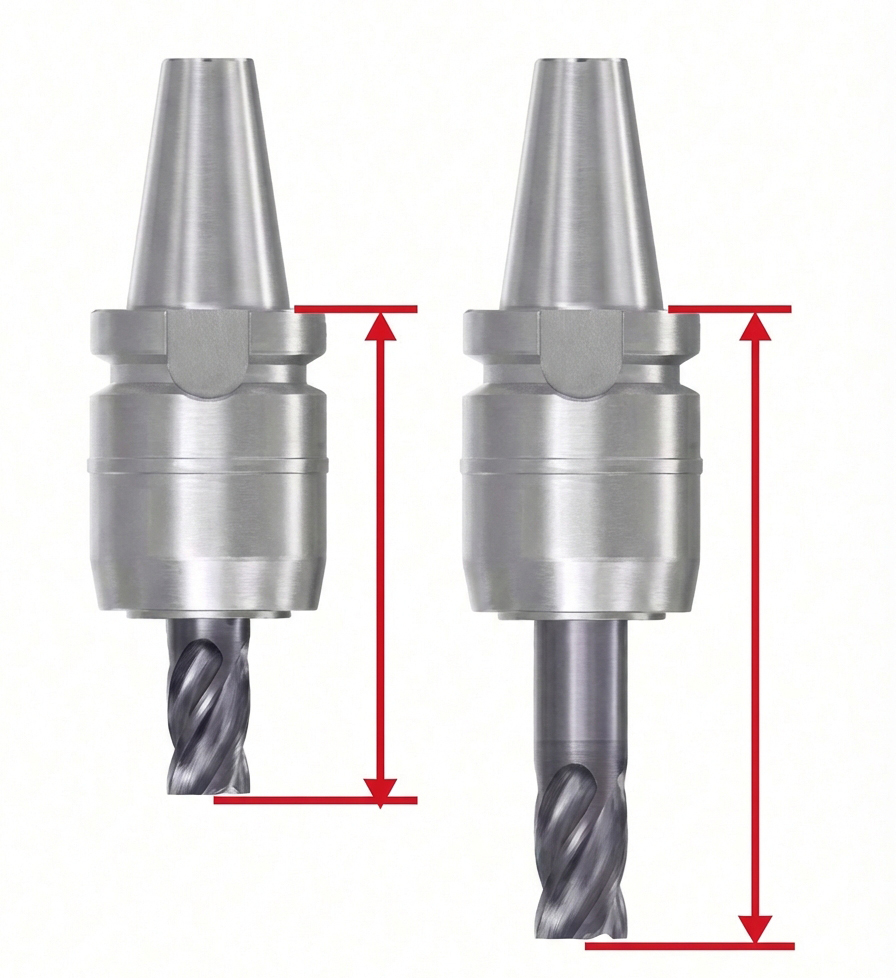

The Practical Solution: TungMeister + TungShort

This is where TungMeister and TungShort change the equation.

- TungMeister is an exchangeable-head end mill system featuring a VER collet-integrated shank design.

- TungShort is an arbor engineered specifically to minimize the gauge line on #30 machines by embedding the collet inside the arbor body.

Unlike conventional collet chucks, where the collet extends beyond the arbor face, TungShort’s internal collet structure drastically reduces the distance from the machine gauge line to the cutting edge.

The result is a tooling assembly far shorter than traditional setups.

| Tool System | Overhang (GL) |

|---|---|

| TungMeister + TungShort | 58mm |

| Integrated Arbor Indexable End Mill | 60mm |

| Solid End Mill + Milling Chuck (Reference) | 103mm |

What About Integrated Arbor Tools?

Integrated arbor holders achieve high rigidity by design, since the arbor and tool body are one piece. They can also achieve short overhang.

Advantages

- Very high rigidity

- Excellent runout accuracy

- Short gauge line (≈60 mm)

Limitations

- High initial cost

- Full replacement required if damaged

- Limited versatility for other tools

They solve the rigidity problem—but at a higher operational cost and lower flexibility.

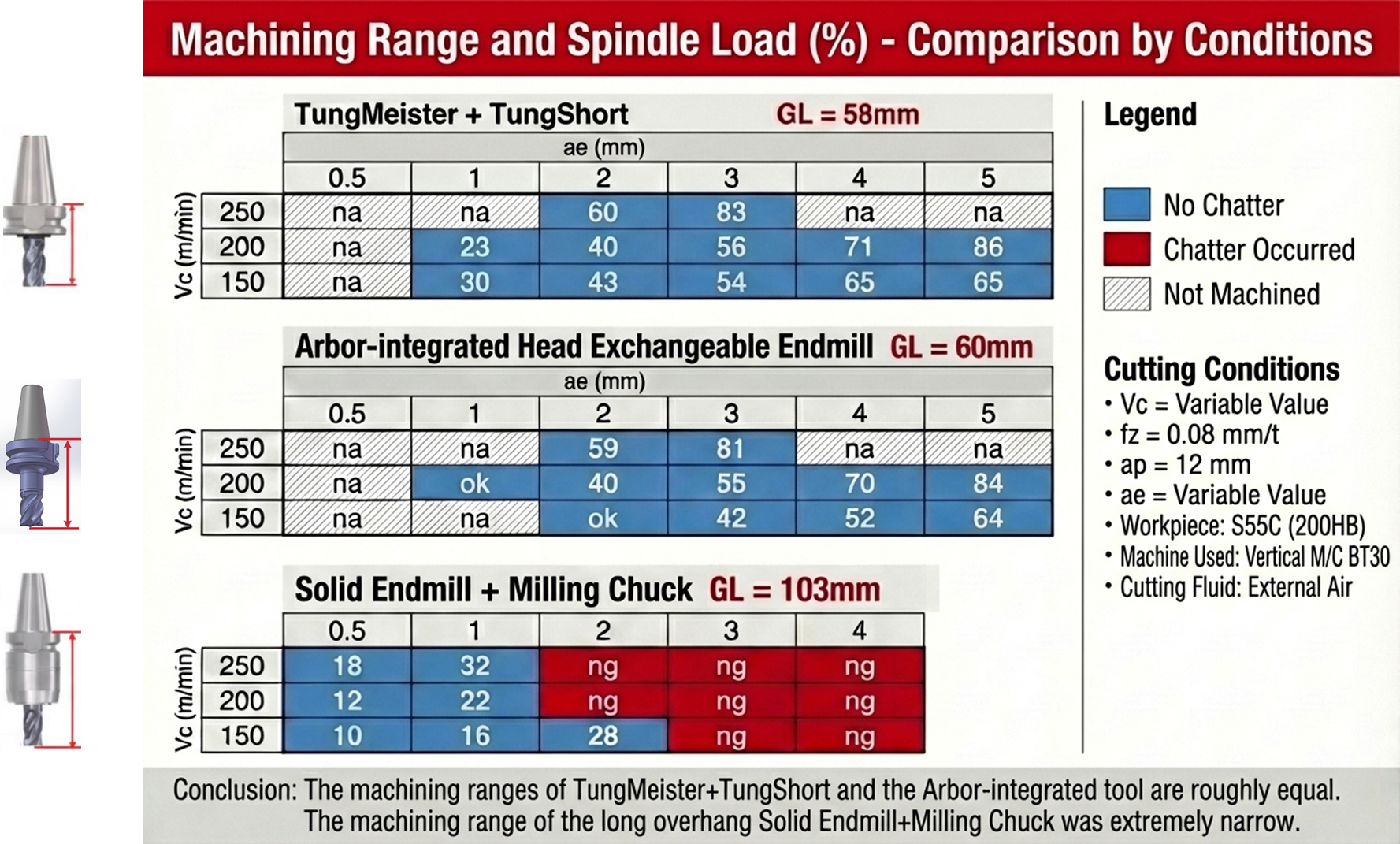

Comparative Test on a BT30 Machine

To verify the real impact of overhang reduction, a machining test was conducted under identical conditions.

Test Conditions

| Machining Method | Shoulder Milling |

|---|---|

| Work Material | S55C (200HB) |

| Machine Used | Vertical Machining Center BT30 |

| Cutting Speed Vc | 150-250 m/min (variable) |

| Feed fz | 0.08 mm/t |

| Axial Depth of Cut ap | 12 mm |

| Radial Depth of Cut ae | 0.5-5 mm (variable) |

| Coolant | External Air |

Tools Compared

| Tool System | Overhang (GL) |

|---|---|

| TungMeister + TungShort | 58mm |

| Integrated Arbor Indexable End Mill | 60mm |

| Solid End Mill + Milling Chuck (Reference) | 103mm |

*All tools are ⌀16 diameter

The results confirmed that TungMeister + TungShort achieved the same machining range as the integrated arbor tool, while the long overhang reference setup showed clear vibration limitations.

Why Choose TungMeister + TungShort?

- Same machining range as integrated arbor tools

- Approximately 30% lower tooling cost

- If damaged, only the head or collet needs replacement—not the entire arbor

- One TungShort arbor can be used with multiple tools via VER collet

- Reduced tool inventory and higher flexibility

Conclusion — Rethinking #30 Capability

#30 machines are often underestimated.

By simply reducing tool overhang, their real capability becomes visible.

TungMeister + TungShort provide:

- 44% shorter overhang

- Equivalent rigidity to integrated arbor tools

- Lower cost, lower risk, higher versatility

Before assuming the machine has reached its limit, optimize the tool setup.

You may discover that your #30 is capable of far more than expected.